AI-based Machine Vision Software for Manufacturing

Related Articles

How Machine Vision Software is Transforming Manufacturing?

As manufacturing processes become increasingly automated, the need for precise, real-time decision-making has grown dramatically. One of the most transformative technologies driving this change is manufacturing machine vision software for defect detection that gives machines the ability to “see” and interpret their environment. Before diving into how this technology is applied in manufacturing, let’s first understand what machine vision actually is.

What Is Machine Vision?

Machine vision is simply the use of industrial cameras and the best machine vision inspection software to help machines “see” what’s happening on a production line. Instead of relying on people to inspect parts or spot defects, computer vision AI tools for manufacturing capture images of every product and check them against the required standards. It works through a combination of industrial cameras, controlled lighting, lenses, and software that can quickly interpret what the camera is seeing.

In manufacturing, industrial AI inspection is especially useful because production runs fast and quality expectations are extremely high. Even the most skilled human inspector can miss small defects or struggle to maintain the same level of attention through an entire shift. Machine vision for manufacturing takes over this repetitive work and delivers the same level of clarity and consistency from the first part to the last.

A typical setup captures an image, analyzes it within a fraction of a second, and then signals whether the product meets the quality criteria. If something is wrong, the system can alert the operator or automatically reject the part.

Today, industrial machine vision software has become a core part of modern factories because it helps manufacturers maintain high quality, reduce waste, and keep production moving without interruption.

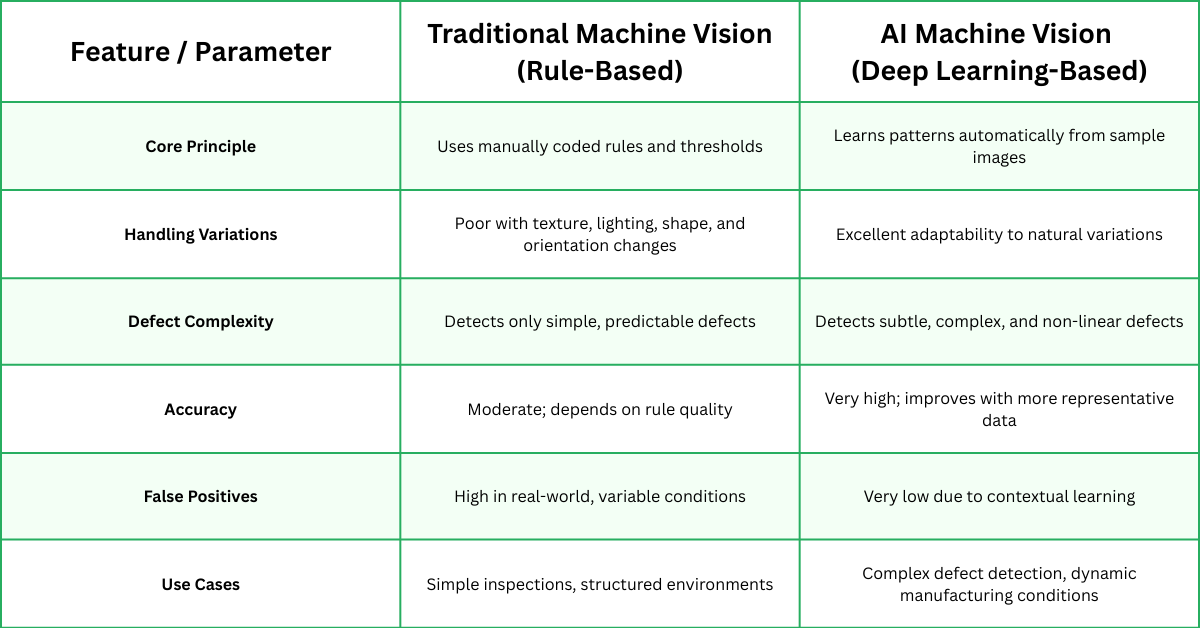

Traditional Machine Vision vs AI Machine Vision

Over time, machine vision technology has evolved into two distinct approaches: Traditional Machine Vision and AI-based Machine Vision. While both aim to detect defects and ensure quality, they differ fundamentally in how they interpret images and make decisions. Let us dive deeper

Traditional Machine Vision

Traditional machine vision works on a very straightforward idea: engineers define the exact rules a system should follow, and the software checks every image against those rules. It uses fixed thresholds, geometric measurements, and simple logic to decide whether something is right or wrong. This approach is effective when products look the same every time and the environment doesn’t change much. But in real factories, things rarely stay perfect. A small shift in lighting, a slightly different surface finish, or a natural variation in material can confuse a rule-based system. It may flag good parts as defective or fail to catch issues that fall outside its predefined logic. As manufacturing becomes faster and more varied, teams often find themselves constantly tweaking parameters just to keep the system stable. Traditional machine vision struggles in situations where products or conditions don’t behave the same way every day.

AI Machine Vision

AI machine vision takes a very different path. Instead of writing rules, engineers give the system examples—images of good parts,images of defects—and the software learns the patterns on its own. It understands textures, shapes, subtle variations, and even defects that don’t look identical every time. Because of this learning-based approach, AI handles real-world variation far better than rule-based systems. Changes in lighting, surface reflections, or minor product differences don’t throw it off easily. Once trained, the system remains stable without constant retuning, which saves a huge amount of engineering effort. It also adapts quickly when new SKUs or updated designs are introduced. For manufacturers dealing with complex surfaces, high-speed lines, or a mix of different components, AI machine vision simply delivers more reliable results. It brings accuracy, flexibility, and long-term consistency that traditional systems often struggle to match.

Comparison Table - Traditional Vs AI Machine Vision

AI Machine Vision Applicaton in Manufacturing Industry

Manufacturers today increasingly prefer the best AI machine vision software because it solves many of the limitations that traditional rule-based vision systems struggle with. Modern production lines deal with natural variations in lighting, texture, and product appearance, and AI handles these changes far more gracefully. Instead of relying on rigid rules, AI machine vision software learns from real examples, making it far better at catching subtle, low-contrast, or unpredictable defects that often slip past older systems. This leads to significantly higher accuracy and far fewer false positives, which matters when you’re running high-speed lines or managing multiple SKUs.

Another reason AI vision systems are becoming the preferred choice is the speed at which they can be deployed. The best machine vision software for manufacturers now requires minimal images, trains quickly, and adapts easily to new product variations. This reduces engineering effort, downtime, and maintenance costs. Manufacturers also value the scalability—AI models can be replicated across plants with very little reconfiguration.

Ultimately, AI machine vision is chosen because it delivers consistency, flexibility, and long-term reliability. Whether it’s Automotive, Pharma, FMCG, or Electronics, AI-powered visual inspection software provides the accuracy and stability that modern manufacturing demands.

Supervised vs Unsupervised Learning: How AI Inspection Software for Factories Actually Learns?

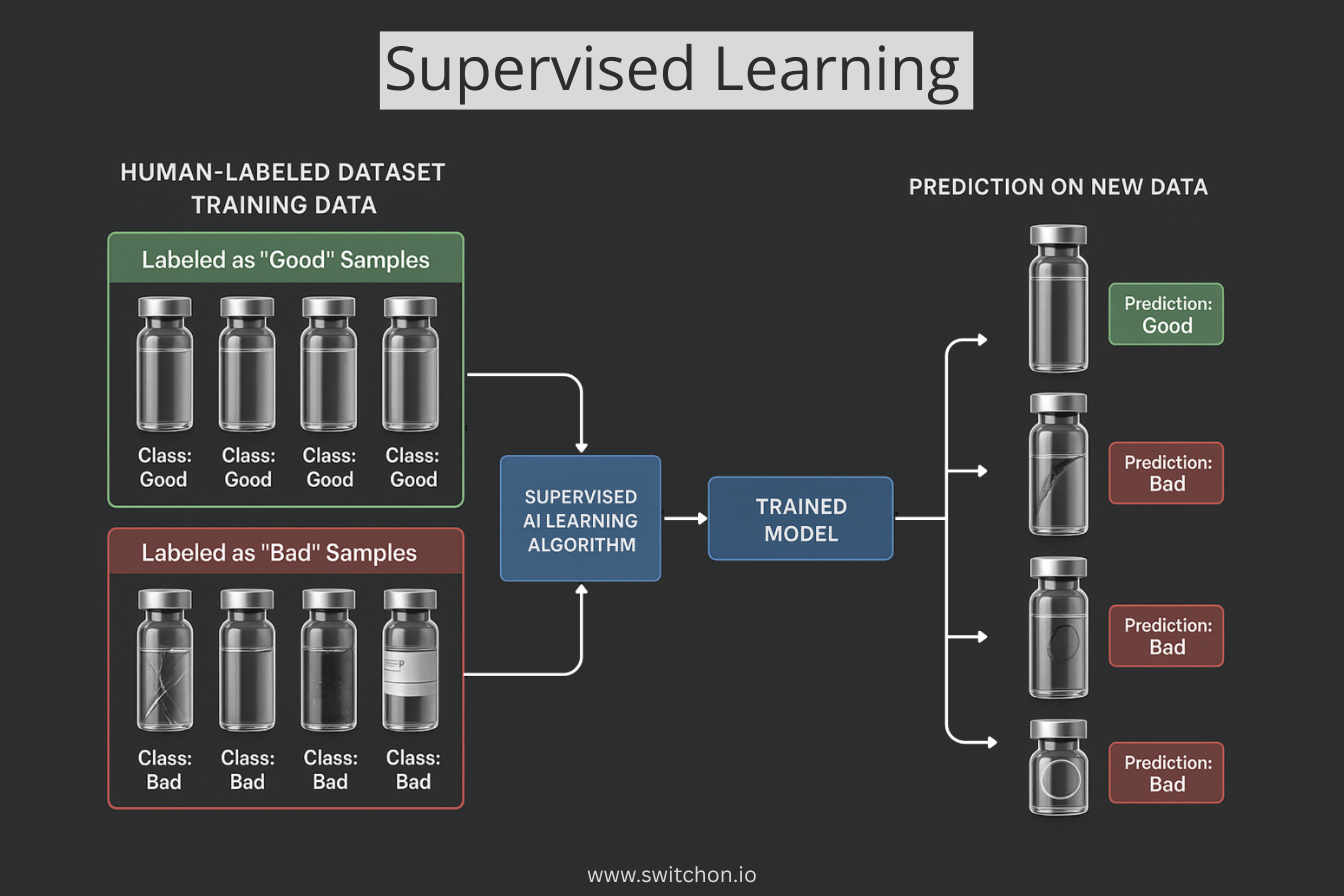

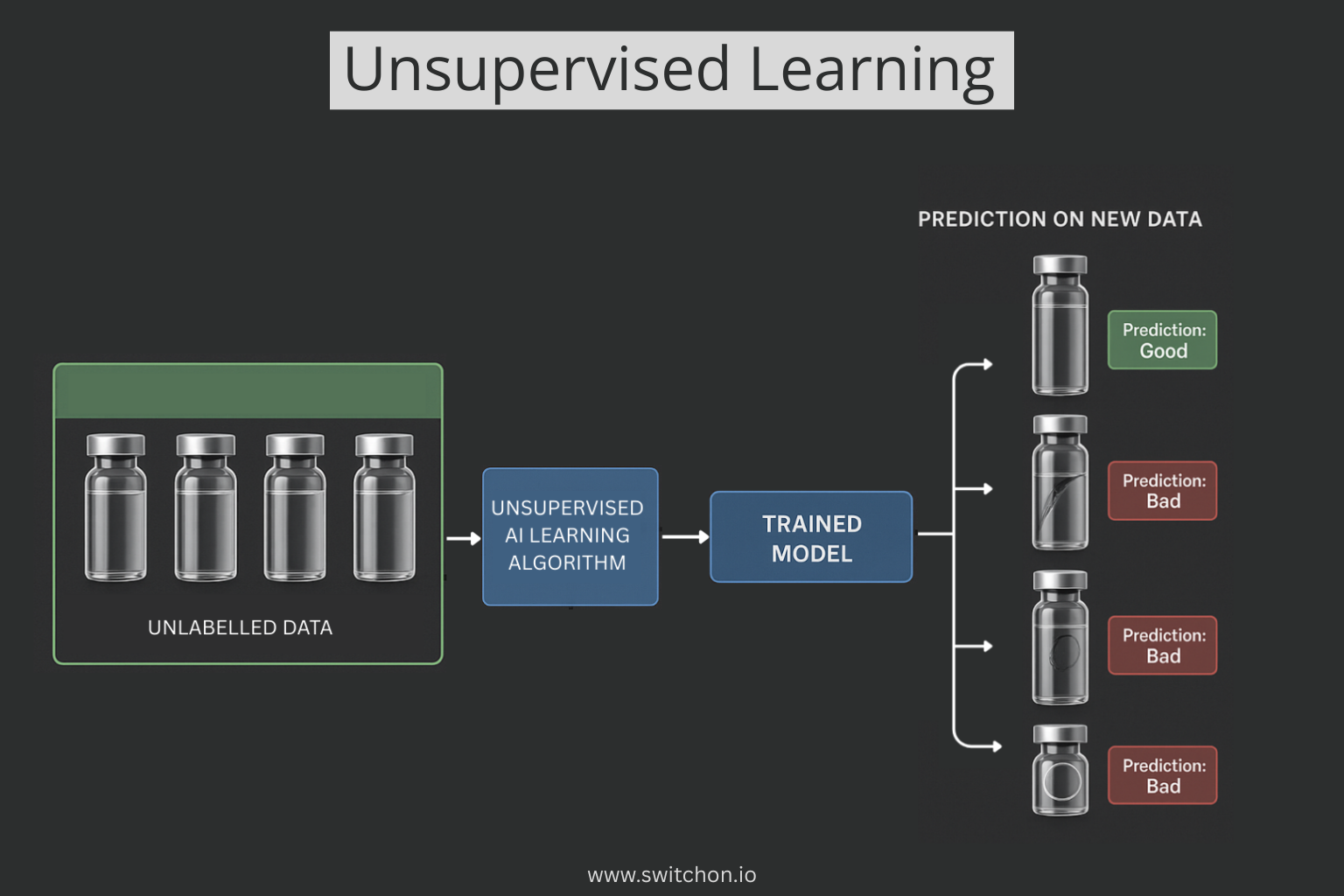

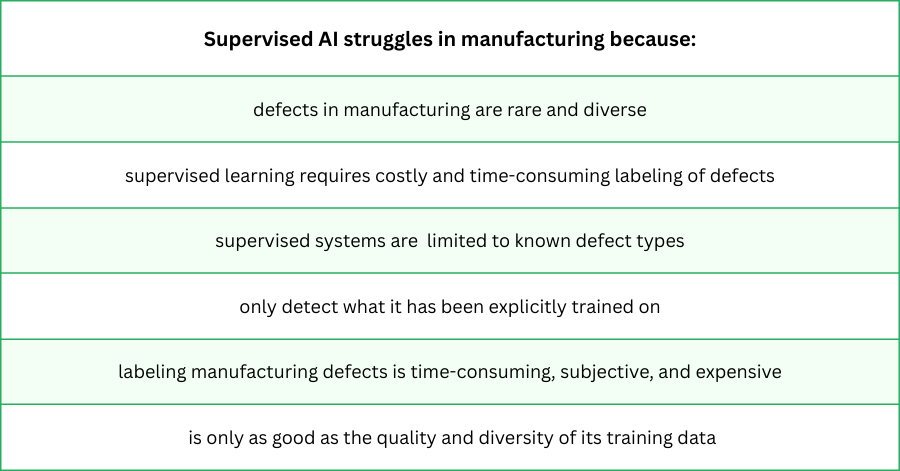

Machine vision softwares are broadly classified into two learning approaches: supervised AI and unsupervised AI. These classifications define how the systems learn to interpret visual data and make inspection decisions

Why Unsupervised AI Outperforms Supervised Vision Systems

Unsupervised AI has quickly become the preferred option for many manufacturers because it solves one of the biggest problems in industrial inspection: the lack of defect data. In most factories, defects are rare, inconsistent, and often unpredictable, which makes it extremely difficult to collect and label enough defective samples for supervised learning. Unsupervised Vision AI software for production lines removes this dependency entirely. It learns only from good parts, building a deep understanding of what “normal” looks like across textures, shapes, and surface variations. Anything that deviates from this learned normal pattern is flagged automatically, even if the defect has never been seen before. This makes unsupervised AI especially powerful for early defect detection, high-mix production lines, and environments where new variations appear frequently. It also reduces engineering effort since teams no longer have to label thousands of images or define defect categories manually. Once deployed, unsupervised models stay stable with minimal tuning, offering long-term reliability. For manufacturers seeking a flexible, scalable, and low-maintenance inspection solution, unsupervised AI often proves to be the most practical and future-ready choice.

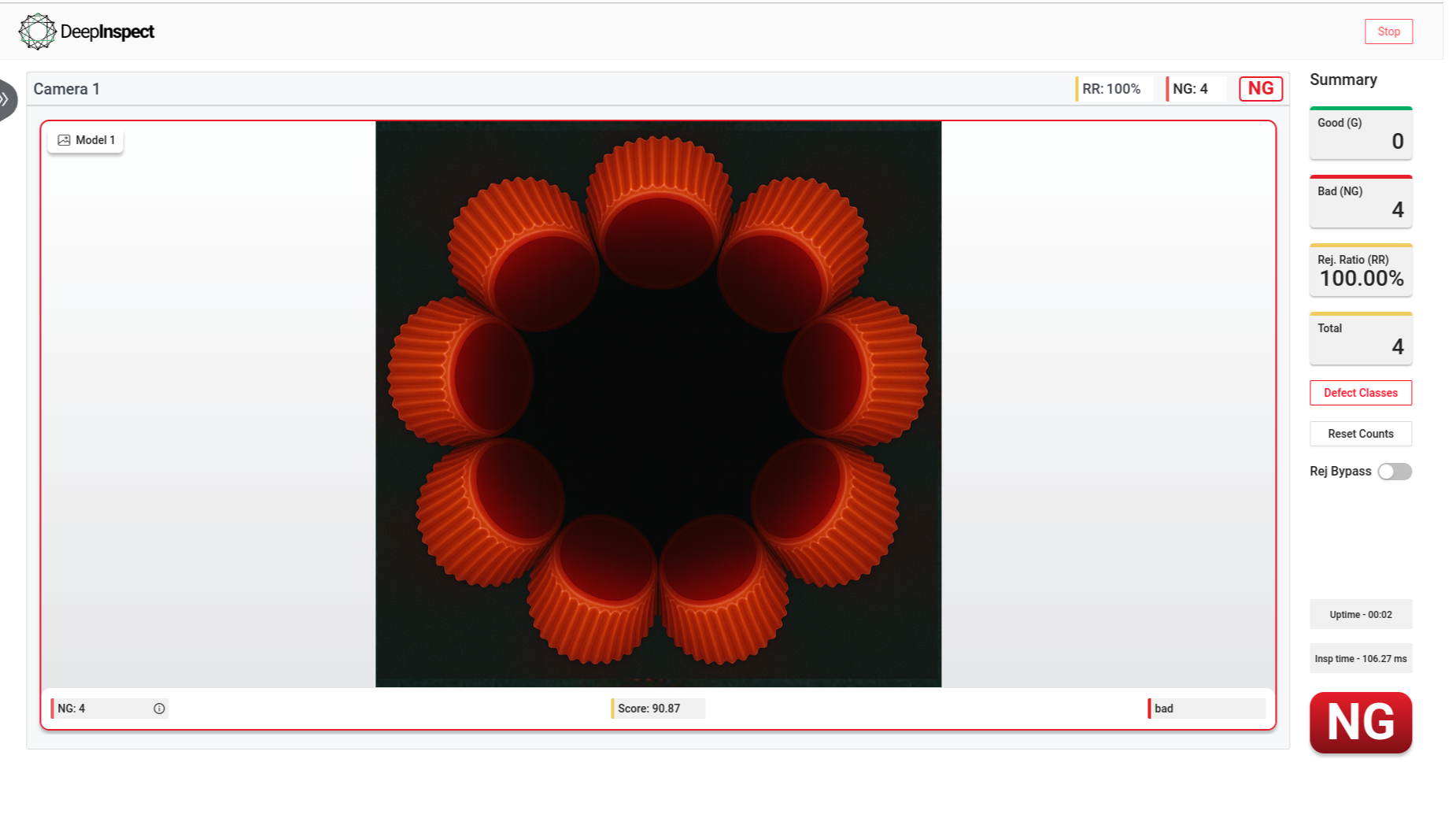

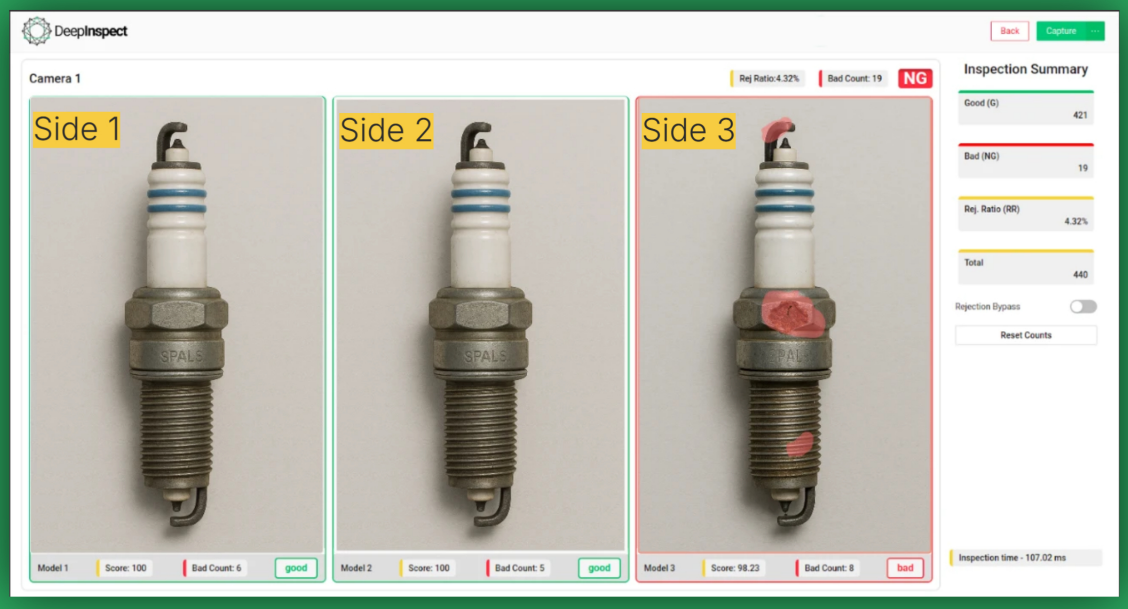

DeepInspect®- Best Unsupervised AI Machine Vision Software for Manufacturers

DeepInspect is the best machine vision software with great customer reviews. It is designed to automate and optimize quality control in manufacturing environments. DeepInspect leverages advanced deep learning models that can be trained quickly using fewer than 200 good-part images, enabling faster deployment compared to traditional machine vision systems that need large defect libraries. DeepInspect routinely delivers 99.5%+ accuracy in defect detection across multiple categories of inspection. The inline inspection software for manufacturing is engineered for high-throughput lines, capable of inspecting hundreds to over a thousand parts per minute, depending on camera setup and product complexity. This performance ensures that inspection keeps pace with automated manufacturing processes.

Why DeepInspect®?

- Requires <200 good images for model training

- End-to-end training completed in under 45 minutes

- 99.5%+ defect detection accuracy

- <0.5% false positives, outperforming rule-based tools

- Real-time inspection at very high speeds

- Line trial in just one day

- Supports line-scan, area-scan, and thermal cameras

- Robust to lighting, surface variations, and environmental noise

- Scales across factories with unified analytics and downloadable quality reports

DeepInspect® Usecases

Surface Defects

OCV/OCR

Object detection & Counting

Thermal Inspection

Dimension Check

Part absence & Presence

DeepInspect® Usecases- Industry wise

Automotive

Surface defect detection on metal, cast, machined, and painted parts

Dimensional and geometric verification

Assembly and weld inspection

Presence/absence checks

Pharma

Blister pack inspection

Label OCR/OCV verification

Integrity of induction sealing and wad detection

Print and code quality checks

FMCG

Cap sealing defects

Fill-level inspection

Bottle, jar, and pouch defect detection

Packaging alignment and contamination checks

Electronics

PCB inspection

Connector quality inspection

Micro-solder joint analysis

High-precision dimensional measurements

DeepInspect® is the best AI machine vision software for manufacturers, built specifically for industrial environments that demand precision, performance, and scalability. It combines deep learning, advanced image processing, automated model training, and production-ready deployment tools into a unified platform.

Requires <200 good images for model training

End-to-end training completed in under 45 minutes

99.5%+ defect detection accuracy

<0.5% false positives, outperforming rule-based tools

Real-time inspection at very high speeds

Rapid deployment in 1 day on live production lines

Supports line-scan, area-scan, and thermal cameras

Robust to lighting, surface variations, and environmental noise

Scales across factories with unified analytics and reporting

Looking for the best Machine Vision software? Let's talk

Inquiry Form

Machine vision software is a technology that uses industrial cameras and computer vision software to automatically inspect products on a production line. It helps manufacturers detect defects, verify quality standards, and ensure consistent output without manual inspection.

AI machine vision software uses deep learning and computer vision AI to identify defects that traditional inspection methods may miss. It adapts to variations in products, improves detection accuracy, and reduces false rejects in manufacturing quality inspection.

Machine vision software is designed specifically for industrial automation and inspection, while computer vision software is a broader technology used across industries. In manufacturing, machine vision integrates cameras, lighting, and AI visual inspection software for real-time quality control.

A machine vision system for manufacturing typically includes industrial cameras, lenses, controlled lighting, image acquisition hardware, and vision inspection software that analyzes images and makes pass/fail decisions.

AI visual inspection software can detect surface defects, cracks, scratches, dents, dimensional variations, missing components, and labeling issues using automated defect detection software on production lines.

Yes. Industrial machine vision software is built for inline inspection and can analyze images in milliseconds, making it ideal for high-speed manufacturing environments where manual inspection is not feasible.

Machine vision inspection software is widely used in automotive, FMCG, pharma, electronics, food & beverage, and packaging manufacturing for automated quality control and defect prevention.

By automating inspection, machine vision software reduces labor dependency, minimizes scrap, prevents rework, and lowers warranty claims—resulting in improved efficiency and reduced overall manufacturing costs.

Manufacturers should evaluate accuracy, ease of deployment, AI capabilities, scalability, integration with PLCs, and the ability to handle multiple defect types when selecting the best machine vision software for manufacturing.

AI-powered visual inspection software is essential for smart factories and Industry 4.0 because it enables real-time decision-making, continuous quality monitoring, and data-driven process optimization across production lines.