AI- POWERED GLASS BOTTLE BORE INSPECTION

Industry : FMCG & Pharma

Client : Manufacturer of high-quality glass bottles

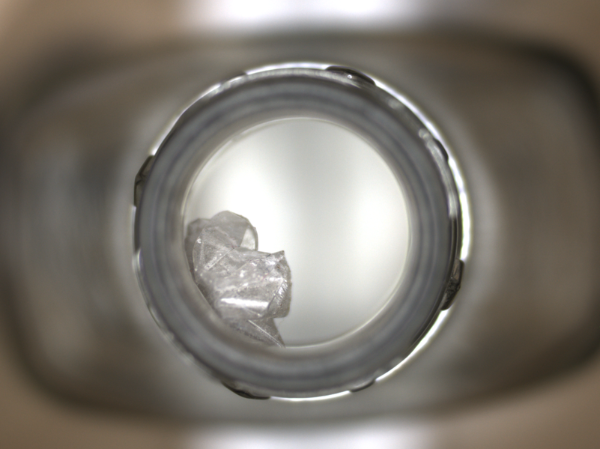

Our customer, a leading manufacturer of Soda Lime Flint & Amber Glass containers, serves the Food, Pharmaceutical, Beverage, Liquor, and Beer industries. With a 320 TPD melting capacity across two furnaces and 10 I.S. machines, they faced challenges in manually inspecting bore diameter chocking, mouth differences, and foreign particles present in the neck portion of glass bottles. By using SwitchOn DeepInspect®️, they achieved 99.5% inspection accuracy, improving quality and efficiency.

CASE STUDY

Achieved 99.8% accuracy, ensuring precise detection of neck defects

0.14% false positive rates, minimizing

unnecessary rejections

0.14% false positive rates, minimizing unnecessary rejections

Since implementation, the customer has reported zero complaints

Impact

Following the implementation of DeepInspect®, our customer experienced significant improvements in their operations.

Curious to Know More?

Download the full case study and explore how our customer leveraged DeepInpsect® to achieve zero defect lines