AI Powered Biscuit Inspection Leveraging DeepInspect

AI Powered Biscuit Inspection

Related Articles

Introduction

Biscuit manufacturers often face many customer complaints and compliance issues due to the product manufacturing issues. These unidentified defects can significantly impact their brand reputation, and fines. Additionally, any presence of foreign particles can compromise hygiene standards, leading to severe consequences like customer dissatisfaction, product returns,etc. ultimately affecting the bottom line.

To address these challenges, leading manufacturers are now using DeepInspect®- an AI powered biscuit inspection system.

The Capabilities of DeepInspect® in Biscuit Inspection

Manufacturers can inspect biscuits of any size or shape, with standard dimensions being 80 x 30 mm. Furthermore, using DeepInspect® means that the waste caused by such a system is only limited to less than 0.5% which means adoption can be immediate, ensuring reliability and accuracy. Let us explore the inspection capabilities of DeepInspect:

DeepInspect®: AI-Powered Visual Quality Inspection Software for Biscuit Manufacturers

Inpack Inspection

Manufacturers can leverage DeepInspect in detecting a wide range of defects including

Biscuit cracks inspection

Inspect foreign particle presence in biscuits

Biscuit logo inconsistencies inspection

Half-baked biscuit inspection

Visible or oozing cream inspection

Extra biscuits sticking together

Biscuit holes inspection etc.

Outpack Inspection

Manufacturers can ensure comprehensive packaging inspection using DeepInspect by detecting

Surface defects

Packaging and label defects

How AI powered biscuit inspection works?

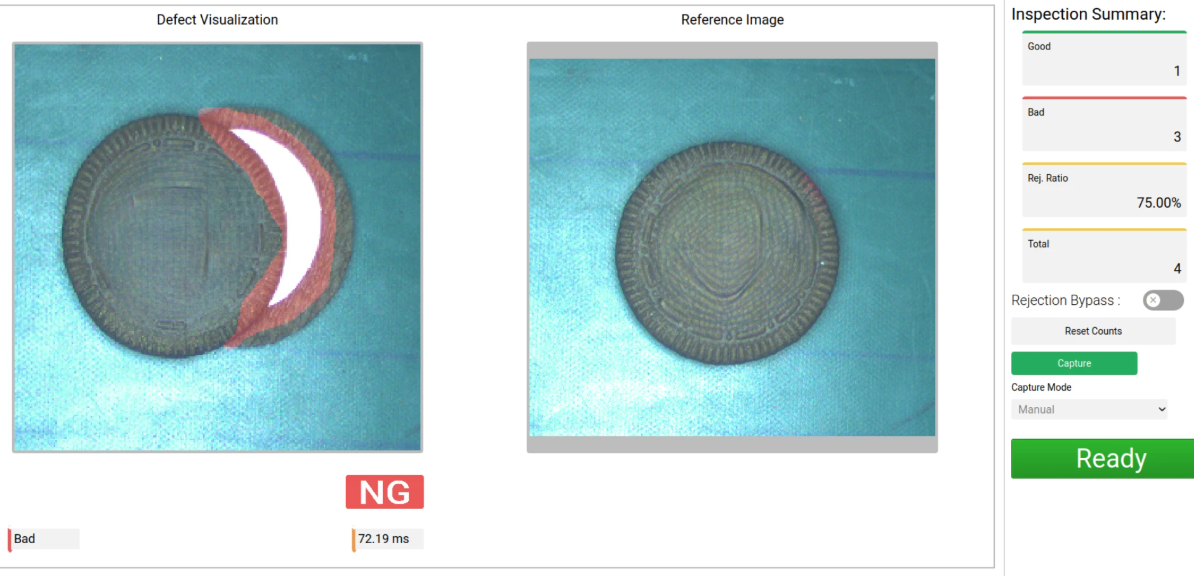

The AI-powered visual inspection setup involves placing a camera from the top for each line, ensuring thorough monitoring at a line speed of 180 to 200 parts per minute. The setup includes an industrial camera and lighting, with DeepInspect software at the heart of the system. The AI models within DeepInspect software can be trained in under 45 minutes using fewer than 200 good biscuit images.

When a surface defect is detected in a particular biscuit, the system triggers the rejection mechanism. The pusher mechanism then pushes the defective biscuit from the conveyor tray, maintaining a seamless production flow. Also, the defect classification feature in the DeepInspect software enables users to pinpoint the specific defect that caused a biscuit to be rejected.

Conclusion:

Biscuit manufacturers can effectively run their production lines by eliminating the requirement for three personnel and optimizing labor costs. With a packaging inspection speed of 180 to 200 ppm, DeepInspect guarantees that only the best quality biscuits reach the market. This not only enhances customer satisfaction but also strengthens brand reputation, ensuring that your products consistently meet and exceed export quality standards.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Learn More?

Download the full use case below!