Powertrain Quality Control | Automotive

DeepInspect is a cutting-edge AI-powered solution for powertrain quality inspection, offering unmatched accuracy in identifying defects across engine and transmission systems. By automating visual inspection, it ensures every powertrain component complies with the highest OEM quality standards. With 99.5% detection accuracy and less than 0.5% false positives, DeepInspect enables comprehensive and reliable powertrain quality testing. It integrates seamlessly into existing quality management systems, supports real-time analytics, and is deployable within days—accelerating ROI. DeepInspect replaces manual and traditional AI inspection with a scalable, automated solution that boosts consistency and efficiency. Trusted by top automotive OEMs and tier-1 suppliers, it’s a proven tool for driving lean manufacturing, reducing rework, and ensuring zero-defect delivery across complex assembly lines.

APPLICATION

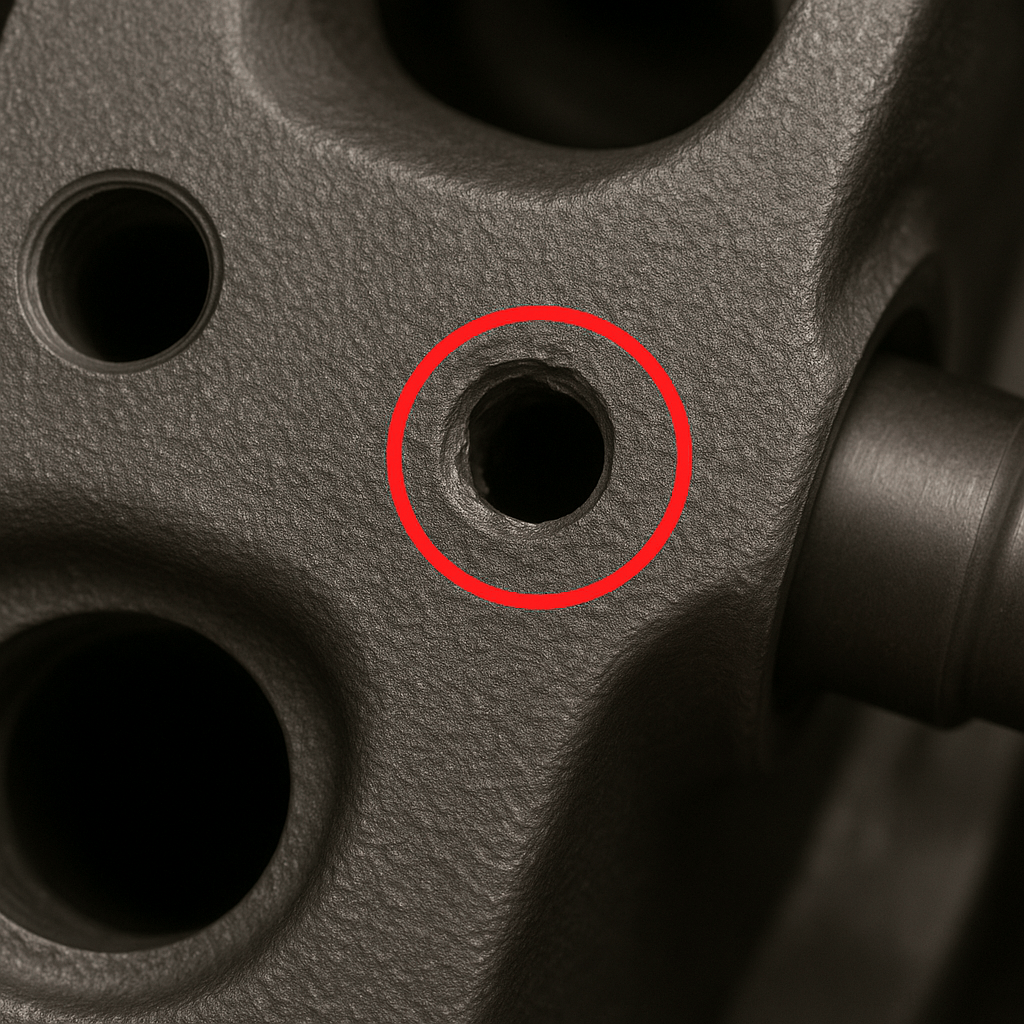

Detects scratches, cracks, dents, burrs, scuffs and surface defects in real-time

Identifies excess material, warpage, and dimensional inconsistencies with precision

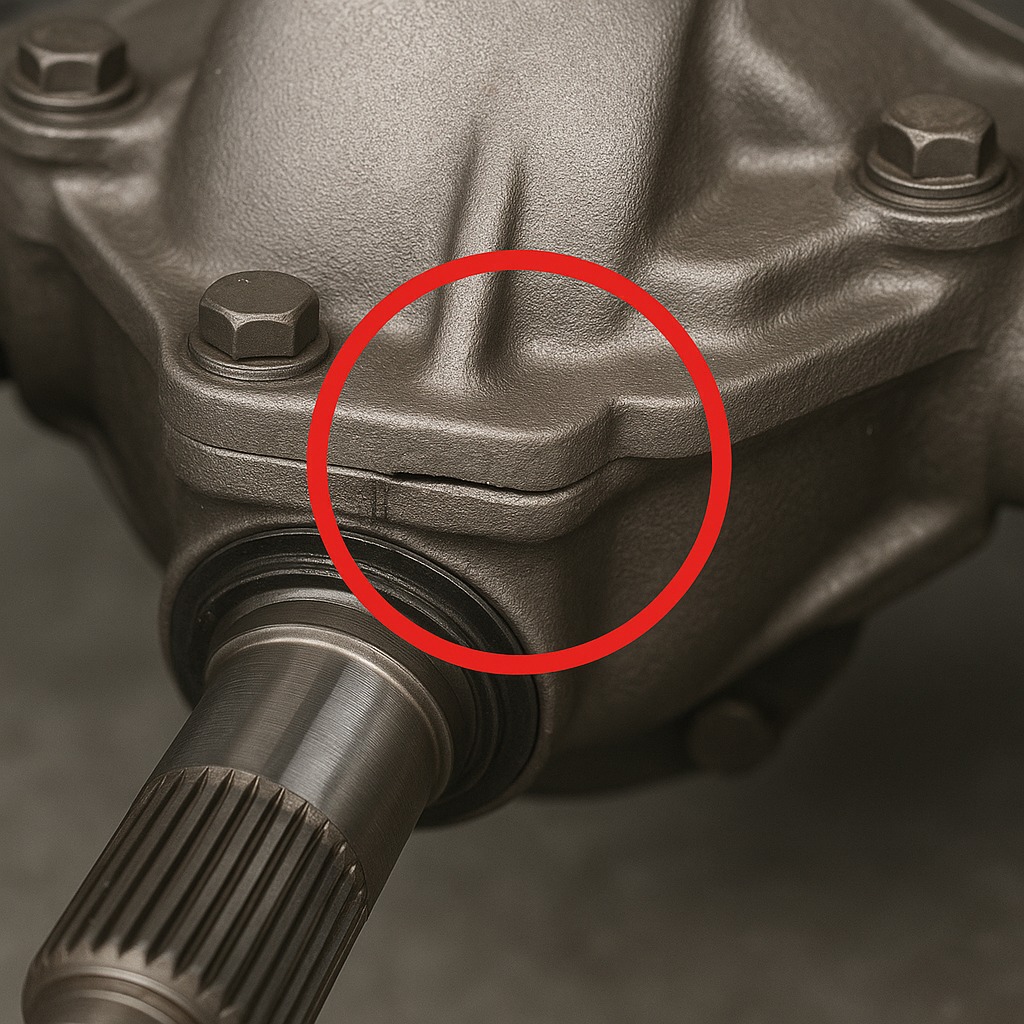

Identifies assembly defects like missing parts, loose fits, and incorrect assemblies instantly

Verifies part numbers, VIN codes, and other engraved characters with 99.5% accuracy

Impact

DeepInspect empowers manufacturers with AI-driven powertrain quality inspection, enabling real-time detection of engine and transmission defects with 99.5% accuracy, seamless integration into quality systems, reduced manual effort, and rapid deployment for consistent, scalable, and zero-defect production across automotive lines.

Powertrain Quality Inspection with 99.5% Accuracy

Surface Defects

Dimensional Inaccuracies

OCV/ OCR

Improper Fitment

Interested in Streamlining Powertrain quality control ?

Drop us a line or shoot us an email

Inquiry Form

Powertrain quality inspection ensures engine, transmission, and axle components meet OEM standards, reducing failure risks and warranty claims

AI-powered powertrain inspection system DeepInspect detect defects in real time with 99.5% accuracy, minimizing false positives and manual rework.

Typical defects include cracks, misalignments, surface wear, dimensional variations, improper assembly across engine and transmission components

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for defect detection

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection system

A line demo for DeepInspect system can be conducted within a day, showcasing its fast implementation and ease of use