AI detection of bottle induction seal defects

DeepInspect® – Computer vision bottle sealing inspection software

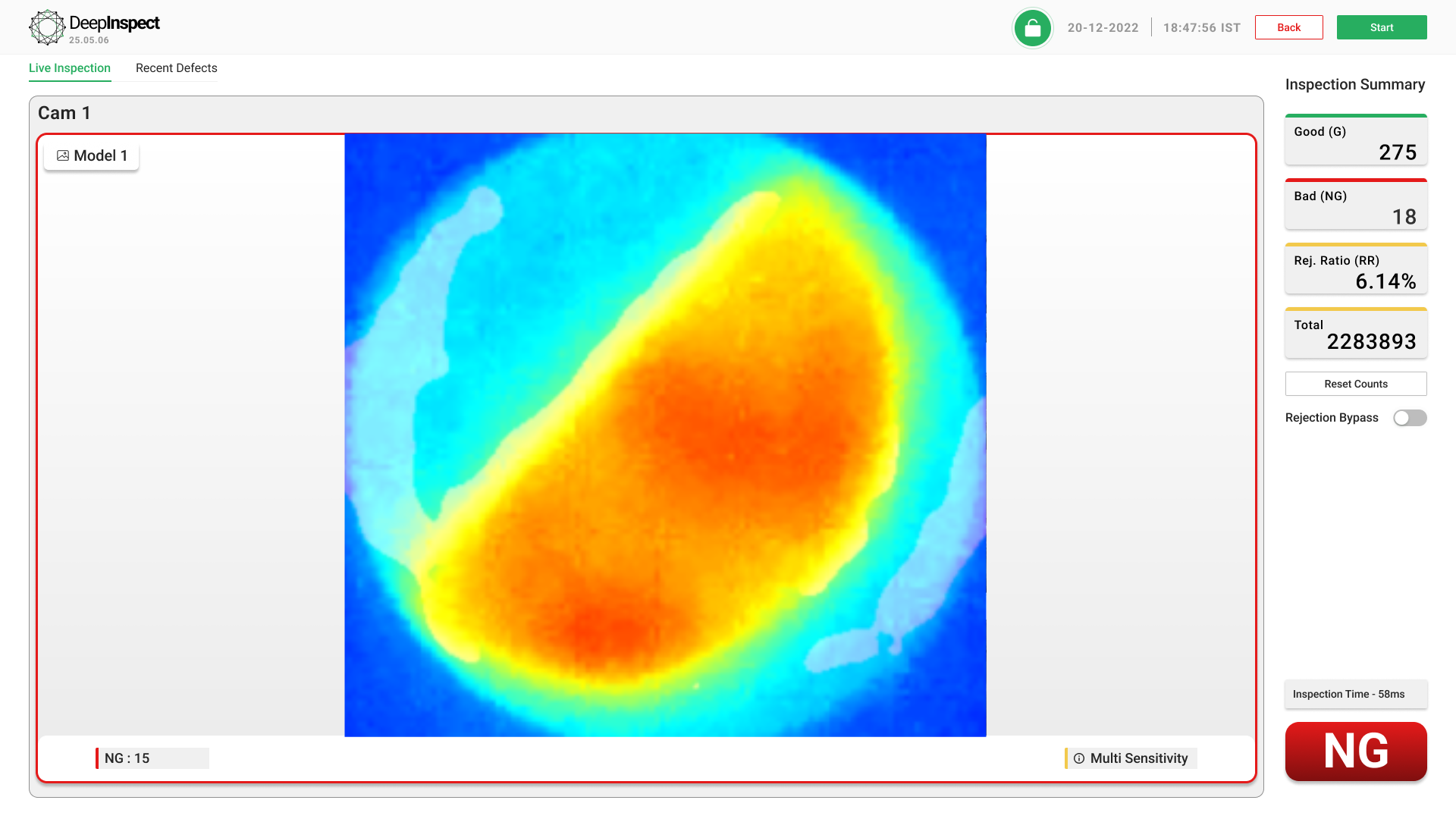

AI-powered bottle sealing inspection using DeepInspect® delivers unmatched sealing accuracy, integrity, and high repeatability across FMCG, pharma, food, and beverage lines — a capability traditional rule-based vision systems consistently lack. DeepInspect® combines deep learning with thermal cameras to analyse heat profiles and sealing temperature distribution, detecting weak seals, over-sealing, misaligned induction seals, missing foil liners, wrinkled foils, and micro-leak-causing pinholes in real time.

Unlike rule-based systems that struggle with variability, low accuracy, and high false positives, DeepInspect® offers automated defect classification, minimal data requirement, and reliable induction seal inspection even across changing products, shifts, and line conditions. Its AI vision engine verifies foil bonding, sealing uniformity, torque-related sealing issues, and cap-to-bottle consistency at high speeds.

Seamlessly integrating with any bottling line, DeepInspect® provides continuous monitoring, real-time alerts, and 360° AI sealing verification — enabling manufacturers to eliminate sealing failures early and achieve true zero-defect bottle sealing at scale.

USECASE

Defects Detected by DeepInspect®

DeepInspect® detects all defects, such as

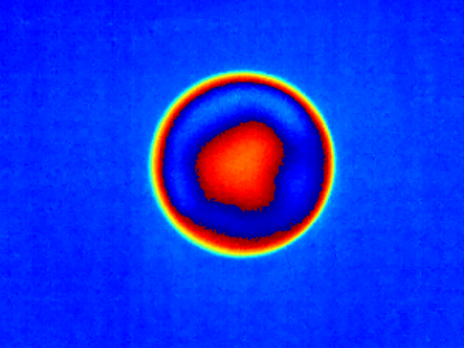

Identifies overheating, under-heating, burnt seals, and uneven heat distribution with high accuracy

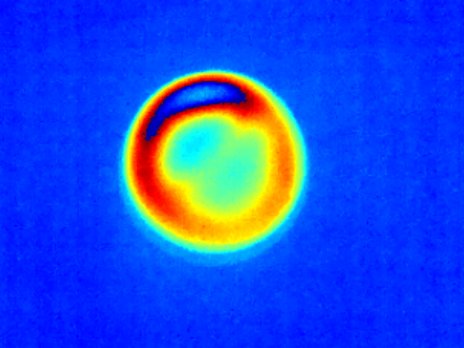

Detects misaligned foils, off-center seals, wrinkles, and placement errors with precision

Covers issues like poor foil bonding, weak adhesion, incomplete heat fusion, and seal gaps.

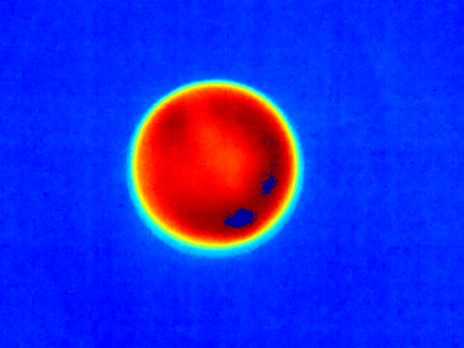

Accurately detects wads missing, mispositioned liners, delamination, and improper bonding during sealing

Computer vision sealing verification & defect detection

Wad Defects

Non-Uniform Sealing

Overheat Sealing

Underheat Sealing

Automated bottle sealing quality inspection for Pharma & FMCG manufacturers

Say no to rule-based systems.

High-speed inspection system for weak heat seal defects. High repeatability

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

1000+PPM: High-speed inspection, detecting 1000+ parts per minute

Zero-defect induction sealing AI with 99.5% accuracy

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

A Power packed solution

for all your sealing quality inspection requirements

Interested in AI sealing inspection for FMCG bottles?

Book a free demo!

Inquiry Form

It is an automated, non-contact system that uses AI and thermal imaging to verify bottle sealing quality, detect sealing defects, and ensure zero-defect packaging.

DeepInspect® combines AI vision with thermal cameras to analyze heat patterns, foil bonding, and sealing uniformity in real time.

Weak seals, over-sealing, misaligned foils, missing wads, partial seals, wrinkled foils, and micro-leaks.

Rule-based systems lack repeatability and accuracy. DeepInspect® offers high repeatability, 99.5%+ accuracy, and low data requirements.

Yes. DeepInspect® removes human subjectivity by providing consistent, 24/7 automated inspection with far better repeatability, ensuring no sealing, surface, or print defect reaches the market.

Yes — it identifies overheating, under-sealing, uneven heat distribution, and burnt foil defects.

Absolutely. It supports high-speed, high-volume induction sealing inspection across FMCG, pharma, and beverage lines.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

Yes, DeepInspect® detects wad missing, wad misalignment, foil delamination, and improper liner placement instantly.

Zero-defect sealing, reduced rejections, improved process control, real-time alerts, and superior packaging reliability.