AI- POWERED BEARING INSPECTION

DeepInspect- Visual Inspection Software for bearing inspection- tapered, ball, roller bearings, etc.

DeepInspect transforms bearing visual quality inspection through advanced machine vision and AI-powered bearing defect detection, enabling real-time identification of critical bearing defects. With precise bearing surface defect detection, it swiftly detects issues like cracks, surface scratches, dents, burrs, and all sort of visual defects. The system’s capabilities extend to dimensional accuracy verification and bearing ball count validation, improving the precision of bearing inspections. DeepInspect’s non-contact bearing inspection method minimizes the risks and errors associated with manual processes, providing a more reliable and efficient alternative. It integrates high-speed imaging and automated visual bearing inspection, enhancing throughput and reducing inspection times. The system also excels in raceway surface inspection, ensuring bearings meet the highest standards of quality. By focusing on minute defects, DeepInspect optimizes bearing durability and performance, offering manufacturers a more robust, accurate, and efficient solution for quality assurance in bearing production.

APPLICATION

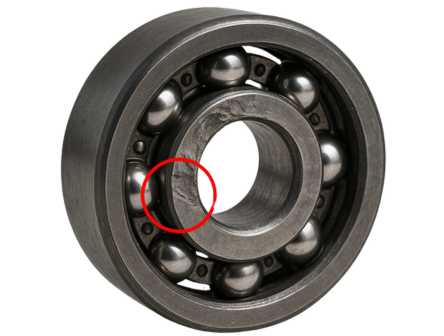

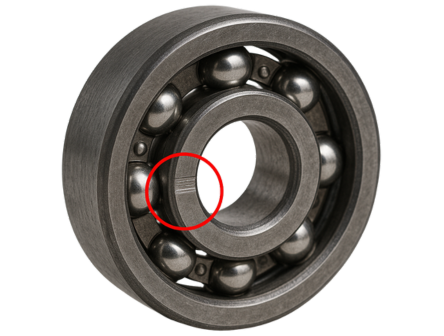

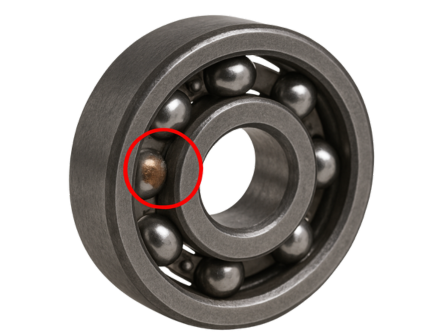

Grinding defects like surface scratches, uneven grinding marks, etc. can be identified

Turning defects such as face damage and tool wear can be detected

Assembly defects including misalignment, rust, or missing lubrication can be pinpointed

Optical character verification ensures accurate text, batch codes, and serial numbers

Impact

DeepInspect, bearing quality inspection software significantly improves bearing defect detection by automating the inspection process, ensuring precise identification of issues like surface scratches on bearings, bearing misalignment detection, OCV/OCR and wear analysis. It enhances efficiency, reduces errors, and ensures superior bearing quality control and compliance with industry standards.

Detect all kind of bearing defects with 99.5% Accuracy

Turning Defects

Grinding defects

Assembly Defects

OCV/OCR

Interested in Streamlining Bearing Quality Inspection Process?

Drop us a line or shoot us an email

Inquiry Form

DeepInspect automates bearing defect detection, ensuring accurate identification of issues like surface scratches on bearings, bearing misalignment detection, etc. improving overall inspection efficiency and product quality.

DeepInspect can detect all kinds of bearing visual defects such as surface scratches, misalignment, absence/presence, and other critical defects that may affect bearing performance

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection in bearings

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection systems for bearing.

A line demo for DeepInspect’s bearing inspection system can be conducted within a day, showcasing its fast implementation and ease of use.