AI- POWERED BOTTLE CAP INSPECTION

DeepInspect®-AI Powered Bottle Cap Inspection System

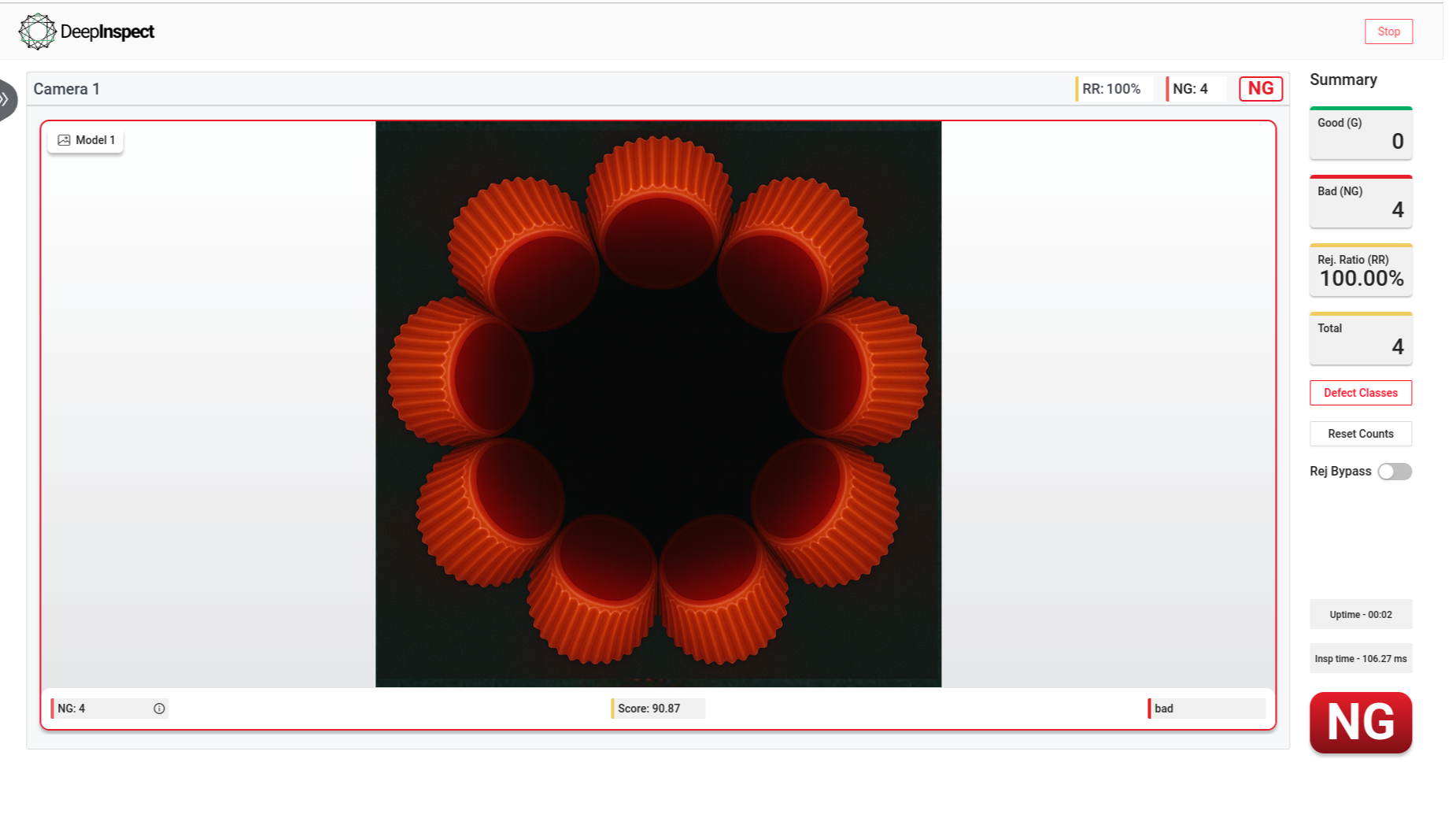

Bottle cap inspection using DeepInspect, camera-based inspection cap software, ensures precise and reliable detection of food-grade cap defects such as missing wads, scratches, seal integrity issues, and surface damages. Powered by advanced vision optics and AI algorithms, the system performs bottle cap inspection using just a 2-camera setup, enabling complete 360-degree cap inspection while significantly reducing hardware costs. DeepInspect can be used to perform inline cap inspection systems across industries like FMCG, pharmaceutical, and beverage packaging lines. Its a powerful FMCG packaging inspection software that adapts to different cap types—flat, flip-top, or crown—with minimal training data, delivering 99.5% accuracy. The result is a cost-effective cap inspection system that eliminates manual errors, ensures cap sealing quality, and drives consistent product output. DeepInspect empowers bottle cap manufacturers with scalable, real-time automated cap inspection to ensure every closure meets the highest quality standards.

APPLICATION

Vision inspection of surface defect detection on caps like dents and deformations

High-speed visual quality inspection of grease, black spots, etc. on caps

Quality inspection of wad presence/absence, sealing integrity etc.

Bottle capping quality control by identifying scratches on caps

Impact

DeepInspect® revolutionizes inspection for beverage closures by seamlessly detecting missing wads, seal integrity, dents, deformation. scratches, foreign particles, etc.

AI bottle Cap Inspection with 99.5% Accuracy

Cap Dents

Greese & Black Spots

Wad Presence/ Absence

Cap Scratches

360° Camera-based Bottle Cap Inspection Using Two Camera System

Interested in Streamlining Bottle Cap Quality Inspection Process?

Drop us a line or shoot us an email

Inquiry Form

Bottle cap inspection is the process of detecting defects like missing wads, scratches, seal integrity issues, and improper closure. Ensuring cap quality prevents leakage, contamination, and customer complaints.

DeepInspect uses advanced vision optics and AI to deliver automated cap inspection with a compact 2-camera system, enabling 360-degree cap inspection in real-time with over 99.5% accuracy.

DeepInspect offers 99.5% accuracy with less than 0.5% false positive rates, making it a reliable solution for automated quality control.

DeepInspect detects even the minute surface defects on bottle caps like dents, missing wads, incorrect cap sealing, orientation issues, cracks, black spots, grease on caps, etc.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection systems.

A line demo for DeepInspect’s cap inspection system can be conducted within a day