360° Spark Plug Inspection Powered by DeepInspect

Revolutionizing 360° Spark Plug Inspection with Single Camera System

Related Articles

The Spark Plug – A Small Component with a Critical Role

Spark plugs are among the most vital components in an internal combustion engine. They ignite the air-fuel mixture that powers the engine, ensuring smooth startup, optimal combustion, and fuel efficiency. Given their essential function and high-speed operation under intense pressure and heat, maintaining consistent spark plug quality is non-negotiable. Any surface defect, no matter how small, can lead to misfires, reduced engine performance, or even catastrophic failure. That’s why visual inspection of spark plugs is a crucial quality control step in modern manufacturing.

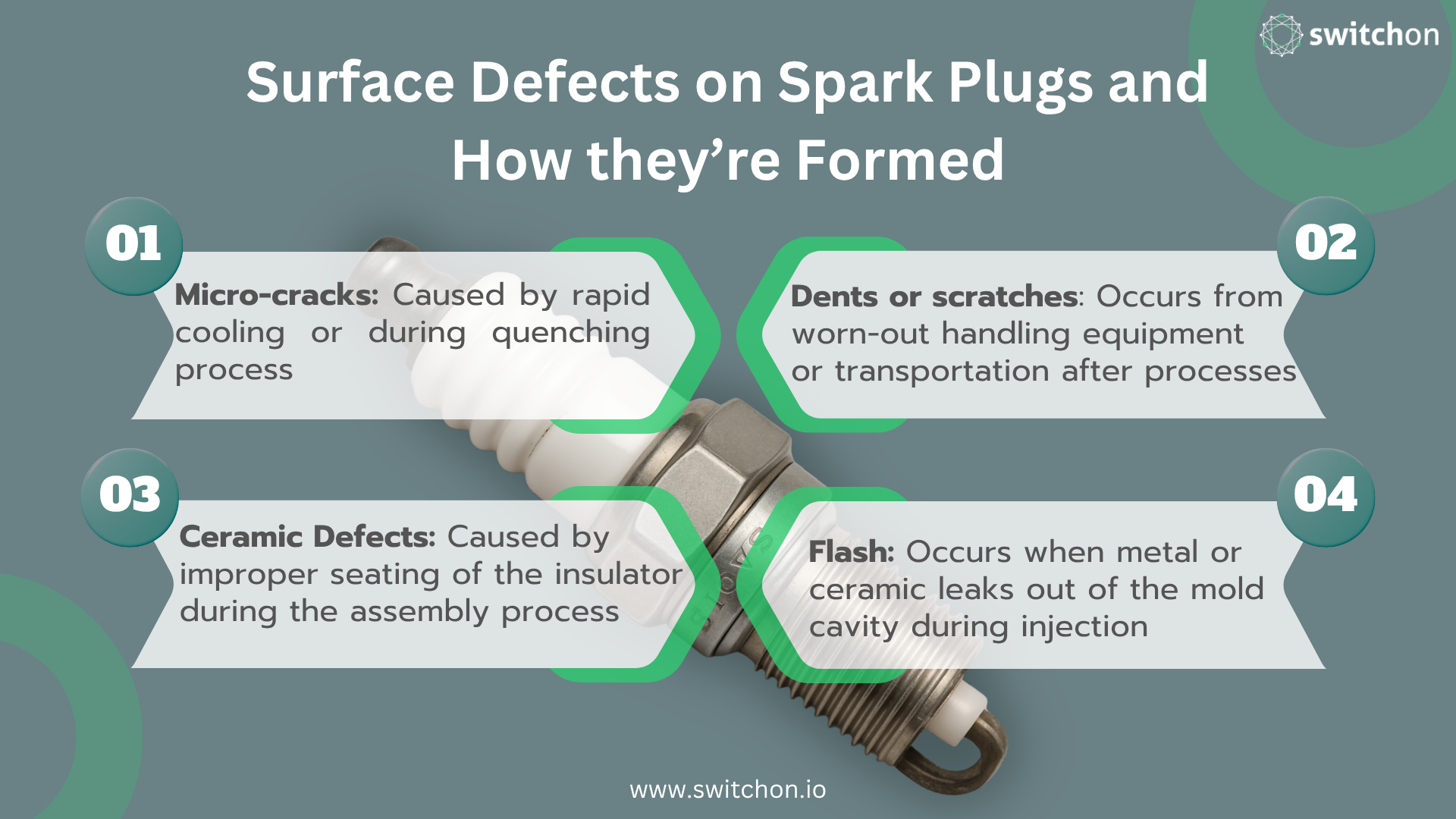

Surface Defects on Spark Plugs and How They’re Formed?

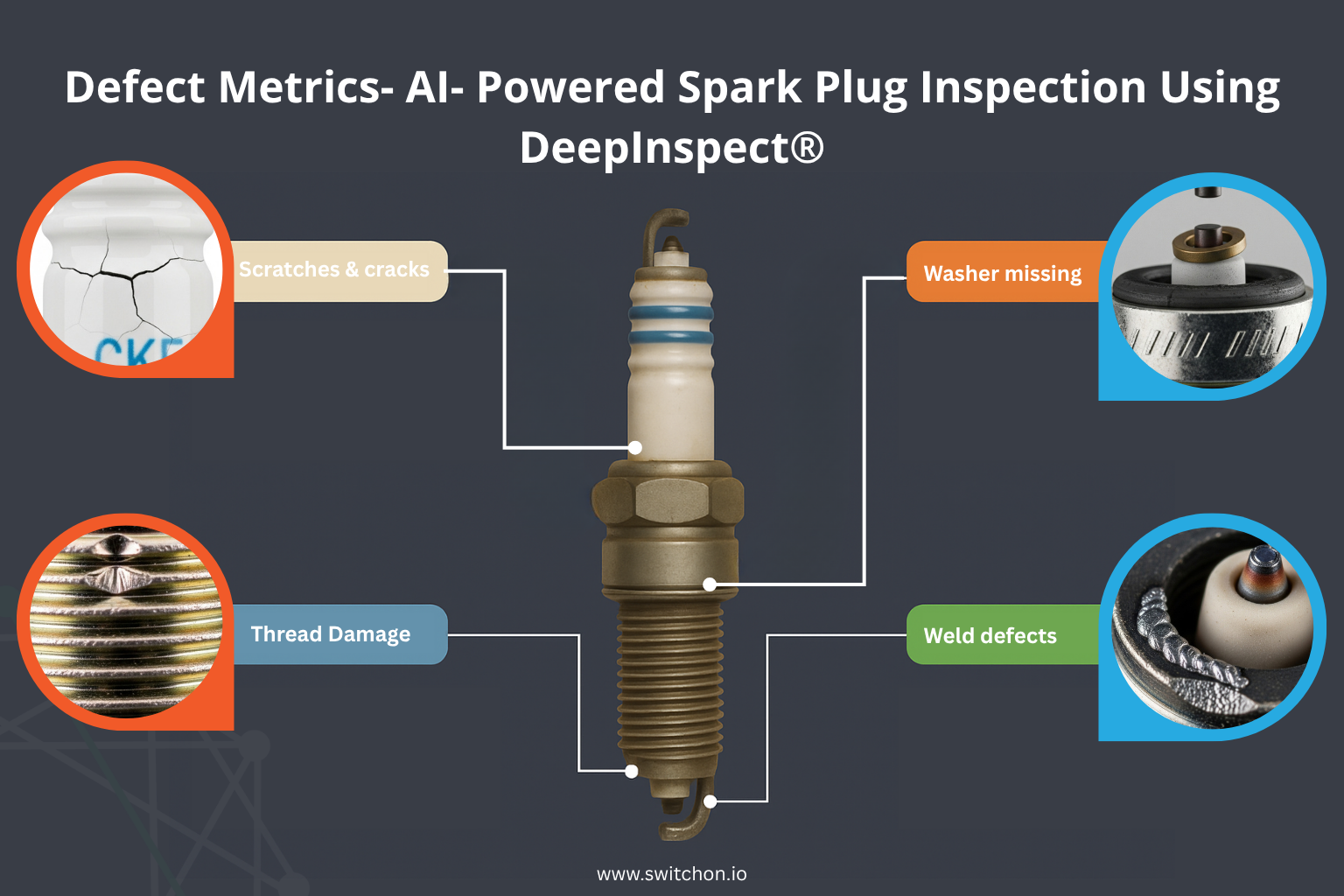

During the high-speed manufacturing of spark plugs, several surface defects can occur due to a mix of thermal, mechanical, and material-related factors. Here are few of the most common spark plug defects — and what causes them:

These defects can be difficult to detect manually— making AI powered spark plug visual inspection essential for reliable quality control. But traditional AI inspection of Spark Plug comes with a lot of limitations.

Why Traditional AI Spark Plug Inspection Systems Mostly Fail?

While AI Spark Plug inspection software systems promise automation and speed, traditional models often rely on multi-camera setups or fixed-angle vision systems. These methods struggle with:

- Incomplete coverage — blind spots leave defects undetected

- Difficulty in inspecting round and reflective surfaces like ceramic bodies

- High false positives due to inconsistent lighting or poor model generalization

- Complex calibration and high cost due to multiple cameras and hardware components

For high-speed spark plug production lines, these shortcomings translate to missed defects, increased rework, and productivity losses.

The Solution: AI Powered 360° Spark Plug Inspection Using DeepInspect® Single Camera System

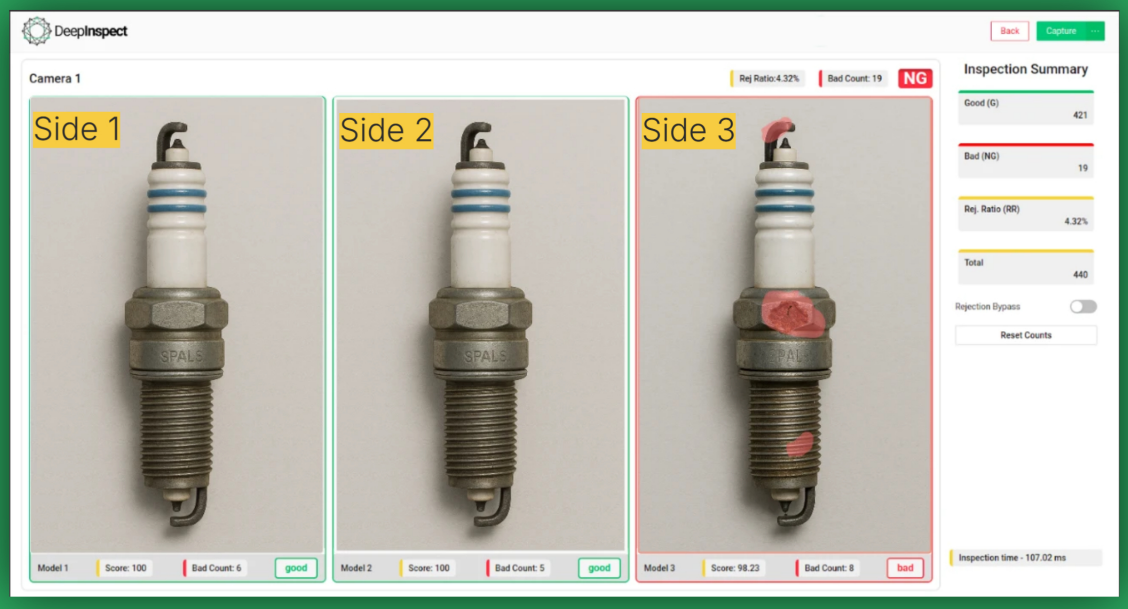

DeepInspect® is an AI-powered spark plug inspection software that enables manufacturers to perform full 360° surface inspection using just a single-camera system.

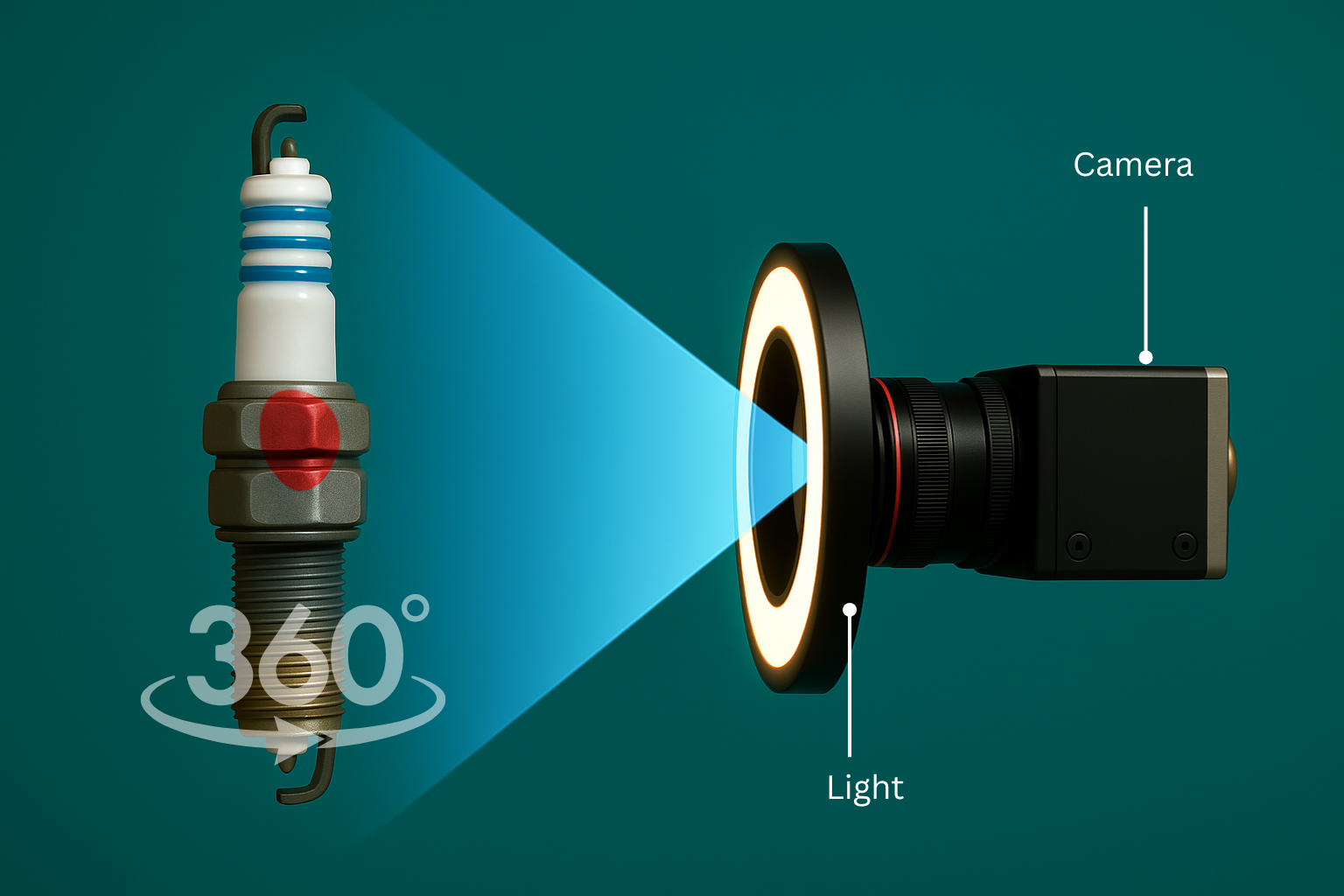

The Setup

Unlike traditional multi-camera setups, DeepInspect® combines intelligent vision with controlled spark plug rotation to capture a complete, high-resolution view of the component. With less than 200 good images and just 45 minutes of training time, the system accurately detects subtle defects like micro-cracks, dents, burrs, and ceramic misalignments — all with an industry-leading 99.5% accuracy.

DeepInspect® Software

360° Spark Plug Inspection Using DeepInspect Ensures:

- High-resolution coverage of all sides, including the ceramic insulator and electrode region using single camera system

- Robust defect detection across variations in lighting, geometry, and orientation

- Compact setup with reduced hardware complexity and cost

- 99.5% defect detection accuracy

- <0.5% false positive rate

- Cost effective inspection

Why DeepInspect®?

- Requires fewer than 200 good images for AI model training

- Model training completes in under 45 minutes

- True 360-degree inspection using just single camera system system

- False positive rate below 0.1%, reducing unnecessary manual checks

- Optimized for fast deployment

- Minimizes inspection infrastructure complexity and costs

- Delivers high-accuracy results suitable for high-throughput lines

Conclusion

As demand for performance and reliability grows, so does the need for robust automated spark plug inspection systems. DeepInspect is transforming how manufacturers ensure spark plug quality — reducing defects, minimizing customer complaints, reducing costs and enhancing operational efficiency.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.