AI- POWERED TOOTH BRUSH INSPECTION

DeepInspect- Machine vision tooth brush quality control software

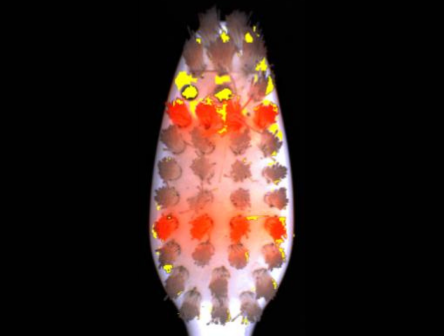

AI-powered tooth brush quality inspection using DeepInspect revolutionizes the way toothbrushes are evaluated in manufacturing. Leveraging advanced machine vision and AI inspection systems, DeepInspect automates the detection of tooth brush defects, ensuring superior product quality. With its ability to analyze flowering defects, less nylon defects,missing tuft, etc. the tooth brush quality inspection software offers unmatched precision compared to traditional AI inspection methods. The integration of deep learning enables accurate identification of even the smallest defects, such as bristle misalignment or handle cracks. The use of automated tooth brush inspection streamlines the production process, reduces human error, and ensures that every toothbrush meets FDA toothbrush standards and ISO toothbrush inspection guidelines. DeepInspect not only enhances product quality but also improves efficiency, reducing production costs and ensuring compliance with industry regulations. DeepInspect represents the future of toothbrush quality control, offering reliable, scalable, and efficient defect detection.

APPLICATION

Ensure minimal nylon defects with real-time AI-powered visual inspection

Identifies missing tufts accurately, ensuring proper placement and uniformity

Detects flowering defects, preventing subpar products from reaching customers

Spots raised anchor wire defects, ensuring consistent product durability

Impact

DeepInspect revolutionizes toothbrush quality inspection by automating defect detection, ensuring precise bristle alignment, nylon defects etc. and compliance with safety standards. It enhances efficiency, reduces human error, and improves overall product quality.

Detect all kind of defects with 99.5% Accuracy

Less Nylon

Missing Tuft

Flowering Defect

Raised Anchor Wire

Interested in Streamlining Tooth Brush Quality Inspection Process?

Drop us a line or shoot us an email

Inquiry Form

DeepInspect offers 99.5% accuracy with less than 0.5% false positive rates, making it a reliable solution for automated quality control of tooth brushes.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection in tooth brushes.

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection systems for tooth brushes.

A line demo for DeepInspect’s tooth brush inspection system can be conducted within a day, showcasing its fast implementation and ease of use.