AI- POWERED 360° SPARK PLUG INSPECTION

DeepInspect®- automated visual inspection software for Spark Plugs

Traditional AI inspection systems may sound promising, but many fall short when it comes to reliably detecting critical spark plug surface defects like micro-cracks, flash, and ceramic misalignments. These systems often require multiple cameras and complex setups, resulting in higher costs and maintenance challenges. DeepInspect’s 360° visual inspection system for spark plugs changes the game — using just a single-camera setup. This AI-based spark plug inspection solution captures complete 360-degree surface data with zero blind spots, enabling highly accurate detection of even the most minute defects. With DeepInspect®, manufacturers can ensure consistent spark plug quality, reduce false positives, and streamline their automated inspection process — all without bulky hardware or extensive training data, while delivering unmatched precision and speed.

APPLICATION

Identifies cracks on spark pug surface using advanced Vision system

Detects spark plug surface defects like weld defects, dents etc.

Checks for spark plug wash absence presence etc. with high accuracy

Spots spark plug thread damages, burrs, crack defects on the ceramic etc.

Impact

DeepInspect revolutionizes Spark Plug quality control by seamlessly detecting cracks, dents, weld defects,etc. Its AI-based spark plug inspection ensures consistent Spark Plug quality standards, enhancing efficiency and reducing waste in production.

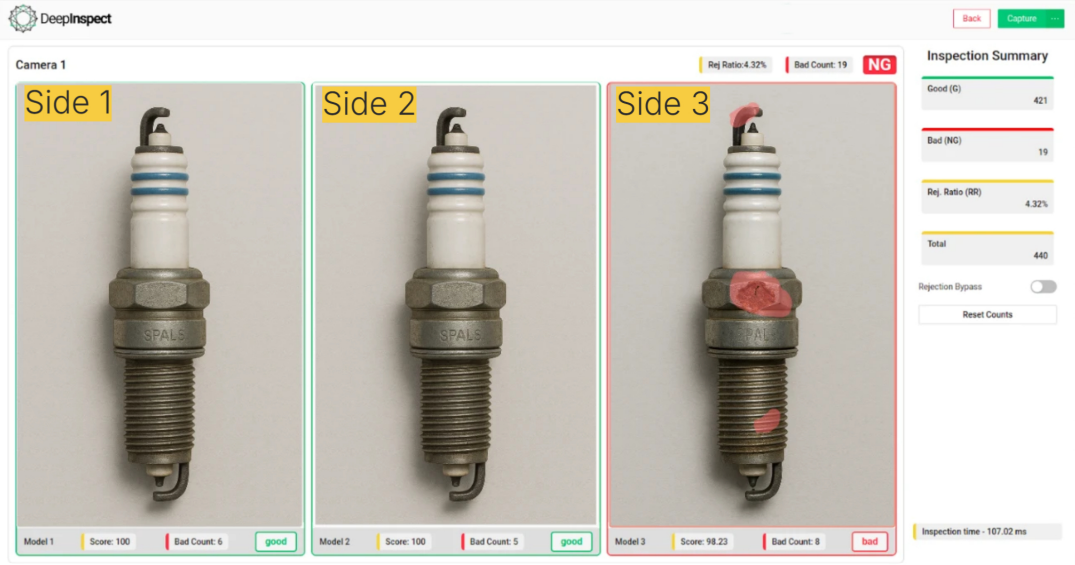

Spark Plug Manufacturing Inspection with 99.5% Accuracy

Weld Defects

Ceramic Defects

Thread Defects

Wash Presence/ Absence

360° Spark Plug Inspection Using One Camera System

Interested in Streamlining Spark Plug Quality Inspection Process?

Drop us a line or shoot us an email

Inquiry Form

DeepInspect offers 99.5% accuracy with less than 0.5% false positive rates, making it a reliable solution for automated quality control of Spark Plugs.

DeepInspect accurately detects all kind of surface defects including micro-cracks, flash, ceramic insulator misalignments, missing wash, surface dents, electrode damage, and other cosmetic and structural defects.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection systems for spark plugs.

A line demo for DeepInspect’s spark plug inspection system can be conducted within a day

Yes, DeepInspect is designed to be easily adaptable to different spark plug designs and sizes with minimal changeover or retraining effort.