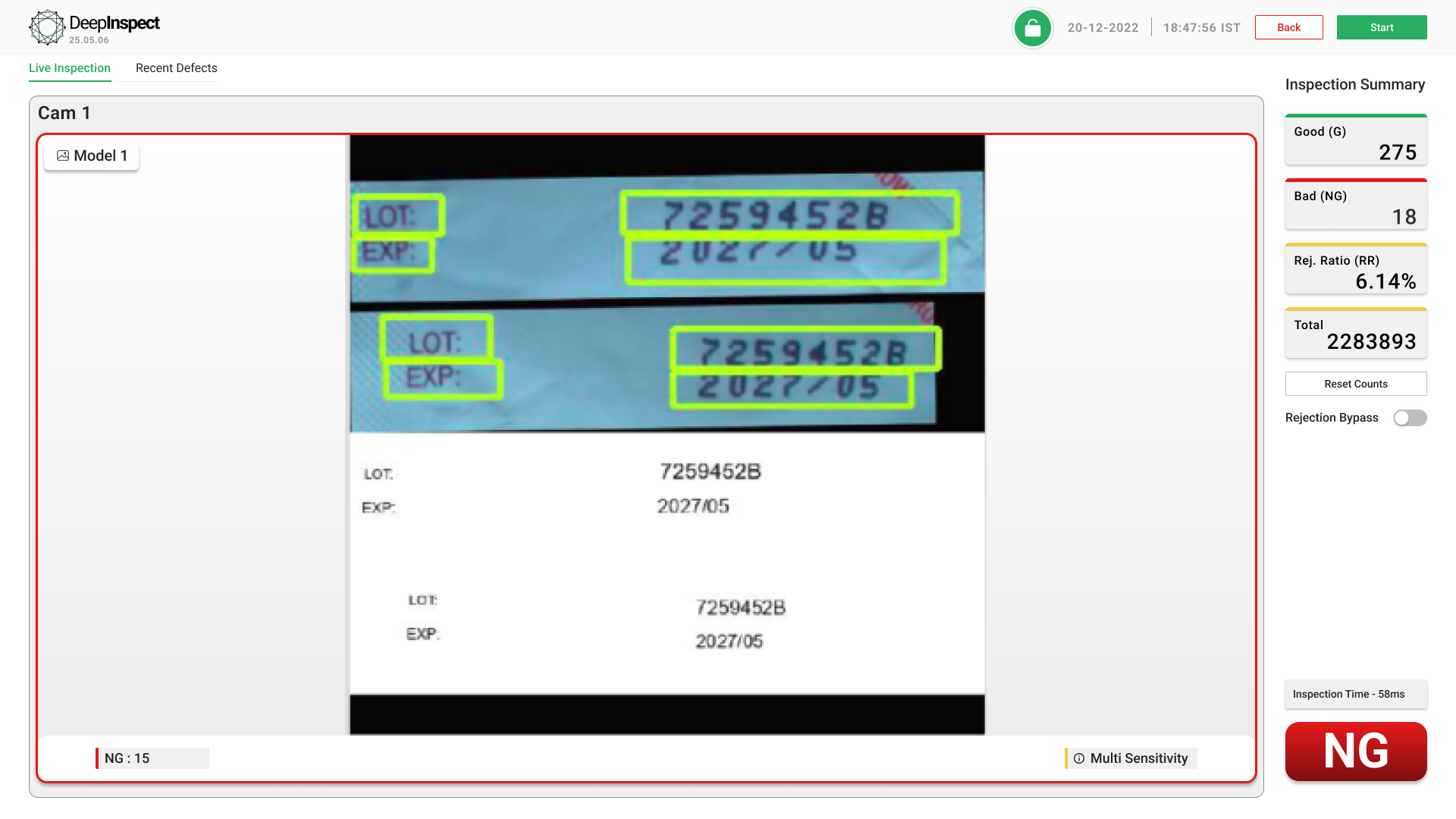

Batch code, expiry date reading vision system for manufacturing

DeepInspect®- AI-powered lot code and expiration date reading and verification software with ERP and MES integration for Pharmaceutical, Electronics, Automotive & FMCG packaging

AI-powered lot code, expiration date, and batch code inspection using DeepInspect® ensures every printed code is clear, accurate, and compliant. Powered by advanced OCR and OCV algorithms, DeepInspect® detects critical print defects such as missing or unreadable codes, faded or smudged prints, misalignment, broken or merged characters, and incorrect date formats. Designed for high-speed packaging lines across pharma, FMCG, automotive, and electronics industries, it recognises and verifies lot code readability, expiration date accuracy, batch code consistency, etc., with 99.5% accuracy. DeepInspect® empowers manufacturers to achieve zero-defect printing, reduce product recalls, and ensure complete traceability and compliance across global production lines.

Its AI-driven vision engine adapts to diverse packaging materials — including plastic, metal, paper, and glass — ensuring accurate inspection even under variable lighting and surface conditions. DeepInspect® offers effortless integration with ERP and MES systems, enabling automatic data synchronization for lot codes, production batches, and rejection logs.

USECASE

Effortlessly integrates with your existing MES and ERP systems, enabling end-to-end visibility

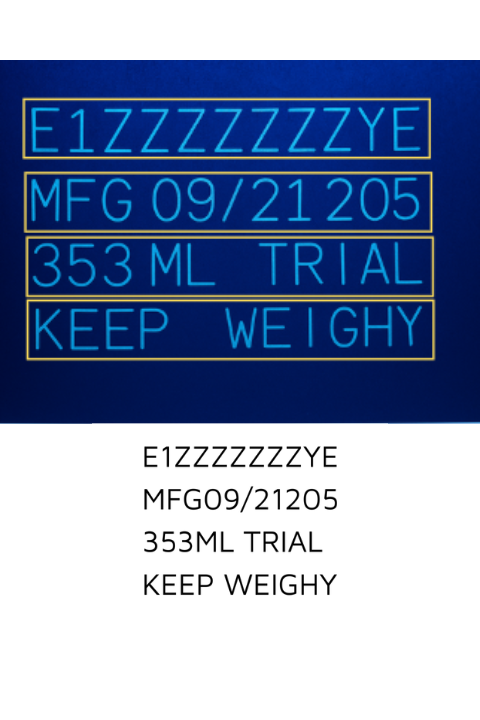

Accurately reads and verifies even complex special characters — @ # $ % ^ & * — with high precision

Character and code legibility issues, such as broken or distorted characters, can be swiftly detected

Data errors, like missing, incorrect, or mismatched codes, can be effectively detected and flagged

Impact

AI-powered lot code and expiration date inspection ensures precise date–lot code verification, expiration date code reading, lot code print inspection, etc., enabling accurate batch code and expiration date inspection across global manufacturing lines for zero-defect, high-speed quality assurance

Type of Defects

Unreadable Code

Dust/ Oil Presence

Skewed Print Defect

Ink Bleed Defect

Uneven Contrast Defect

Faded Print Defect

Broken Character

Uneven Character Gaps

DeepInspect® reads and verifies special characters and any font with 99.5% accuracy

Expiration date code reading and verifying software for Pharma, FMCG, Automotive & Electronics Manufacturers

Seamless integration with ERP and MES systems

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

Verify any code on any surface -Plastic, paper, metal, glass, etc.

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in packaging expiry date and lot code readability inspection software?

Book a free demo!

Inquiry Form

AI-powered lot code inspection automatically detects, reads, and verifies printed lot codes, expiration dates, and batch codes using OCR and OCV technology. It ensures accurate printing, correct data, and full traceability across production lines.

Lot and expiration code inspection prevents labeling errors, ensures regulatory compliance, and helps avoid product recalls. It guarantees every package carries readable and accurate production information.

DeepInspect® detects missing prints, faded or smudged ink, double prints, misaligned codes, broken characters, and incorrect date formats—ensuring every printed code is accurate and legible.

DeepInspect® uses AI-based OCR (Optical Character Recognition) and OCV (Optical Character Verification) to read and validate printed text and numbers on high-speed lines, achieving 99.5% accuracy.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect® requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect® uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

A line demo for DeepInspect®’s cap inspection system can be conducted within a day