Vision inspection system for label compliance and traceability

DeepInspect®- AI-powered label quality inspection software for label compliance and traceability- Pharma, FMCG, Automotive & Electronics

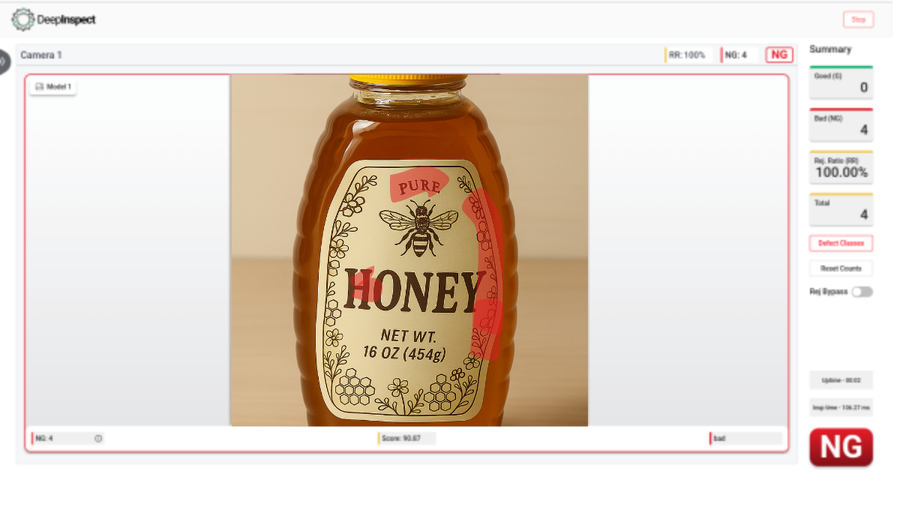

Our AI-powered vision inspection system — DeepInspect® — redefines label quality inspection and automated label verification with an impressive 99.5% accuracy across high-speed pharma, FMCG, and packaging lines. This intelligent machine vision label inspection system performs real-time label defect detection, print quality verification, OCR/OCV inspection, and barcode or data-matrix inspection to guarantee zero-defect packaging. DeepInspect® identifies bubbles, wrinkles, misalignment, missing labels, and text or color deviations, ensuring full label compliance and traceability.

Powered by AI-based deep learning, the inline vision inspection system continuously adapts to evolving defect patterns with minimal training data. Ideal for smart packaging automation, DeepInspect® helps manufacturers enhance label accuracy, reduce waste, eliminate rework, and maintain consistent brand integrity — achieving real-time vision inspection excellence and zero-defect manufacturing for every product, every time

APPLICATION

Detect skewed or improperly placed labels precisely using DeepInspect®

Identify label wrinkles and bubbles that distort surface appearance and readability

Detect missing or double-applied labels to ensure complete packaging accuracy

Verify printed text and codes through precise OCR/OCV inspection for label compliance

Impact

DeepInspect® revolutionizes label inspection with advanced machine vision technology that ensures accurate label presence and absence detection, superior label quality control, and flawless inspection for FMCG, Pharma, Automotive, and Electronics product labels — empowering manufacturers to achieve zero-defect packaging with unmatched precision and reliability

Vision inspection system for container label quality with 99.5% Accuracy

Torn Label Defect

Bubble Label Defect

Label Color Variation

Label Print Errors

Skewed Label

Overlapping Labels

Wrinkles on Labels

Label Contamination

machine vision label inspection for zero-defect packaging

Interested in Packaging & Label defect detection software?

Book a free demo!

Inquiry Form

DeepInspect® is an AI-powered machine vision label inspection system designed for real-time label quality control in high-speed manufacturing lines. It ensures 99.5% accuracy in detecting label defects such as misalignment, wrinkles, missing labels, and print errors.

DeepInspect® uses AI deep learning models and high-resolution industrial cameras to inspect every product in real time. The system detects surface, print, and barcode defects, verifies OCR/OCV text, and ensures that every label is perfectly placed and readable before packaging.

DeepInspect® is widely used in the pharmaceutical, FMCG, cosmetics, beverage, and electronics industries for machine vision-based label quality control. It helps eliminate manual inspection errors and ensures compliance with regulatory printing and packaging standards.

AI systems like DeepInspect® use deep learning models trained on fewer than 200 good images to identify defects in milliseconds. The system inspects 1,000+ parts per minute with 99.5% accuracy, providing actionable data through real-time dashboards.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect® requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect® uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

A line demo for DeepInspect®’s cap inspection system can be conducted within a day