Leading Automaker’s Implementation of DeepInspect®

Leading Automotive Manufacturer's Implementation of the SwitchOn DeepInspect® System

Related Articles

Introduction

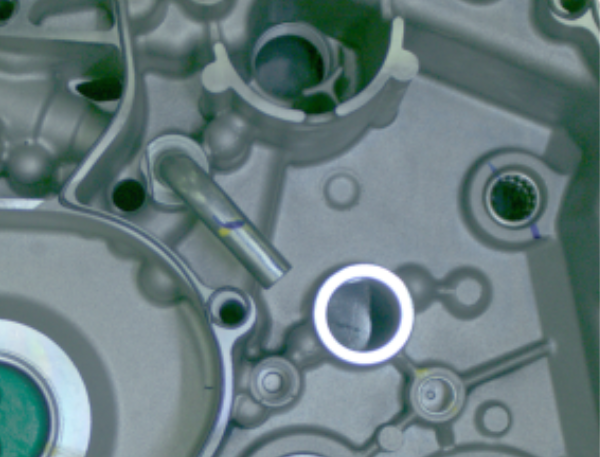

A leading automotive manufacturer faced a challenge with manual sealant inspection in crankcases, leading to errors and inefficiencies. Issues like missing or uneven sealant resulted in oil leaks, reduced engine performance, and potential engine damage. This highlighted the urgent need for an automotive vision inspection system.

DeepInspect®- AI Powered Sealant Inspection Software

DeepInspect is an AI powered automotive quality inspection software that helps manufacturers automate crankcase sealant inspection across all SKUs on their production line. Manufacturers can take a big step forward by implementing the SwitchOn DeepInspect® system. The setup includes:

DeepInspect Software

Industrial Camera

Industrial Lighting

PLC

Industrial Controller with i5 and GPU

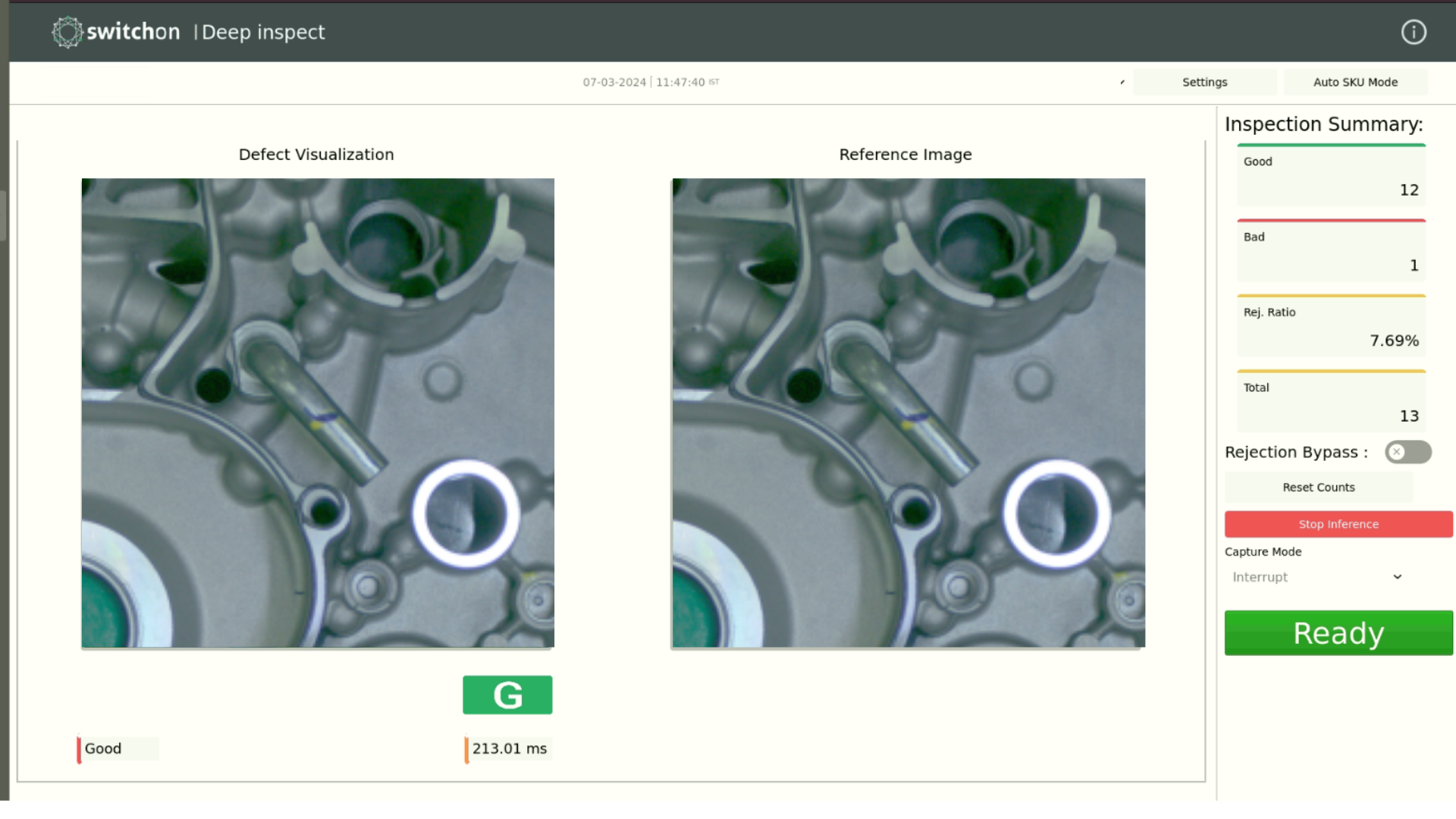

The software need fewer than 200 good sealant images and just 45 minutes for model training and validation. The entire process, from capturing the image to displaying the inspection results, is completed in less than one second, dramatically improving the speed and accuracy of their production line

Why DeepInspect® for automated sealant inspection?

After the implementation of the SwitchOn DeepInspect® system, our customer’s sealent quality inspection process has transformed completely. The system not only eliminate the need for manual labor but also significantly enhanced efficiency and reduced human error. With an impressive accuracy rate of 99.5%, our customer was able to ensure that only high-quality products reached the market.

Successfully carried out sealant inspection for thickness, continuity, sealant presence/absence, etc.

The false positive rate minimized to just 4%, ensuring all good sealants are accurately identified and correctly classified

Boosted vehicle performance and effectively eliminated engine oil contamination and prevents potential leakages

Conclusion

By integrating the SwitchOn DeepInspect® system, our customer has taken a significant step forward in ensuring excellence in manufacturing. The result is a highly efficient, automated inspection process that upholds our customer’s commitment to quality, innovation, and customer satisfaction

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.