AI- POWERED PLASTIC BOTTLE INSPECTION

DeepInspect- Visual Inspection Software for Plastic Bottles powered by AI

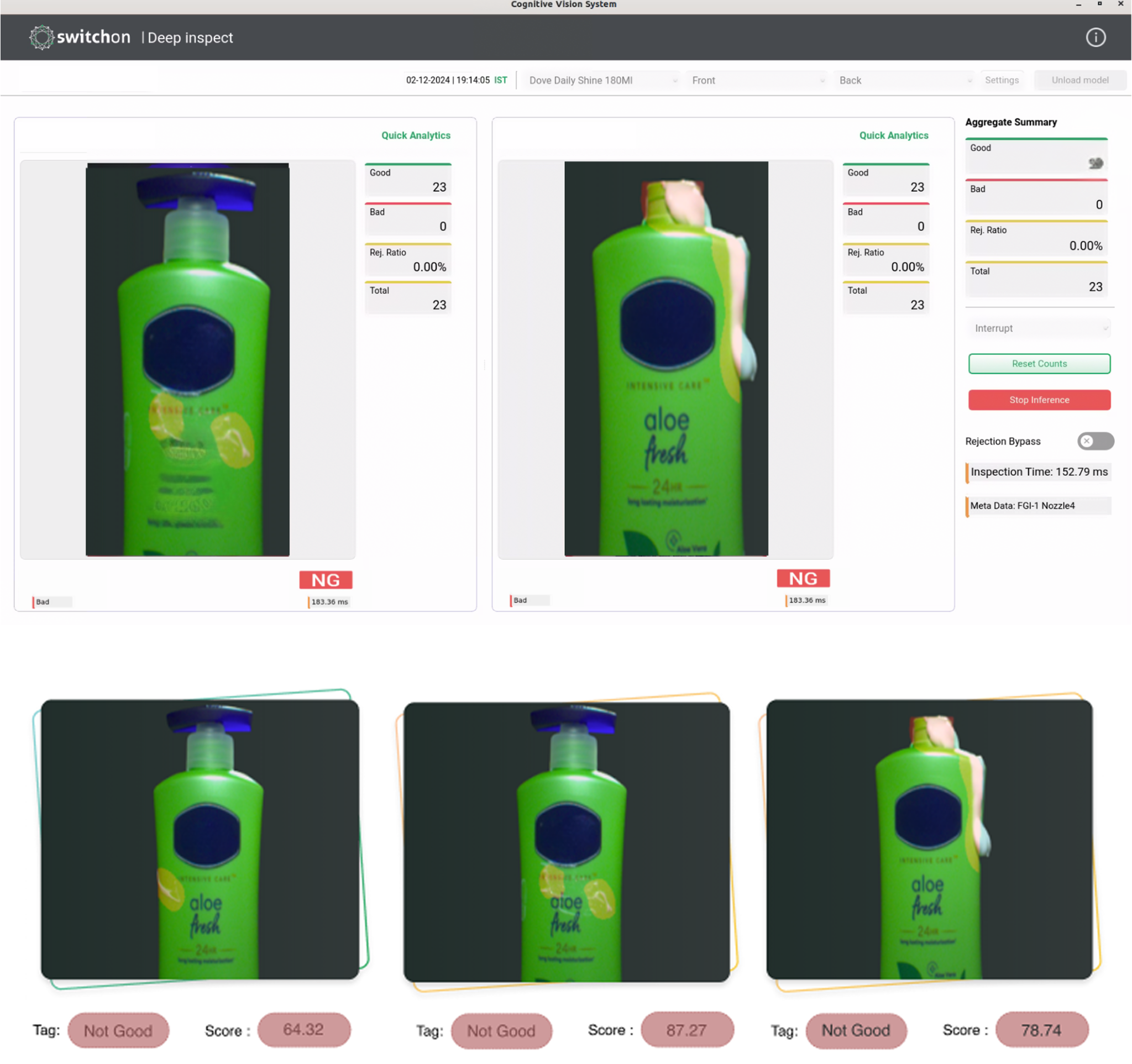

Ensure perfection in every plastic bottle with our cutting-edge AI-powered visual inspection software, DeepInspect. Designed for machine vision for plastic bottles, our system provides automated quality control by detecting defects like cracks, fill-level inconsistencies, scratches, and cap misalignments in real-time. Leveraging vision inspection systems for bottles, this advanced solution uses computer vision and machine learning to identify quality issues early, helping manufacturers boost accuracy, efficiency, and product consistency. Our technology seamlessly integrates into your production line and adapts to various bottle shapes, sizes, and materials. Whether you’re producing food-grade bottles, pharmaceuticals, or cosmetic containers, our software delivers reliable, high-speed inspection that ensures compliance and brand integrity. With tailored food-grade bottle inspection solutions, you can reduce waste and enhance consumer satisfaction without slowing down your workflow. Empower your packaging process with smart, scalable, and cost-effective automated quality control for plastic bottles.

APPLICATION

Achieve flawless packaging with precise bottle label artwork defect detection

Eliminate packaging errors with precise detection of printed label alignment issues

Enhance packaging accuracy with advanced OCR for bottle labeling inspecton

Ensure product integrity with precise cap misalignment and missing cap inspection

Impact

AI-powered bottle inspection software, DeepInspect brings automated quality control to plastic bottles, enabling real-time AI defect detection. It revolutionizes the AI in packaging industry, improving accuracy, efficiency, and reducing waste

Detect all kind of defects with 99.5% Accuracy

Plastic bottle defects

Bottle cap defects

Label & artwork defects

OCV/OCR

AI-Based Plastic Bottle Inspection System for High-Speed Defect Detection

DeepInspect® - Best Machine Vision Plastic Bottle Inspection System for Quality Control

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

Foreign Particle Detection in Plastic Bottles Using Vision AI Inspection

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in Plastic & HDPE bottle defect detection software?

Book a free demo!

Inquiry Form

Common defects include dents, deformation, flash, short molding, sink marks, scratches, black spots, contamination, and neck finish defects.

HDPE bottle inspection is done using automated vision systems that detect surface, neck, and shape-related defects in real time without slowing production.

Because even small neck finish defects can cause leakage, improper sealing, cap misfit, and rejection at the filling stage.

Yes, AI-powered visual inspection can detect black spots, stains, foreign particles, and embedded contamination with high consistency.

Manual inspection is operator-dependent and inconsistent, while AI inspection ensures repeatable accuracy and stable defect detection 24/7.

DeepInspect® is one of the best Vision AI inspection software platforms for plastic and HDPE bottle defect detection at scale.

DeepInspect® delivers up to 99.5% defect detection accuracy, helping prevent defect leakage and reduce customer complaints.

DeepInspect® can be trained in under 45 minutes, enabling quick deployment for new bottle designs and defect variations.

DeepInspect® requires less than 200 good images for training, making it easy to implement even in fast-changing production setups.

DeepInspect® maintains less than 0.5% false positives, reducing unnecessary rejection while ensuring strict quality control.