Experience

Zero

Defects

AI- Powered Visual Quality Inspection for Automotive Manufacturers

Inquiry Form

Automotive

Helping auto brands detect defects faster with DeepInspect®. No guesswork, just precision!

DeepInspect®. Zero Defects

DeepInspect®, AI-Powered visual quality inspection software helps Automotive manufacturers inspect surface defects like dents, scratch, burrs etc. upto 150 microns. Read and verify optical characters including special characters like &, *, % etc. Help measure dimensions. All with 99.5% accuracy

DeepInspect® Industry Applications

Tyre Inspection

OCV/OCR, Pattern Defects, Cracks, etc.

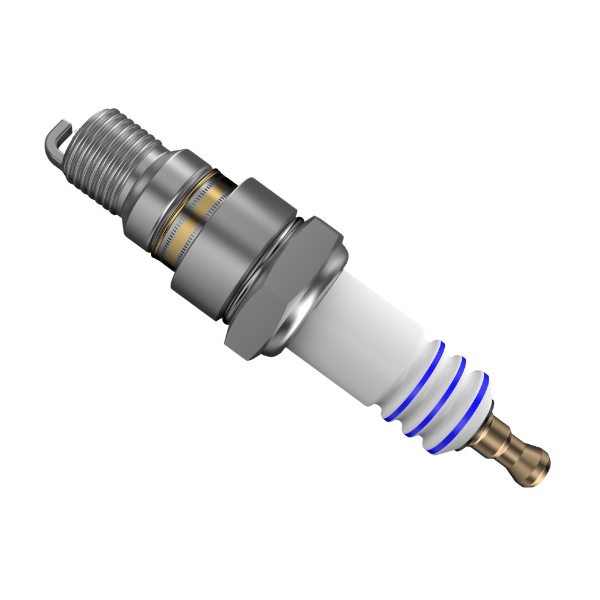

Spark Plug Inspection

Cracks, dents, dimension, etc.

Connecting Rod

Burr, Dents, Scratches, etc.

Brake Inspection

Crack, burr, surface damages, etc.

Engine Inspection

Engine Assembly, Sealant, OCV/OCR, etc.

Oil Filter Inspection

Fin Defects, Cuts, Surface Defects, etc.

Fuel Injector

O Ring defects, Dents, Scratches etc.

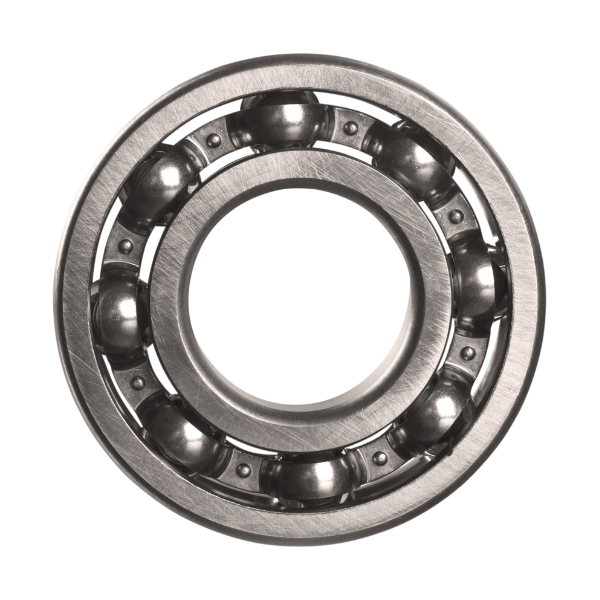

Bearing Inspection

Dents, Scratch, Burr, etc.

Suface defects, dents, scratch, etc.

AI Powered Sealing Inspection

Why DeepInspect®?

Operator friendly. Train AI models without the need for a internal data science team. Dedicated team of project managers

High-speed AI inspection at

1000+ parts per minute

DeepInspect supports up to 8 industrial cameras in a single application, 1.3 to 20 megapixels, global and rolling shutter cameras

Runs high speed AI based inspection up to 1000+ PPM*; dependon multiple factors such as SKU, light, material handling, etc.

TCPI/IP and modbus enabled communication. Successfully integrated with Siemens, Delta, Omron, and Mitsubishi IOs

Seamlessly deploy 50+ models in a single system and continously improve performance with DeepInspect Train

Ability to automatically switch SKUs based on external triggers for seamless inventory and process management

Enable traceability applications with 10k image save and inbuilt analytics to process and analyze collected data, providing actionable insights

Customer Testimonial

Interested in Streamlining Quality Inspection Process?

Contact us today for a line demo and feasibilty report