OCR/OCV on Automotive Components

OCR/OCV on Automotive Parts

Related Articles

Introduction

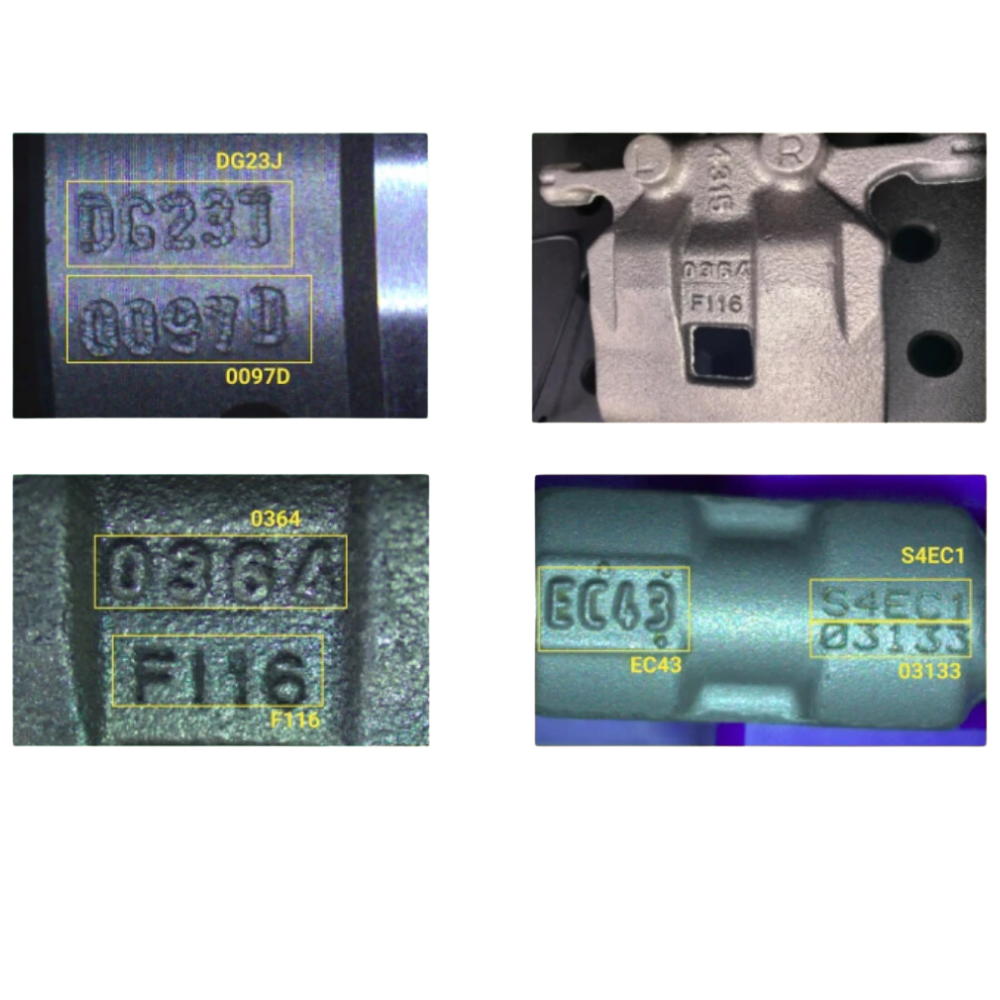

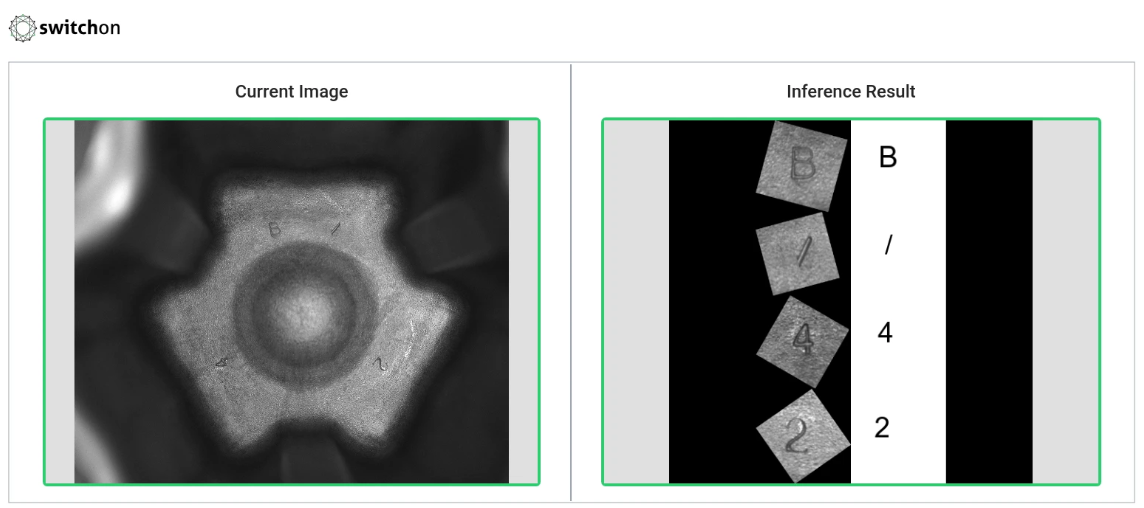

Optical Character Recognition (OCR) and verification on challenging-to-detect automotive parts have been long standing issues in the industry. Traditional machine vision systems have consistently fallen short of achieving the coveted 99.99% detection rates, leading to inefficiencies and quality control challenges. Over the past few years, our dedicated research team has been tirelessly exploring innovative solutions to tackle this problem. Today, we are thrilled to introduce our groundbreaking solution: DeepInspect Read. DeepInspect Read harnesses the power of advanced deep learning algorithms to deliver exceptional accuracy and speed. This cutting-edge technology sets new benchmarks for compliance and quality control in manufacturing processes, ensuring that you meet the highest standards with confidence.

Key Features in Quality Inspection

100% Detection Rate on DPM: Achieves perfect detection on Direct Part Marking (DPM) with reflective custom fonts, ensuring complete accuracy in reading critical information.

High Accuracy in Various Conditions: Maintains exceptional accuracy across different surfaces and lighting conditions, ensuring reliable performance in diverse manufacturing environments.

OCV in Die-Casted Characters: Expertly handles Optical Character Verification (OCV) for die-casted characters eg,Engine Piston, Brake parts, Machined steel/Aluminium or Plastic parts.

Comprehensive Character Recognition: Supports a wide range of characters, including special symbols such as #, @, ₹, and /, ensuring complete coverage and accuracy.

Superior Accuracy: Achieves 99.9%+ accuracy in character detection, significantly reducing the risk of errors and ensuring the integrity of your products.

Robust Error Detection: Maintains a false-positive rate of less than 0.5%, adapting seamlessly to minor variations in print quality and environmental factors.

Seamless Printer Integration: DeepInspect Read integrates effortlessly with existing printer systems, such as VideoJet Printers, enabling real-time verification and reducing the need for manual checks.

AI-Driven Adaptability: Utilizes proprietary edge AI technology to adapt to varying production conditions, ensuring consistent performance and reliability.

Applications of OCV/OCR in Automotive Manufacturing:

Part Identification: Accurately read and verify serial numbers, barcodes, and other critical identifiers on automotive parts.

Label Verification: Ensure that labels on packaging and parts meet regulatory and quality standards.

Production Line Monitoring: Continuously monitor and verify printed text and codes in real-time, maintaining high standards throughout the manufacturing process.

DeepInspect Read is the OCR solution for the automotive industry, delivering unparalleled precision, speed, and reliability. It has undergone rigorous testing on a range of complex automotive parts, proving its exceptional performance and dependability.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.