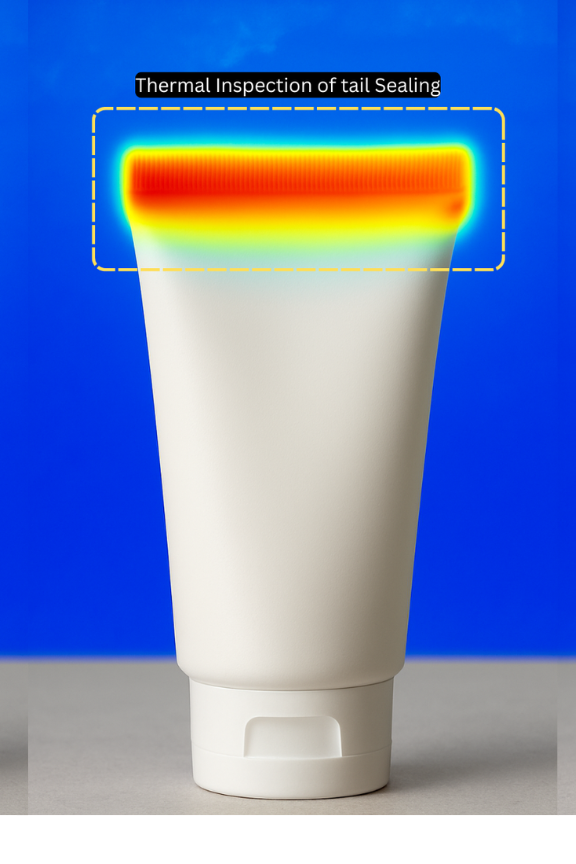

Automated Squeeze Tube Seal Inspection using Thermal Camera for FMCG Packaging Lines

DeepInspect® – AI-driven Squeeze Tube Seal Inspection Software Built for FMCG Packaging

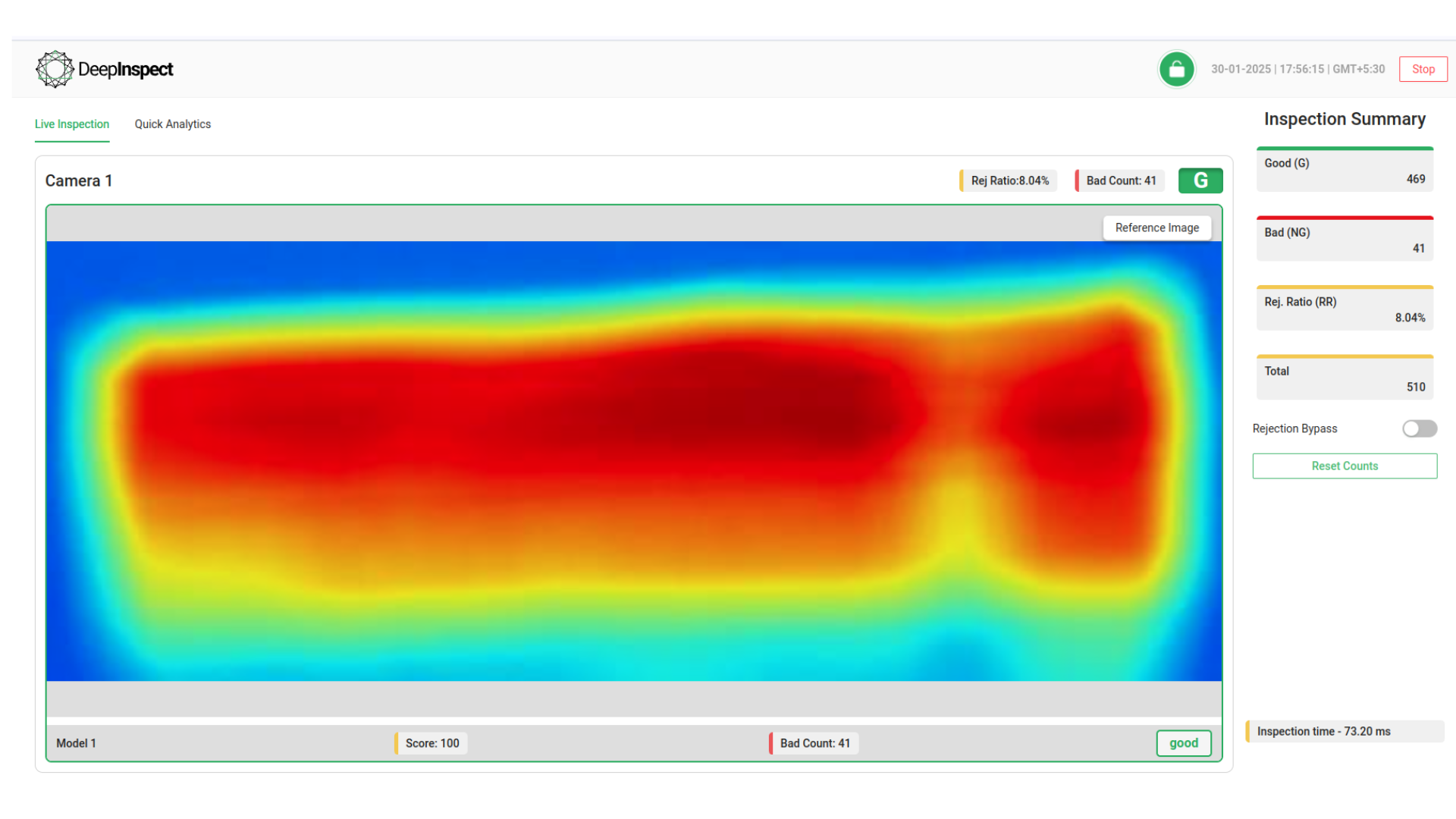

DeepInspect® delivers cutting-edge Squeeze Tube Seal Inspection for FMCG brands with its advanced AI vision system and thermal camera–enabled inspection technology. Built for high-speed packaging lines, the system performs real-time tube sealing defect detection, identifying issues such as under-sealing, over-sealing, burn marks, wrinkles, contamination, air entrapment, and seal misalignment with exceptional precision.

Using deep learning and thermal imaging, DeepInspect® adapts to different tube materials, colors, sealing temperatures, and production speeds—making it one of the most reliable automated tube inspection systems available. Every tube is inspected at full line speed, ensuring 100% coverage without manual intervention.

With seamless MES/ERP integration, manufacturers gain powerful analytics, defect trends, and actionable insights to enhance process capability and reduce customer complaints. DeepInspect® sets a new benchmark in FMCG packaging inspection, enabling brands to achieve zero-defect packaging through unmatched speed, accuracy, and reliability.

USECASE

Provides rapid setup and exceptional repeatability, ensuring a highly efficient and reliable solution

Detects cut foils, underheated seals, burnouts, and missing seals effectively

Precisely processes images, ensuring consistent results that improve inspection efficiency

Achieves 99.5% defect detection accuracy with under 1% false positives

Impact

Using DeepInspect for squeeze tube seal inspection transforms packaging quality. Traditional vision systems rely on visible changes and rigid thermal rules, often missing complex or hidden sealing defects. DeepInspect’s AI-driven thermal camera vision system overcomes these limits, detecting subtle issues with superior accuracy and ensuring consistent, high-quality FMCG packaging

AI-Powered squeeze tube seal inspection for multiple tube sealing defects

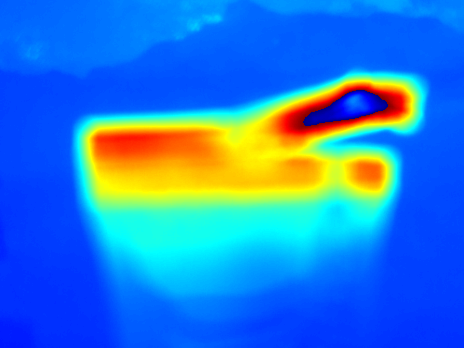

Squeeze Tube Seal Damage

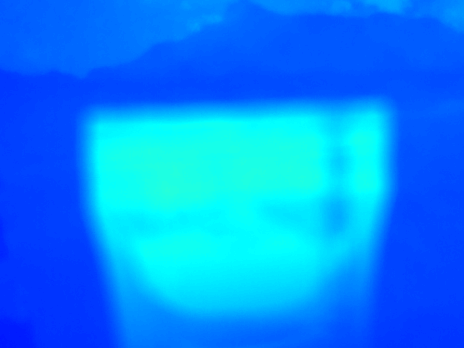

No Seal on Squeeze Tube

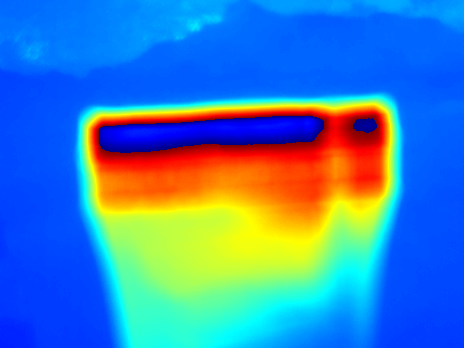

Squeeze Tube Half Seal

Squeeze Tube Improper Seal

High-Repeatability cosmetic tube seal inspection for premium packaging quality

The best software for automated cosmetic tube seal inspection on high-speed lines.

Traditional AI systems miss subtle seal defects—DeepInspect® catches them instantly with AI + Thermal imaging

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

Tube deformation defect detection with under 200 good training images

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in over-sealing / under-sealing defect detection software?

Book a free demo!

Inquiry Form

Squeeze Tube Seal Inspection is a vision-based process that detects sealing defects such as under-sealing, burnouts, wrinkles, and misalignment. It ensures zero-defect quality for FMCG, cosmetic, and pharma tubes.

AI-powered Squeeze Tube Seal Inspection uses deep learning and computer vision models to detect complex sealing defects automatically. It adapts to tube material, color, and sealing variations with high accuracy.

A Thermal Camera Vision System detects underheated seals, hot spots, burnouts, air entrapment, contamination, and other thermal-related sealing defects that traditional rule-based systems often miss.

DeepInspect® uses AI-based OCR (Optical Character Recognition) and OCV (Optical Character Verification) to read and validate printed text and numbers on high-speed lines, achieving 99.5% accuracy.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect® requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect® uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

A line demo for DeepInspect®’s cap inspection system can be conducted within a day