AI-Powered Vision System for Battery Pack Surface Defect Detection

DeepInspect® – EV battery pack quality inspection software powered by AI

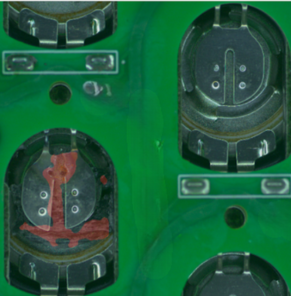

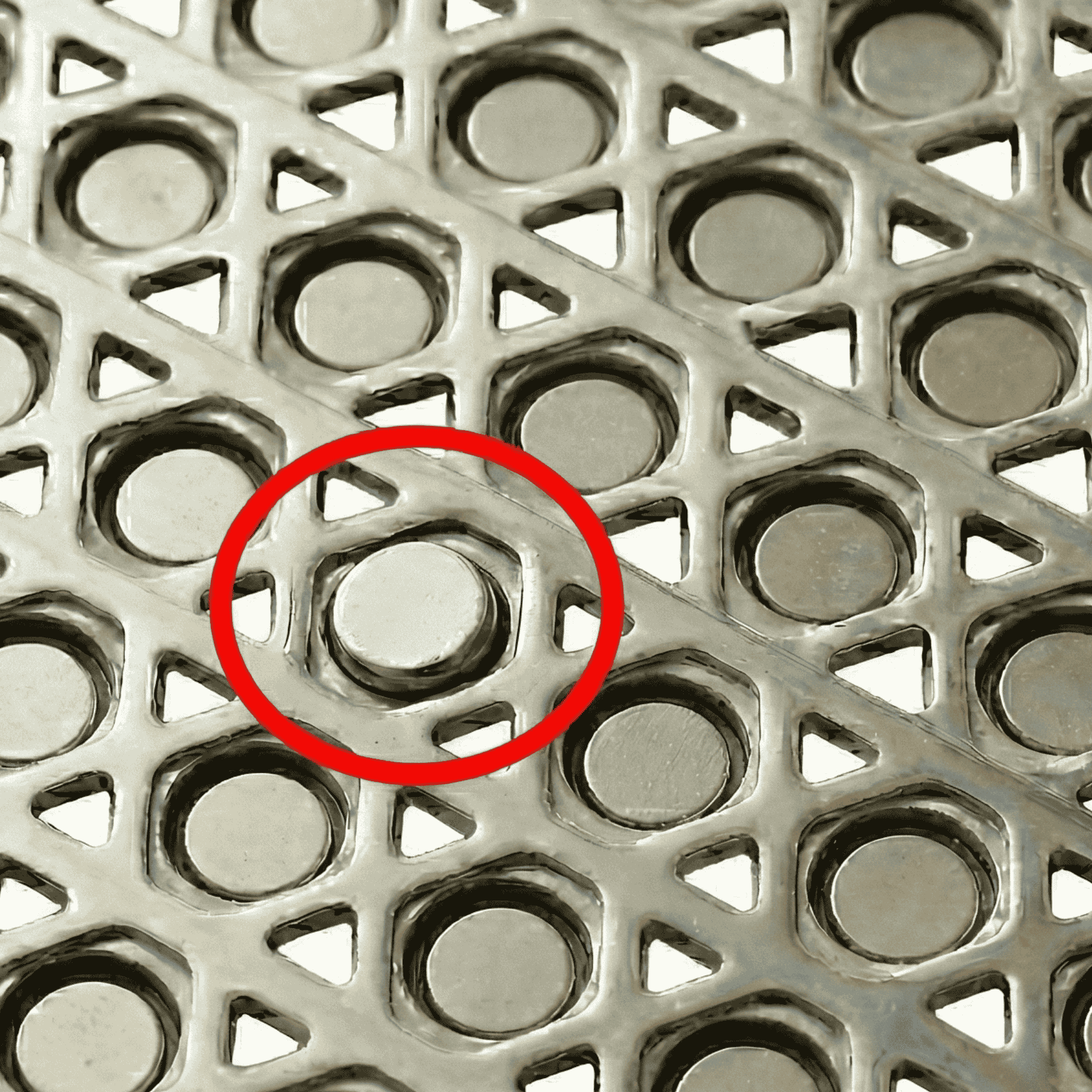

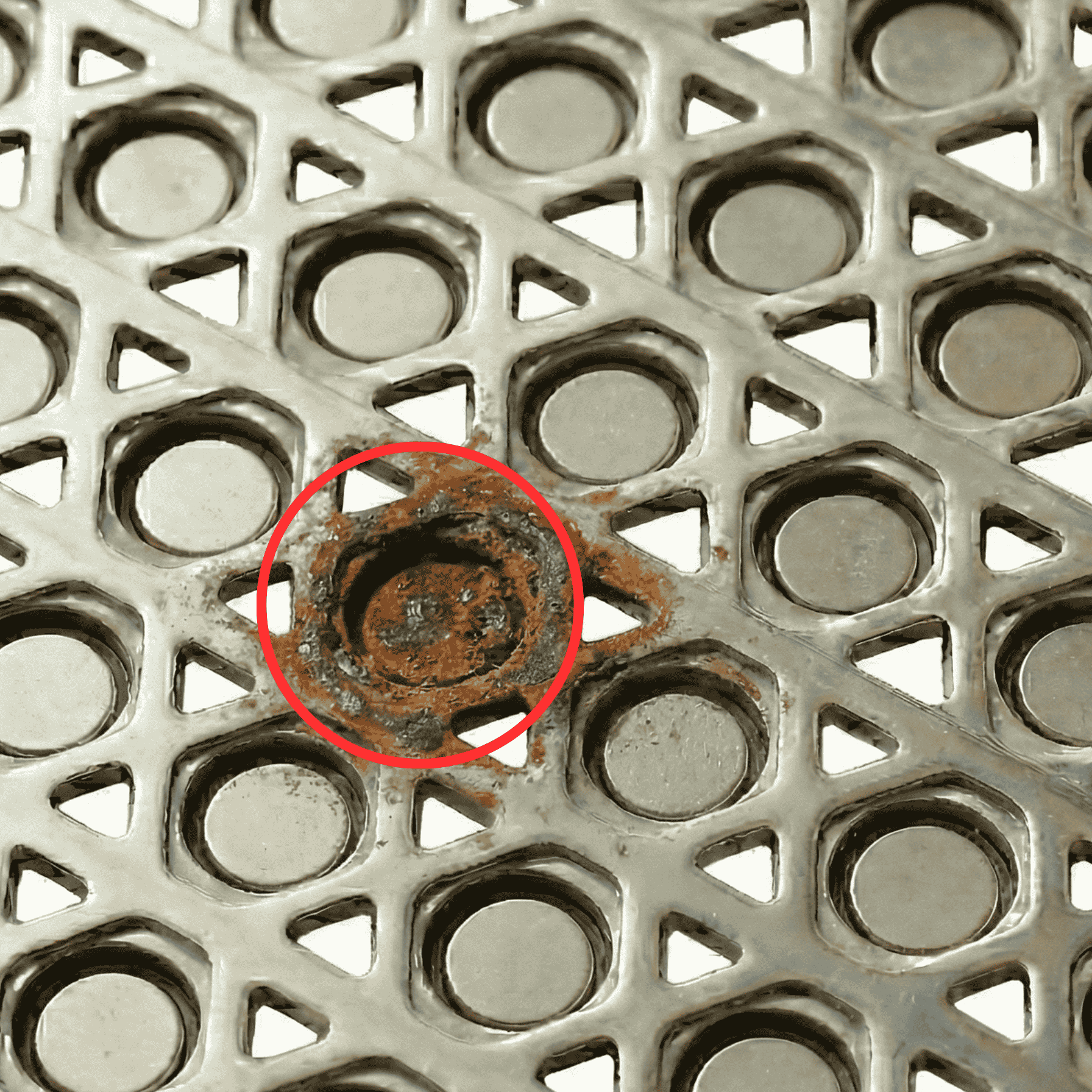

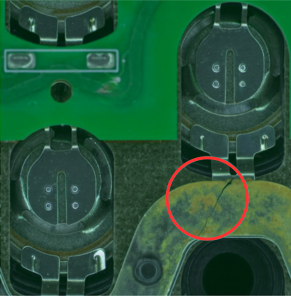

Battery pack manufacturing demands extreme precision. Even a single battery pack surface defect, such as a scratch, dent, weld defect, or contamination on a cell, module, or EV battery pack, can lead to performance loss, safety risks, or thermal instability. Traditional rule-based battery pack inspection systems struggle with this complexity — especially when defects are tiny, inconsistent, or visually subtle.

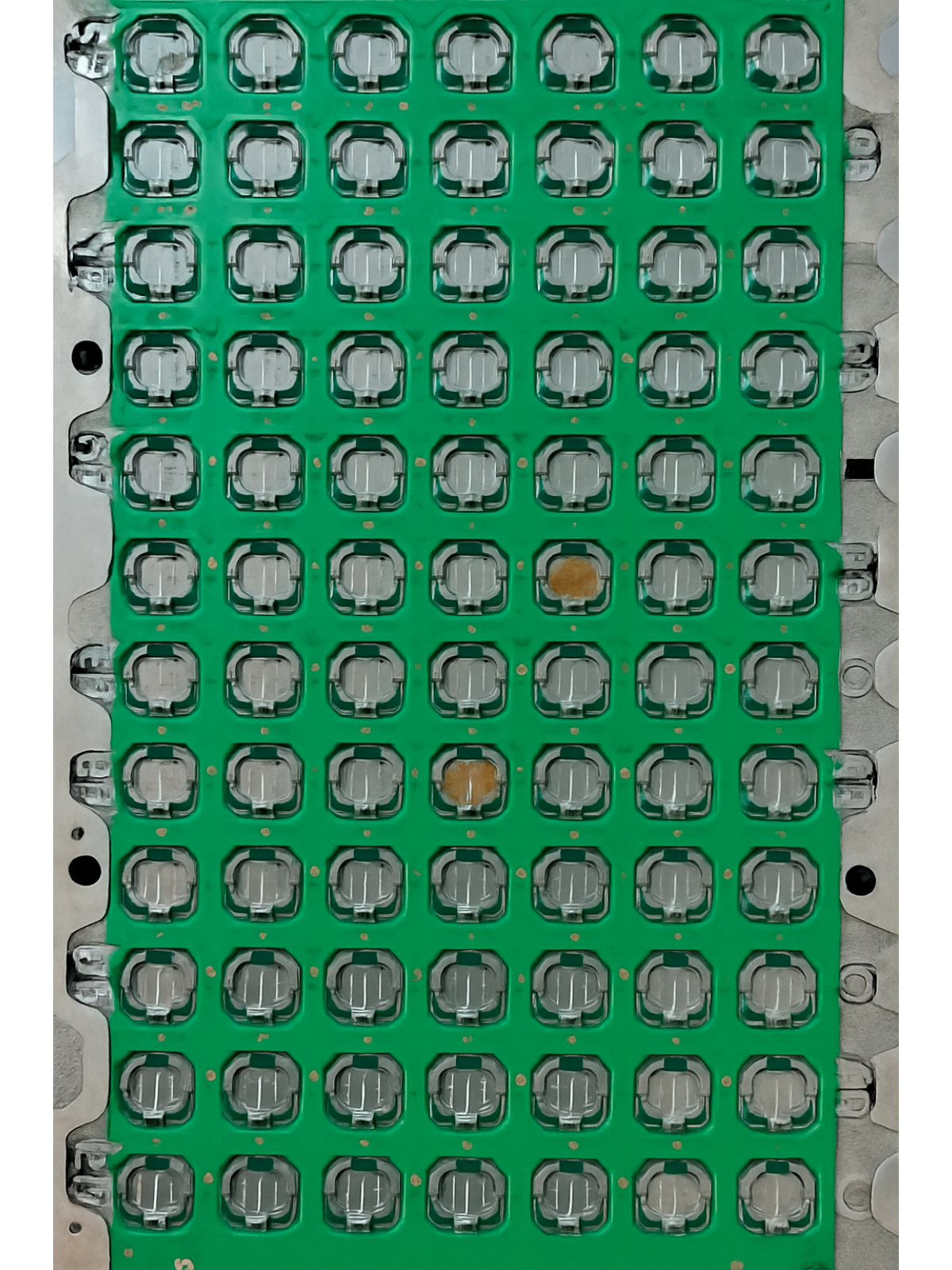

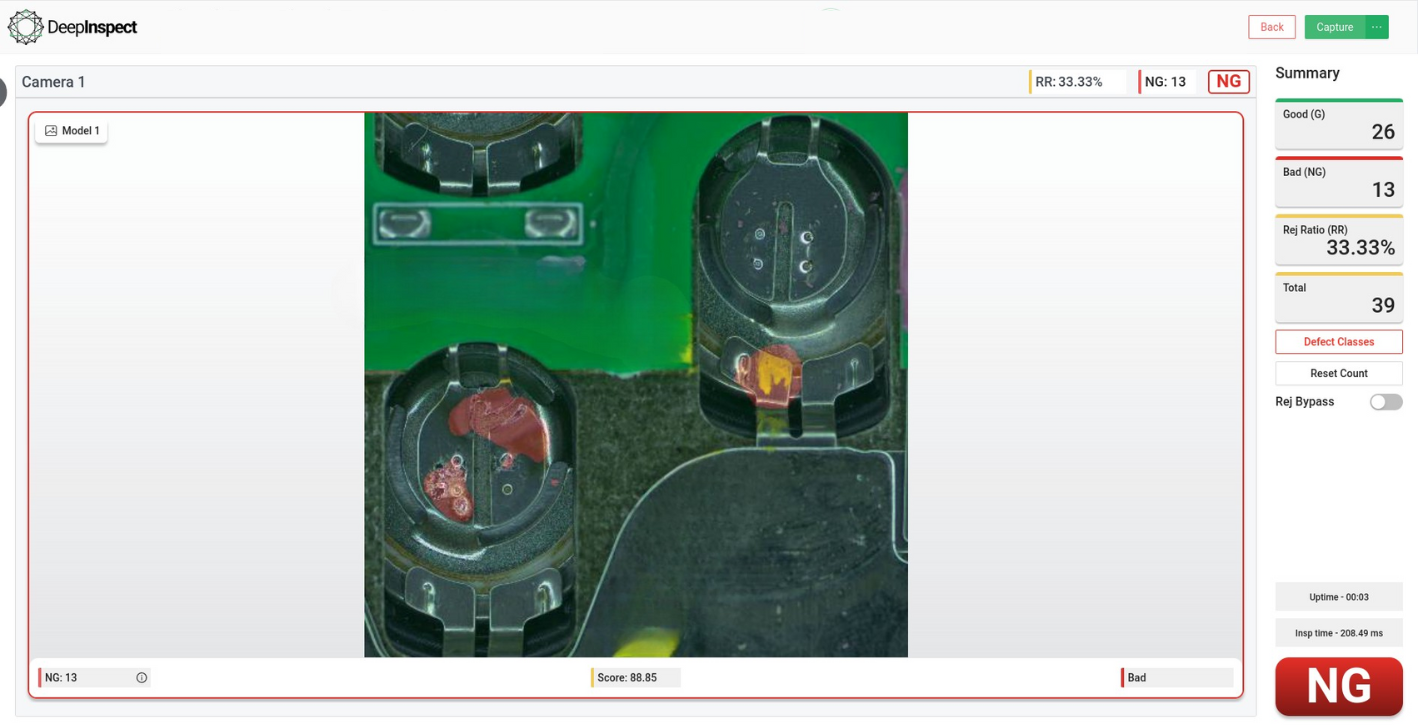

DeepInspect® transforms battery pack visual inspection with advanced AI-powered battery pack inspection, purpose-built for high-speed EV battery production lines. DeepInspect® uses cutting-edge deep learning battery defect detection and anomaly detection models to automatically identify surface defects in battery packs, including issues on battery cells, modules, BUS bars, casings, connectors, and fully assembled packs — all in real time.

It learns the natural variation of lithium-ion battery pack surfaces with <200 good images, enabling accurate detection of EV battery defects even when they are rare, unpredictable, or extremely subtle.

USECASE

Defects Detected by DeepInspect®

DeepInspect® detects all surface and dimensional defects, such as:

Scratches, dents, depressions, and even the most subtle burrs are effortlessly identified by DeepInspect

Wrong diameter, Incorrect pitch, Length variation, Wrong orientation, Double feed or overlapping pieces

Deformed head, Damaged drive profile, Off-center head, Irregular head height, etc.

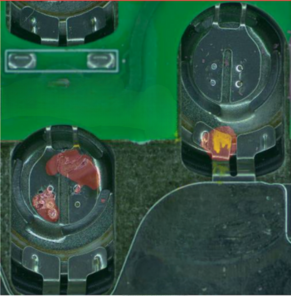

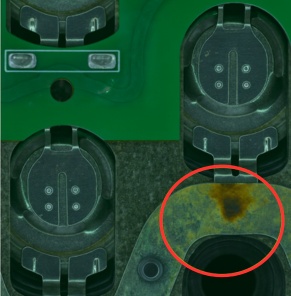

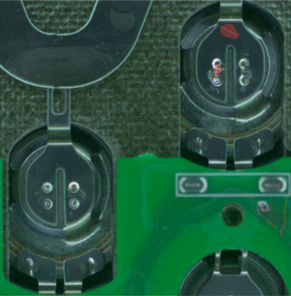

Burrs, Scratches, Surface dents, Cracks, Rust, corrosion, oxidation, cuts, damages, etc.

AI- Powered surface defect detection in EV battery packs & modules

Weld Splatter

Discoloration

Scratch

Foriegn Particles

Component Misalignment

Rust

Cracks

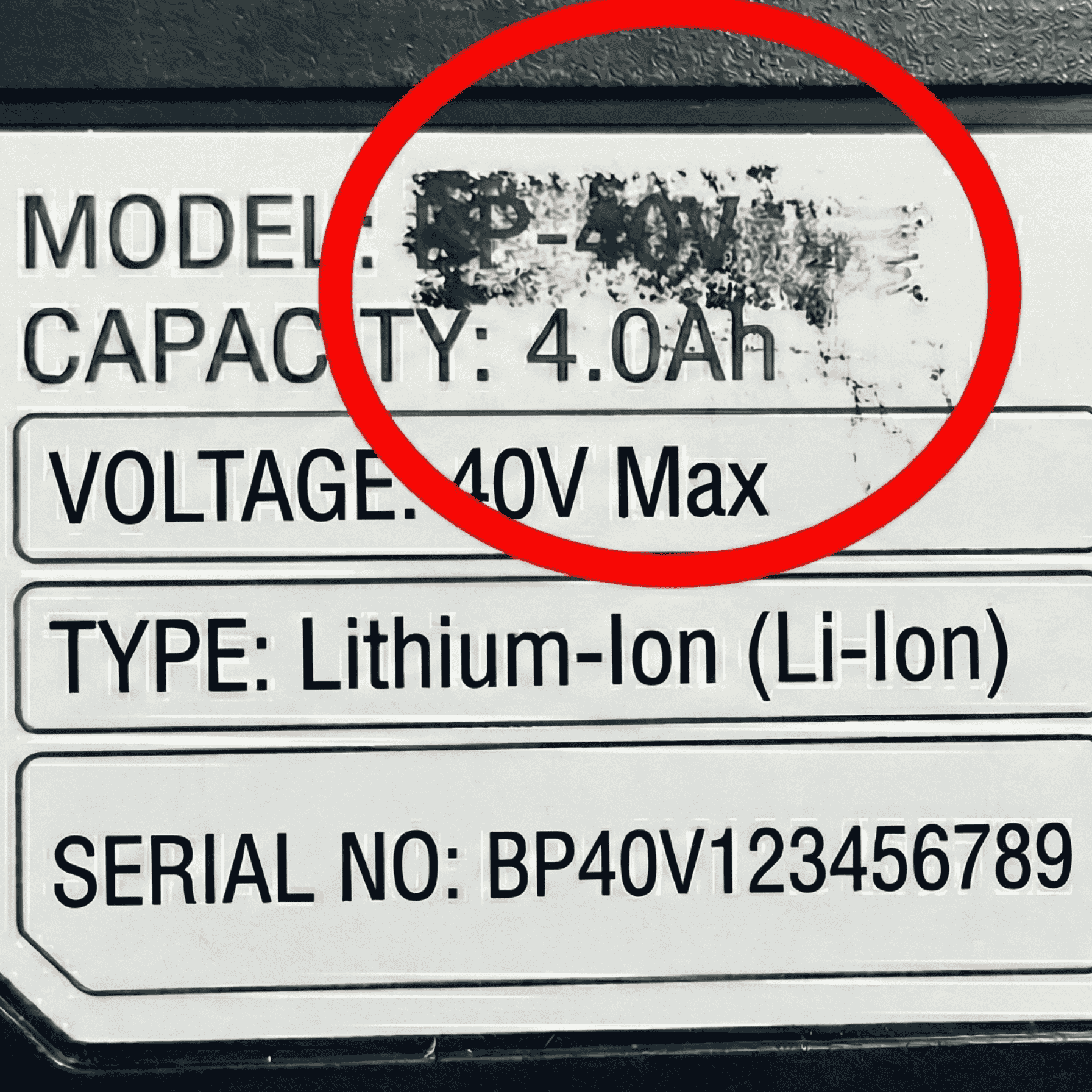

Label Defects

DeepInspect®- Battery module inline inspection software

The best AI system for battery pack inspection, offering unmatched precision, repeatability, and real-time performance

Catch defects early and move toward Zero-Defect EV battery production

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

Non-contact inspection for Lithium battery packs

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in machine vision for battery pack QC software?

Book a free demo!

Inquiry Form

DeepInspect AI-powered system for battery pack inspection uses deep learning and machine vision to detect surface defects, weld issues, contamination, and assembly errors in EV battery packs with high accuracy.

Surface defect detection in EV battery packs helps identify scratches, dents, weld splatter, and burrs early to prevent performance loss, safety risks, or thermal instability.

Yes. DeepInspect® performs completely non-contact inspection for lithium battery packs using high-resolution imaging and AI-based defect detection.

Absolutely. DeepInspect® can inspect cylindrical cells, prismatic cells, modules, bus bars, casings, and assembled EV battery packs.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect® requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect® uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

A line demo for DeepInspect®’s inspection system can be conducted within a day

Because it combines deep learning, real-time inspection, non-contact detection, and high repeatability—making it one of the most advanced and scalable solutions for EV battery pack surface defect detection.