Experience

Zero

Defects

Supercharge Your Quality Assurance Process with AI

Inquiry Form

SwitchOn,Inc.

Who We Serve

Trusted by leading manufacturing companies globally to take them to Zero-Defect at a fraction of the cost

What do we do for our Customers

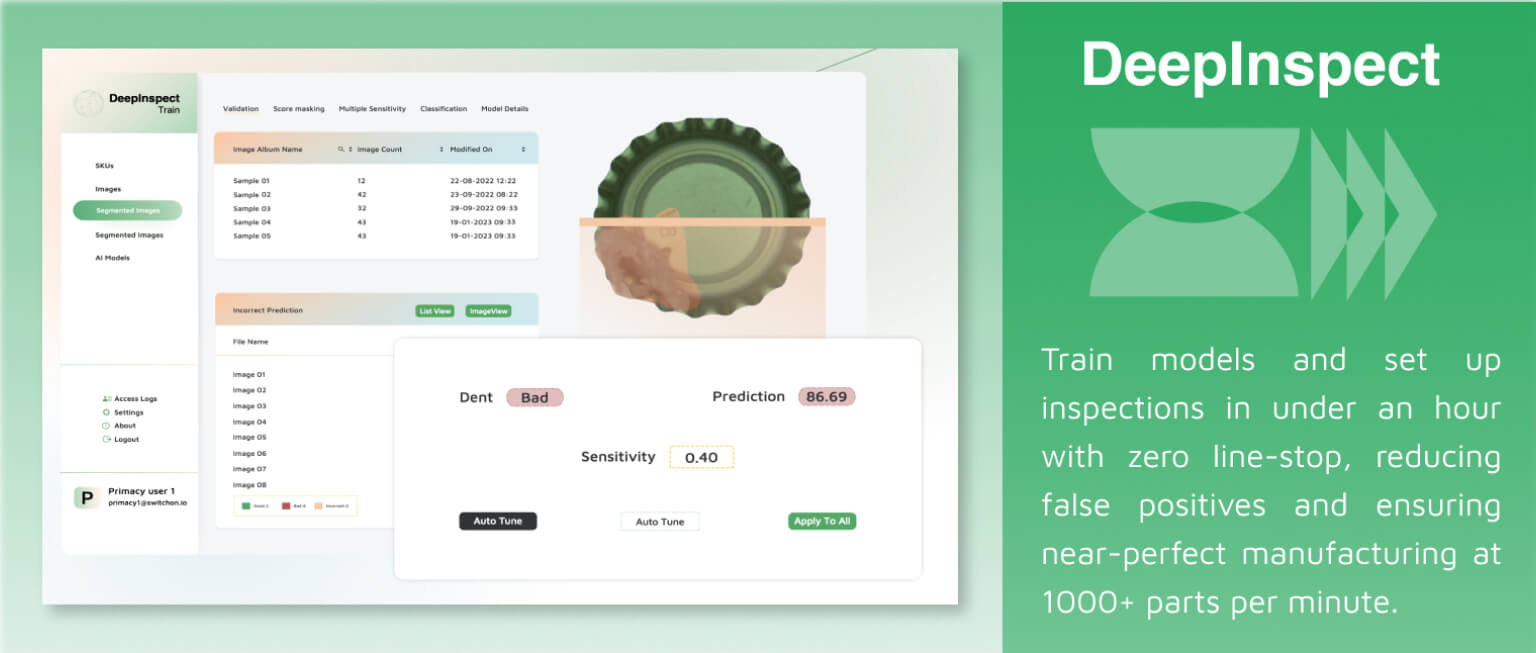

Train a New SKU Within Just 45 Minutes

Detect Defects up to 150 Micron at 99.95%+ Production Accuracy

50%+ Reduction in Cost of Poor Quality

1000+ Parts-per-Minute High-Speed AI Inspection

A Power Packed Solution to Address Any Kind of Visual Defects

Train New Models and Setup Inspection in < 45 Minutes

Zero Line-Stop

DeepInspect

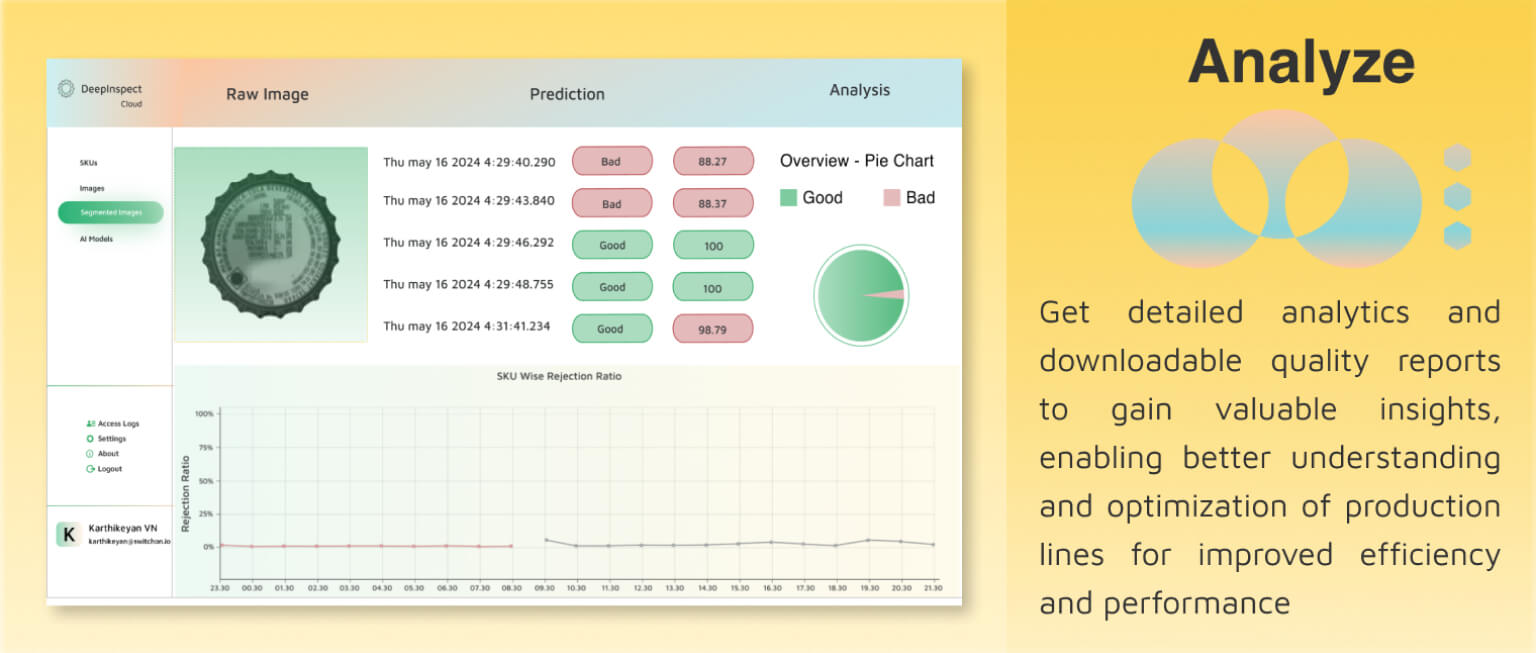

Analyze

Industries We Serve

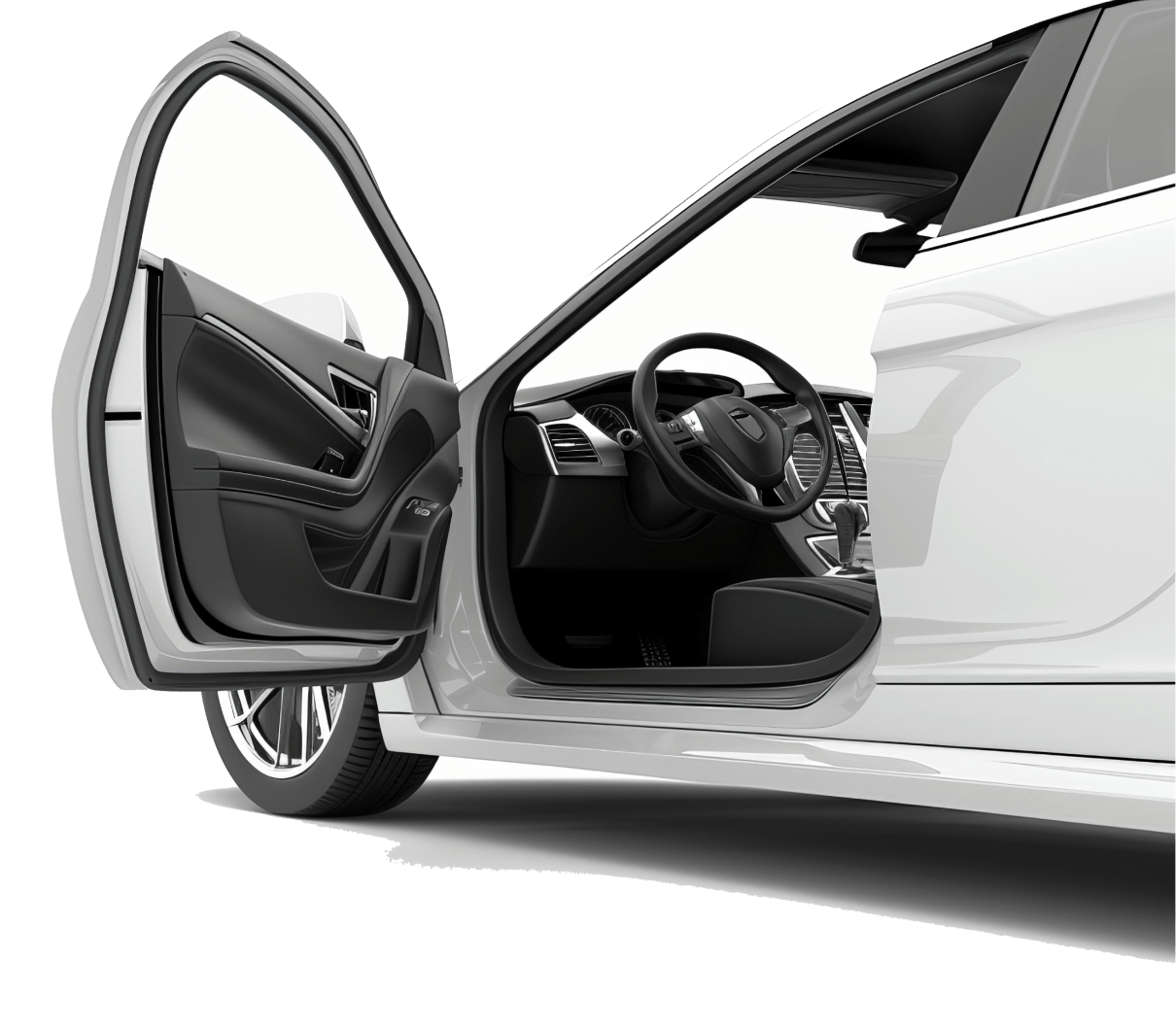

Automotive

Automotive

DeepInspect in the automotive industry can detect defects with an accuracy with 99.5%

pharma

PHARMA

Capping, peel off, black particle, broken tablet- name it, DeepInspect can detect it with 99.5%+ accuracy

Consumer goods

Consumer goods

Seamlessly identify surface defects even at high speed environments of 1000+ ppm

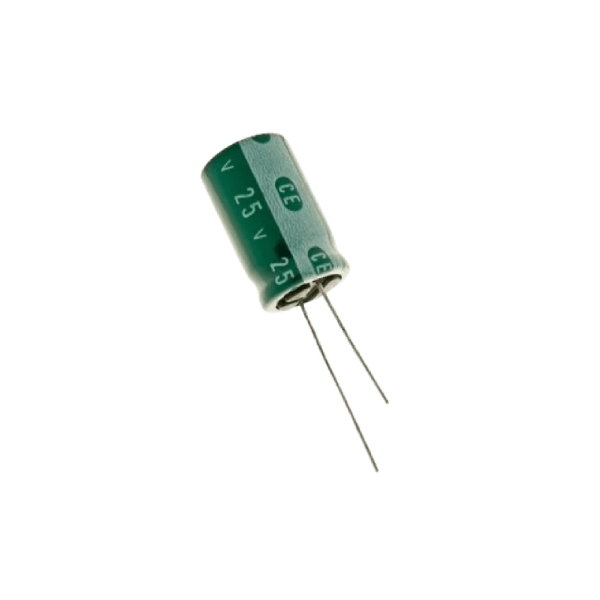

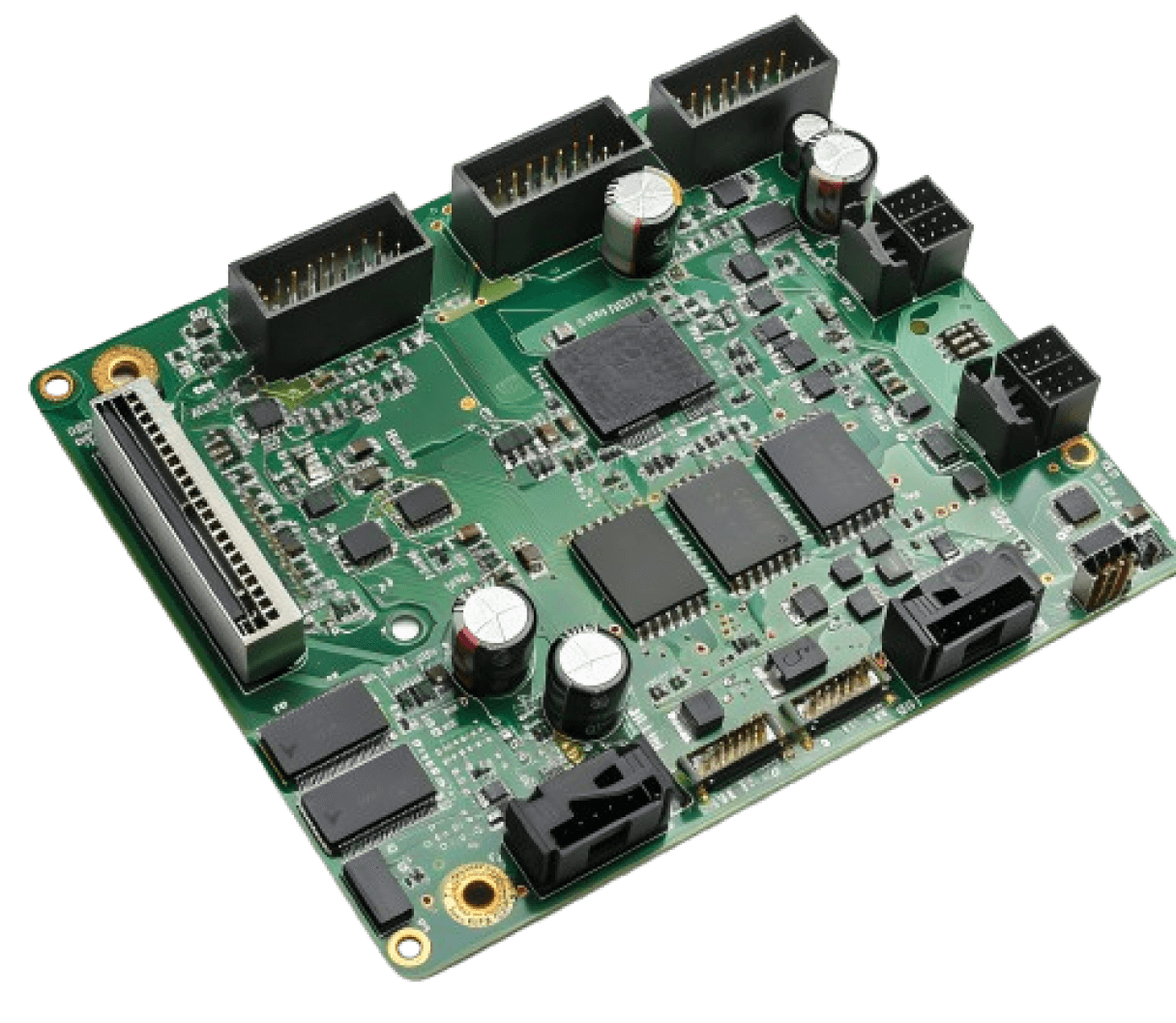

Electronics

Electronics

Spot every defect with precision – from soldering defects to surface, component, and assembly defects

What Do Our Customers Say

About Us

Hindustan Unilever

“SwitchOn, Inc.’s DeepInspect solution delivered unparalleled performance, swiftly detecting defects unseen by human eyes at lightning speed. Their team's dedication, providing 24/7 assistance from trial to implementation, exceeded our expectations. ”

Diageo

SwitchOn’s AI-Powered quality inspection software, DeepInspect® ,is a good system that yields the right benefits.

Sansera

SwitchOn, Inc. exceeded our expectations. The knowledge transfer and training were thorough, ensuring a smooth installation. They perfectly fulfilled our requirements, and we achieved 100% customer satisfaction. We were searching for the right vendor, and SwitchOn, Inc. was the perfect choice

Our Investors

Backed by Top Investors of the Nation

Latest in the News

AI-powered quality inspection for precision manufacturing

AI-powered computer vision based Quality inspection platform

AI-powered computer vision based Quality inspection platform

SwitchOn enables automotive and CPG discrete manufacturing industries to ensure product quality and process continuity.

Community Voices: How SwitchOn is enabling manufacturing companies reach zero-defects

AI-based vision inspection startup SwitchOn raises $4.2 million

SwitchOn's founders on how they're helping ITC, Unilever and SKF automate quality checks on the go

Interested in Streamlining Quality Inspection Process?

Book a Free Demo