AI Vision Inspection for Brake Pads- Automotive

DeepInspect- AI-powered automotive brake pad quality control software

Ensure flawless brake pad quality with AI-powered visual inspection using DeepInspect. Our system detects critical defects like cracks, edge chipping, rust, uneven thickness, surface contamination, etc.—all in real time with over 99.5% accuracy. DeepInspect enables automated brake pad inspection without relying on manual checks, significantly reducing human intervention and errors. With just 200 good samples needed for training, the system quickly adapts to new brake pad SKUs, performing inline inspections at high speeds. Whether it’s dimensional inspection, surface defect detection, or identifying delamination and material flash, DeepInspect ensures consistent quality across every unit. Trusted by top automotive manufacturers, our solution integrates seamlessly into existing lines, offering real-time analytics, quality reports, and low false positives—all in a compact, robust setup. Upgrade to DeepInspect and transform your brake pad quality control

APPLICATION

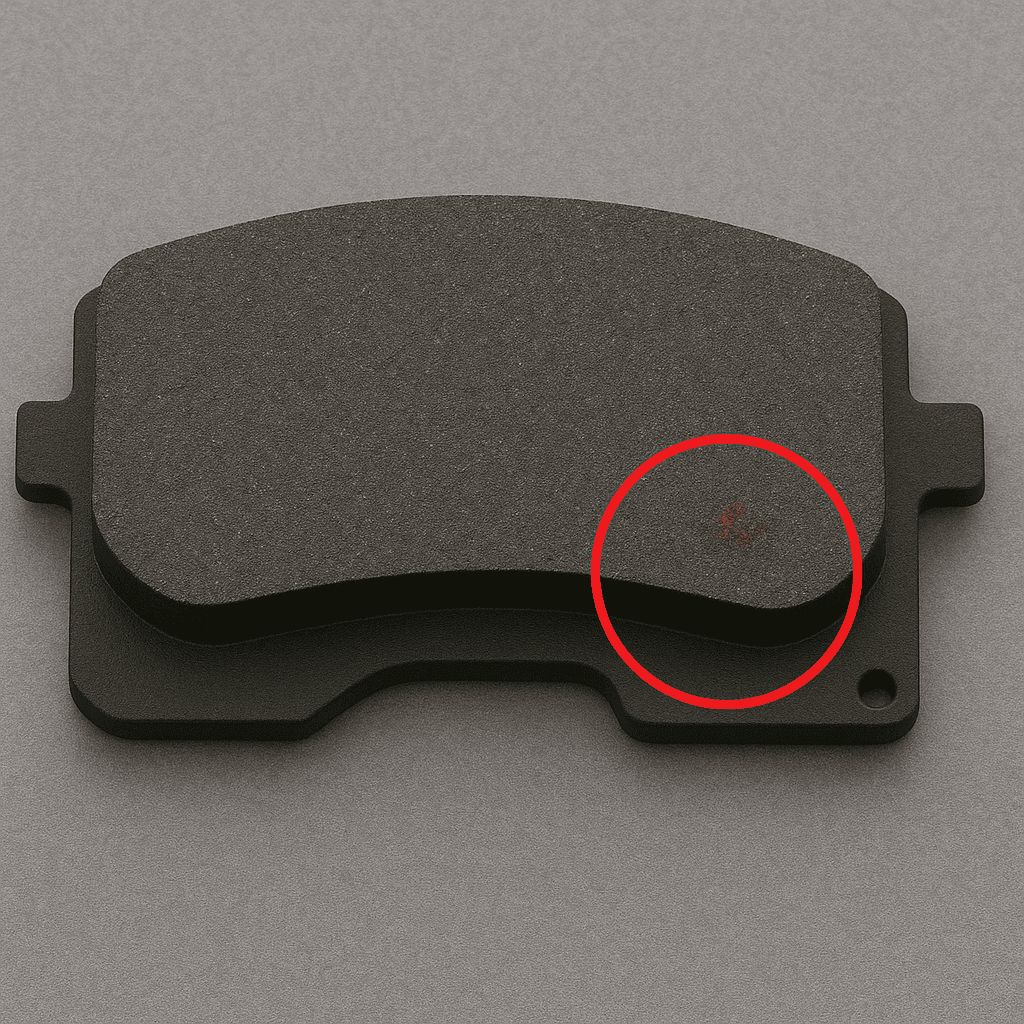

Detect surface defects like scratches on pad surface using AI-based inspection

Detect defects like dents formed during pressing or manual part handling

Detect defects like burrs from poor machining or improper trimming operations

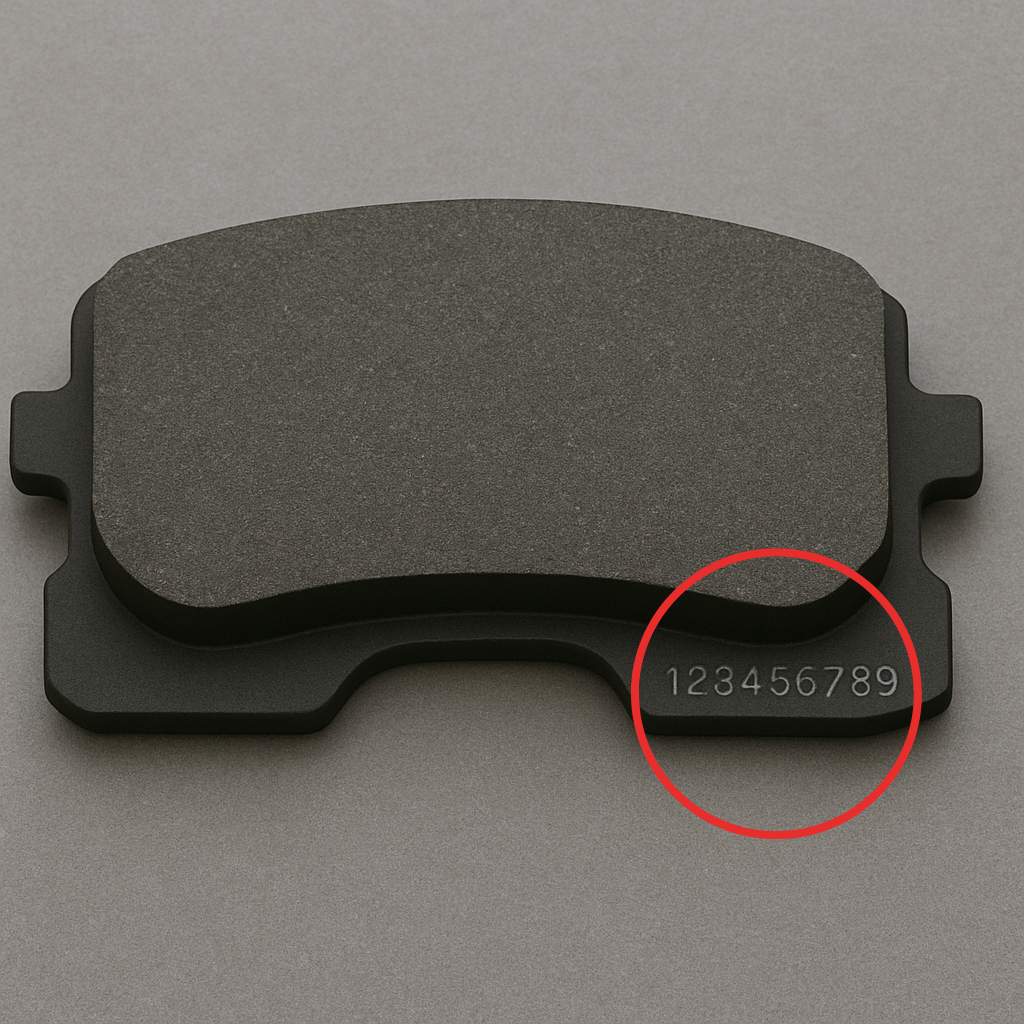

Detect OCV/OCR defects like missing, incorrect, or blurred optical character markings

Impact

DeepInspect transforms brake pad inspection by eliminating manual errors, reducing labor costs, and ensuring consistent quality. With 99.5% accuracy, it detects defects like cracks, chipping, and rust in real time—boosting efficiency, traceability, and confidence in every unit shipped.

Brake Pad Quality Inspection with 99.5% Accuracy

Brake Pad Scratches

Brake Pad Dents

Brake Pad Rust

OCV/ OCR

Interested in Streamlining Brake Pad quality control ?

Drop us a line or shoot us an email

Inquiry Form

Brake pad defect detection is the process of identifying surface issues like cracks, edge chipping, burrs, or dents using automated visual inspection systems

AI brake pad inspection systems powered by DeepInspect use industrial cameras and deep learning algorithms to analyze images in real-time and flag quality defects with over 99.5% accuracy

Commonly detected defects include surface scratches, cracks, burrs, uneven thickness, rust, and missing or blurred OCR markings on the brake pad.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

OCR (Optical Character Recognition) verifies engraved codes or serial numbers to ensure traceability, batch integrity, and compliance with OEM standards.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for defect detection

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection system

A line demo for DeepInspect system can be conducted within a day, showcasing its fast implementation and ease of use