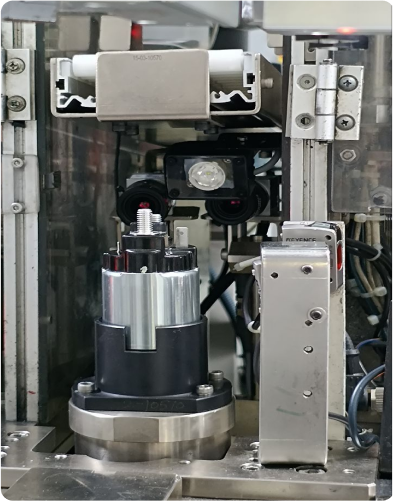

AI-Powered Defect Detection for Starter Switches

Industry : AUTOMOTIVE

Client : Leading Automotive Component Manufacturer

Summary: Our client is a leading global supplier of automotive components with a strong presence in Asia, North America, and Europe. They develop technologies for hybrid and electric vehicles, autonomous driving, and connected cars. To detect defects in starter switches’ caulking, they used the SwitchOn DeepInspect system. This automated system identified defects as small as 100-150 microns in under 11 seconds per part, improved defect detection, maintained quality, reduced labor costs, and increased efficiency.

CASE STUDY

Defects as small as 100-150 microns were able to detect

Inspection completed in less than 11 seconds per part

Able to seamlessly inspect two variants of starters

The starter switches met the required quality standards

Impact

Following the implementation of DeepInspect, our customer experienced significant improvements in their operations

Curious to Know More?

Download the full case study and explore how our customer leveraged DeepInpsect to achieve zero defect lines