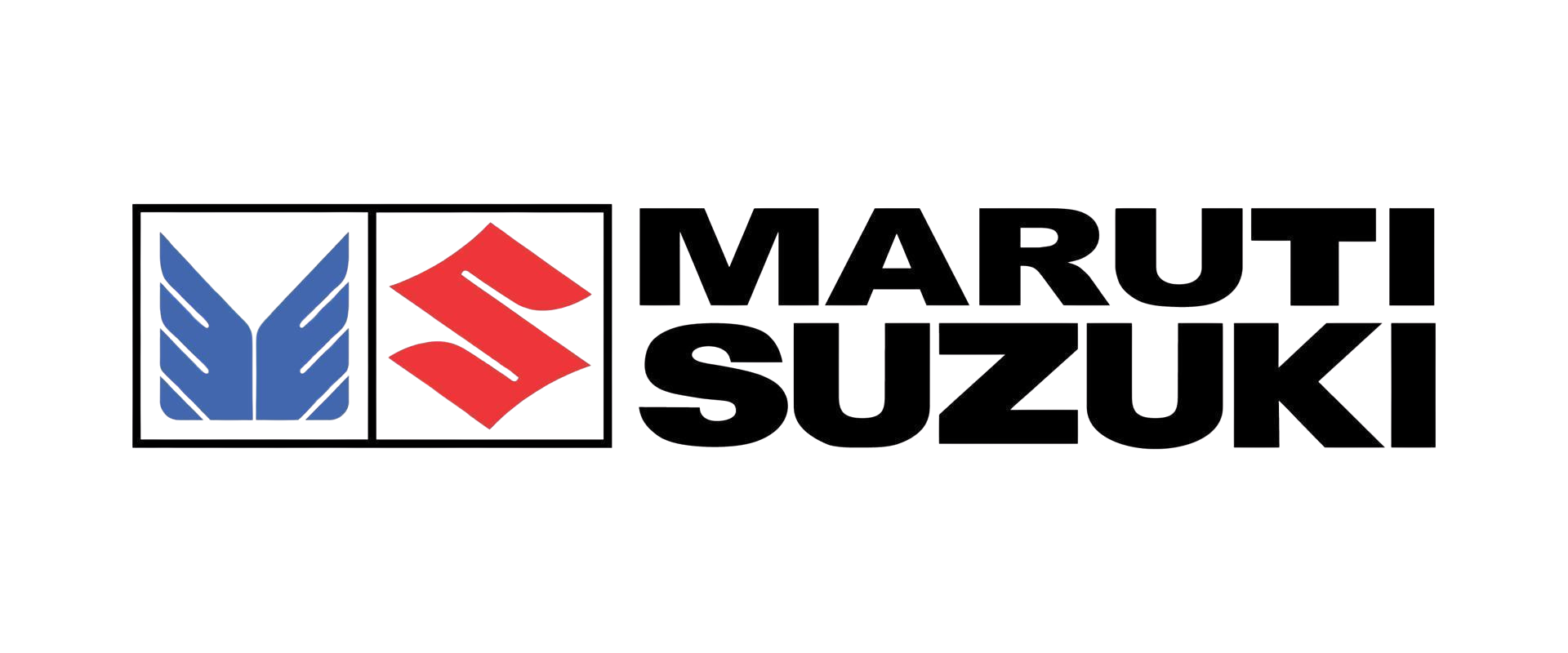

A Leap Forward- Introducing Analytics in DeepInspect Pro

Introducing Analytics in DeepInspect Pro

Related Articles

At SwitchOn, we are constantly pushing the boundaries of innovation to meet the evolving needs of Industry 4.0. DeepInspect has always been a powerful tool for ensuring the highest accuracy in visual quality inspection. With the introduction of analytics, we are taking a significant leap forward in enabling smarter, data-driven decisions.

Here's how our new analytics feature can transform your inspection processes:

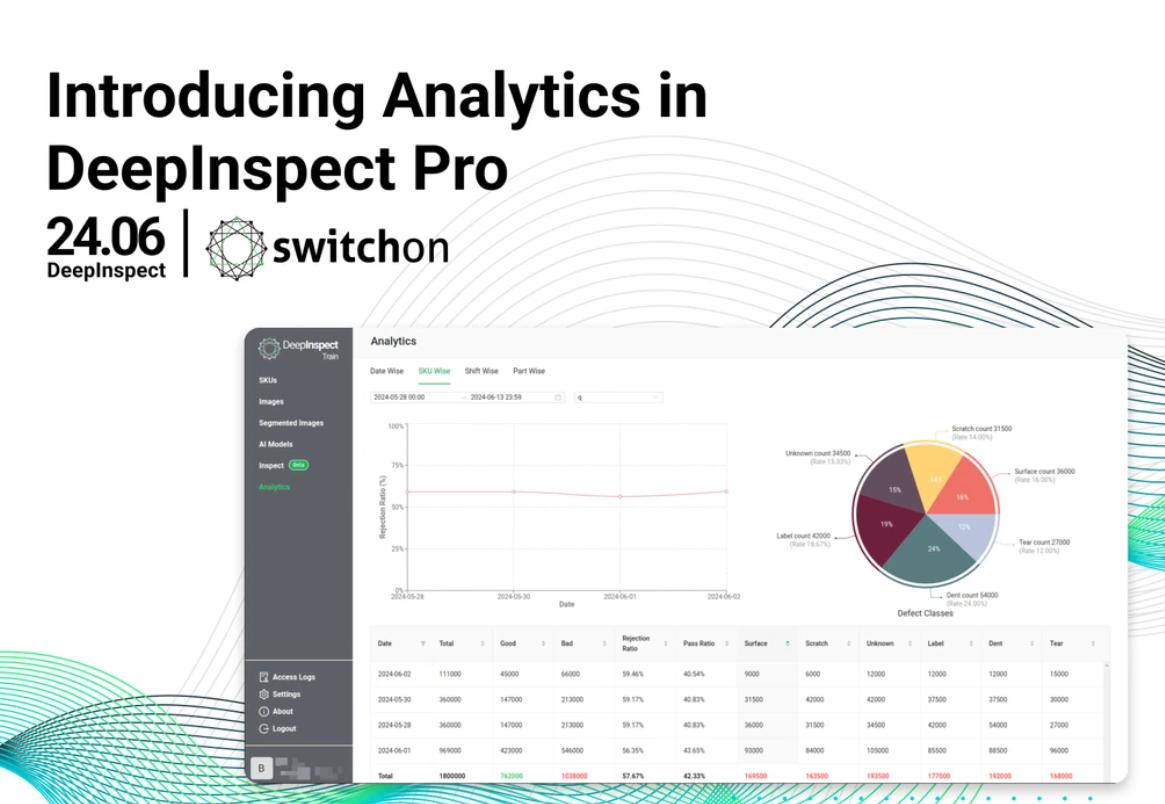

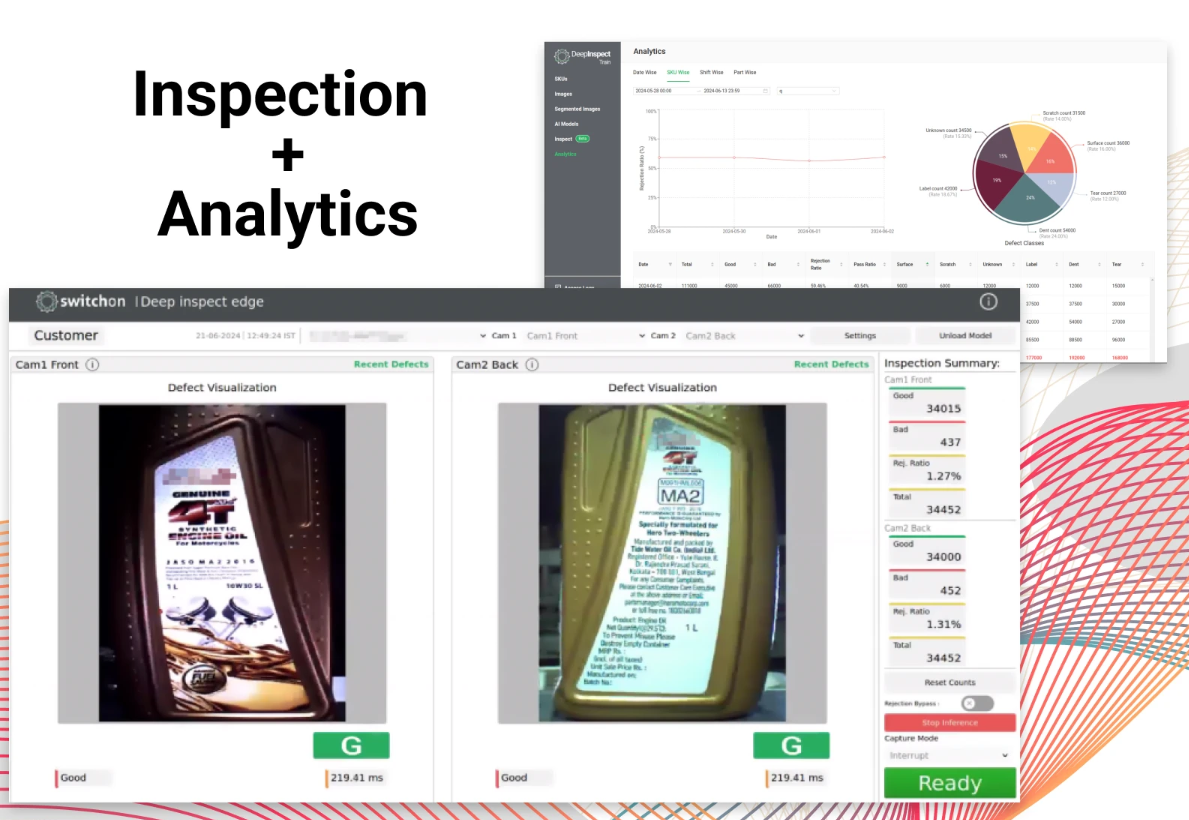

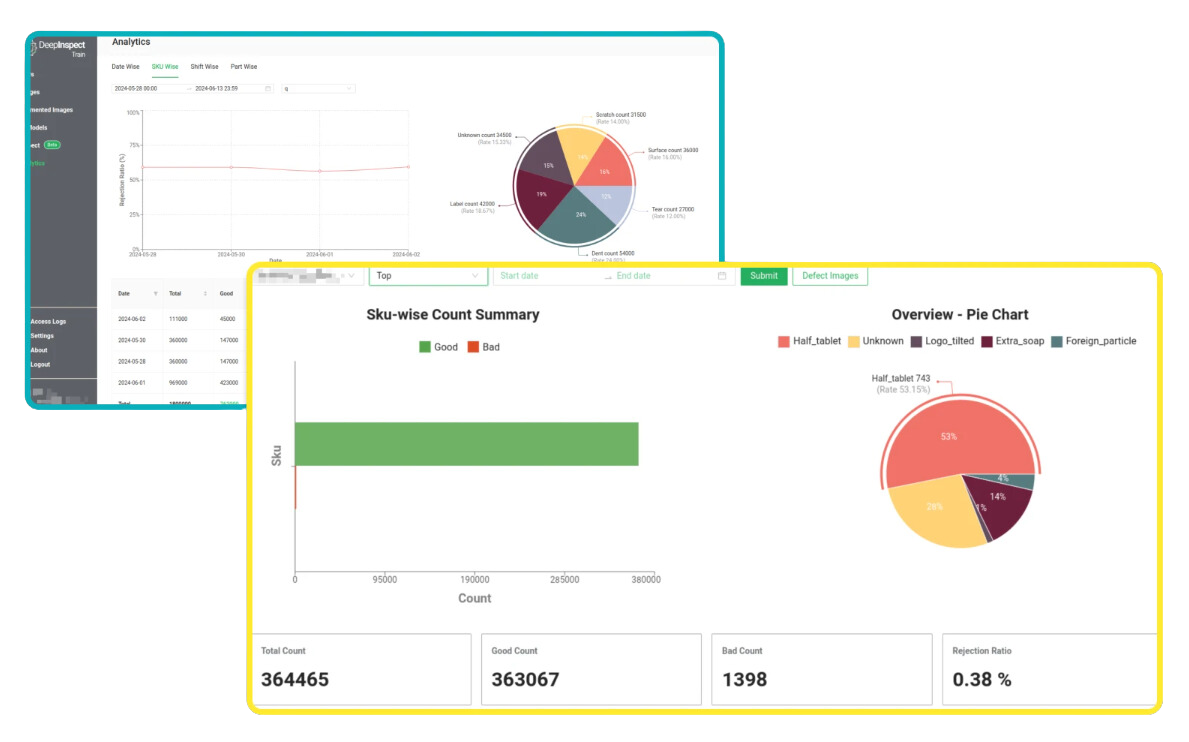

Understanding production patterns and trends is crucial for quality improvement. DeepInspect Pro’s analytics allow you to monitor production volumes at hourly,daily, weekly and monthly levels. Track defect ratios, and evaluate pass ratios to ensure consistently high standards.

Not all products are created equal, and their inspection results can vary significantly. With our analytics, you can compare the performance of different SKUs to identify which products are performing well and which need attention. Use these insights to target specific SKUs for process improvements, thereby enhancing overall product quality and efficiency.

Understanding the root cause of defects is essential for continuous improvement. DeepInspect Pro’s analytics provide powerful tools to Track defects back to their source, whether it is a specific machine, process, or raw material batch, to prevent recurrence.

Analytics Specification:

Image, Result and Timestamp stored for all inspections at 1000+ PPM

Camera level data for multiple camera setups.

Access up to 1 year of data on the edge without any internet or cloud

Configurable to store all inspected G and NG data.

Compare data from multiple lines, plants, and geographies with DeepInspect Cloud*

Empowering Industry 4.0 with DeepInspect Pro

Integrating analytics into DeepInspect Pro marks a significant milestone in our mission to support Industry 4.0. By providing deeper insights and actionable intelligence, we empower manufacturers to not only detect issues but also predict and prevent them. This proactive approach leads to higher-quality products, reduced downtime, and a more efficient production process.

Stay tuned for more updates as we continue to innovate and bring you the best in inspection technology. Welcome to the new era of intelligent inspection with DeepInspect Pro.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.