Borescope inspection Powered by DeepInspect®

Borescope Inspection Powered by DeepInspect®: Redefining Internal Quality Control in Automotive

Related Articles

Introduction

When it comes to high-precision automotive components like fuel injector rails, even a micro-level internal defect can trigger massive consequences — from engine malfunction to complete system failure. These defects often hide in places where the human eye can’t reach. This is why borescope inspection has become indispensable for automotive manufacturers.

However, traditional borescope inspection is riddled with inconsistencies. The process is time-consuming, heavily reliant on operator experience, and does not scale well in high-throughput production environments. That’s where DeepInspect®, SwitchOn’s AI-powered visual quality inspection software, brings a paradigm shift.

This blog dives deep into borescope inspection, the limitations of traditional methods, and how DeepInspect® is revamping the process with AI.

What is Borescope?

Borescope is an essential tool in the modern production lines for ensuring quality without dismantling or destroying the part. This tool features a long, flexible tube with a tiny camera or lens on one end and a screen or eyepiece on the other. By inserting the borescope into engines, pipes, or equipment, they can quickly spot damage, blockages, or wear.

Technicians use a borescope to see inside hard-to-reach or hidden spaces without taking anything apart. It helps them perform inspections efficiently, saving time and avoiding unnecessary disassembly. Borescope plays a key role in maintenance and repair work. In short, the borescope acts as the eye where no eye can go.

Types of Borescopes

Rigid Borescopes

-

Structure: Straight tube with optical lenses

-

Best for: High-resolution viewing

-

Used in: Engine cylinder inspection, turbine blade checks

Flexible Borescopes

-

Structure: Flexible tube made of fiber optics

-

Best for: Accessing curved or confined paths

-

Used in: Aircraft maintenance, automotive piping

Video Borescope

-

Structure: Has a camera and light at the tip

-

Best for: high-quality digital imaging

-

Used in: Internal automotive components

Disposable Borescope

-

Structure: Single-use, lightweight

-

Best for: Sterile or one-time inspections

-

Used in: Medical or cleanroom environments

Components of a Borescope

Why is a Borescope Used in Automotive Inspection?

Modern automotive components are tightly packed, with complex internal geometries that are nearly impossible to access visually. A borescope solves this challenge by capturing high-resolution images from deep within these confined spaces—without dismantling the part. Whether it’s inside a fuel injector rail, an oil channel, or a cylinder head, the borescope’s slender, flexible design allows it to navigate through intricate pathways and deliver clear visuals of hidden surfaces.

This internal visibility helps engineers and quality teams better understand part integrity, surface finish, and overall build quality. Unlike traditional tools, borescopes provide a direct visual reference, enabling precise diagnostics during manufacturing or maintenance. As vehicles continue to evolve with tighter tolerances and advanced materials, the ability to “see inside” becomes critical. In essence, a borescope acts as the industry’s eye—bringing the inaccessible into full view and enabling smarter decisions without disrupting assembly.

While this hardware is widely used, its effectiveness is often limited by the human element — especially when inspection results rely solely on visual judgment.

Challenges with Traditional Borescope Inspection

Dependency on Operator and Rule-Based AI

Traditional borescope systems rely on human operators and rule-based AI models. These systems can only detect predefined defect types and often miss new anomalies. As a result, inspections remain inconsistent , especially when components vary in shape or finish

Low Throughput and Manual

Intervention

Even with AI assistance, traditional setups demand frequent human input—navigating internal paths, adjusting focus, and validating defect calls. This slows down the process, introduces fatigue-related errors, and limits scalability on fast-paced production lines

Lack of Adaptability and

Traceability

Conventional AI lacks the ability to learn from new defects or adapt to variations in lighting, surface texture, or geometry. These systems also fall short in providing real-time analytics, audit trails, or quality reports—making it hard to track, trace, or improve inspection outcomes over time

No Feedback Loop for Continuous Improvement

Traditional borescope systems lack the ability to learn from past inspections. There’s no mechanism to improve detection over time based on new defect patterns or component variations. This means the system stays static, unable to evolve with changing manufacturing needs

Solution: Borescope Inspection Powered by DeepInspect®

DeepInspect® is an AI-powered visual quality inspection software that helps automotive manufacturers spot internal defects in components using borescope. Components like fuel injector rails, oil galleries, and cylinder heads—parts with tight, complex interiors that are hard to access using traditional methods can be semlessly inspected with 99.5% accuracy

Here’s how it works: a borescope is inserted through an inlet port, such as the fuel inlet in a rail. As it moves through the internal pathways, it captures high-resolution images of the surfaces inside. These images are then analyzed by pre trained model in DeepInspect to detect issues like burrs, scratches, dents, missing holes, or improper machining

What makes DeepInspect stand out is how little it needs to get started—just 200 good internal images to train the AI model. Once trained, it delivers 99.5% defect detection accuracy. It doesn’t rely on fixed rules or operator judgment. Instead, it adapts to new defect types, surface variations, and lighting conditions—offering fast, consistent, and traceable inspection without the guesswork.

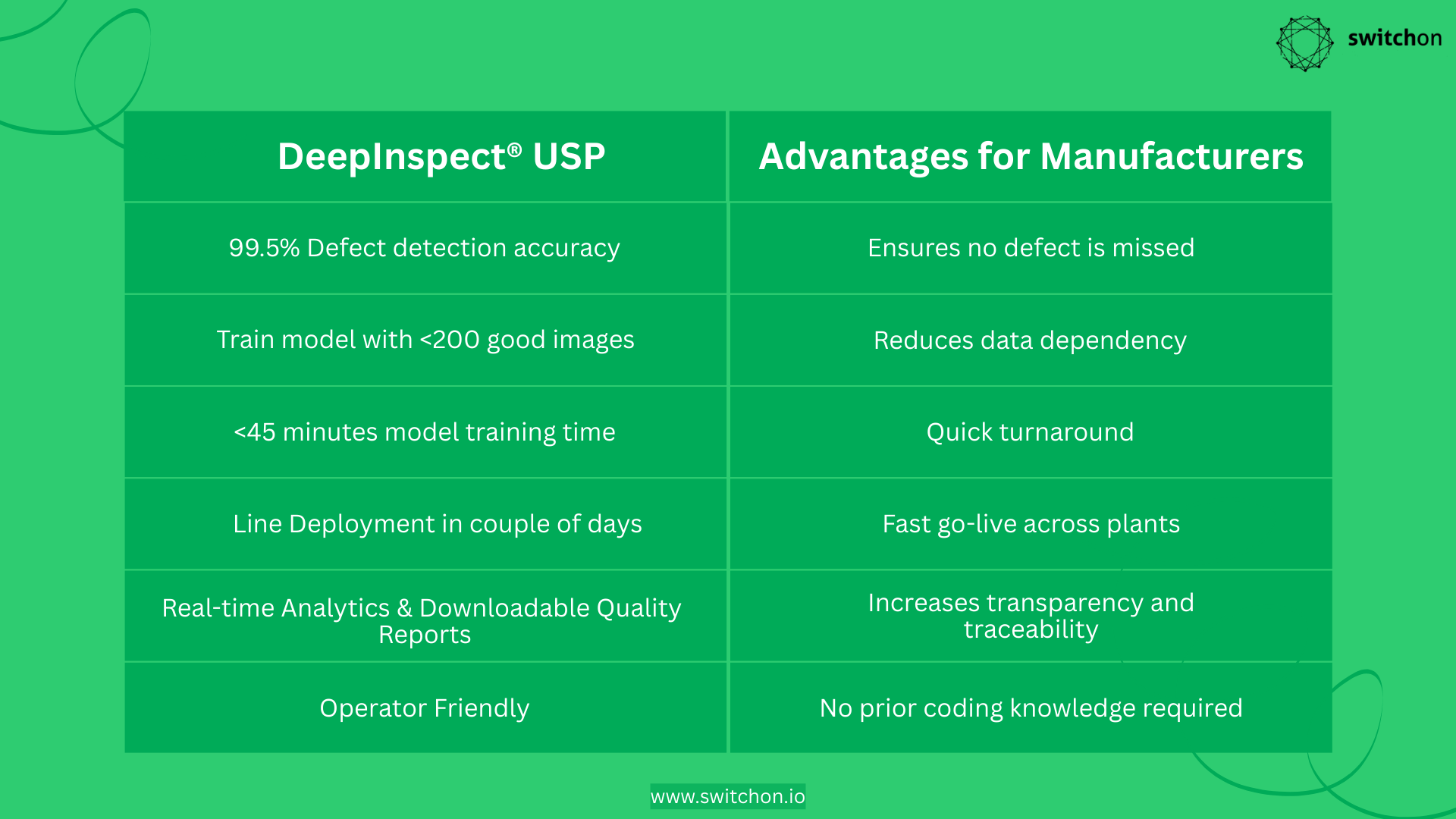

Advantages of DeepInspect® in Borescope Inspection

Conclusion

Internal defect detection no longer needs to be slow, manual, or error-prone. With DeepInspect® powering borescope inspections, automotive manufacturers can unlock a new level of quality control that’s faster, smarter, and more scalable. Whether it’s fuel injector rails or engine housings, DeepInspect adapts to the component, the workflow, and the people using it.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.