Revolutionizing Gasket Quality With DeepInspect

Revolutionizing Gasket Quality With DeepInspect

Related Articles

Introduction

Gaskets are critical components used to seal the space between two mating surfaces, preventing leaks and ensuring optimal functionality in automotive, industrial, and other applications. Their reliability directly impacts product performance, safety, and durability. Even minor defects in gaskets, such as surface irregularities or misaligned holes, can lead to significant issues, including system failures, inefficiencies, and customer dissatisfaction. Traditional inspection methods often fall short in detecting these defects effectively, creating challenges for manufacturers.

Challenges- Why Traditional Vision Systems Struggle with Gasket Inspections?

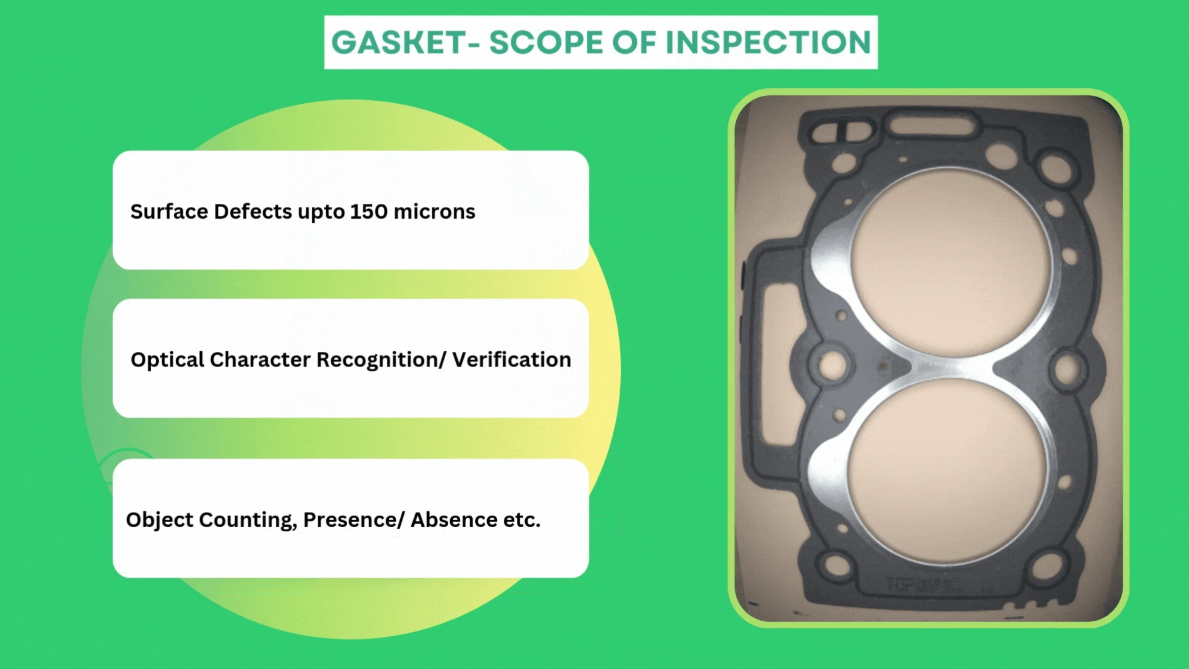

Surface defects, incorrect hole counts, and optical character inaccuracies in gaskets can lead to leaks, misalignments, and product failures, compromising durability and disrupting supply chains. Identifying these multiple defects traditionally requires separate cameras and setups, increasing complexity, setup time, and costs. Manufacturers have struggled with these systems, finding them inefficient, error-prone, and unable to meet the demands of modern production workflows.

DeepInspect- AI Powered Quality Inspection Software for Gasket Manufacturers

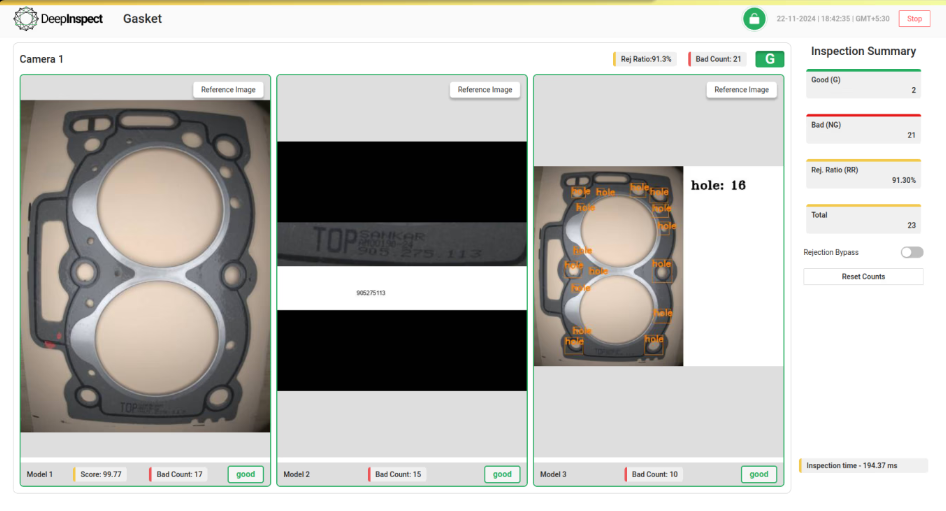

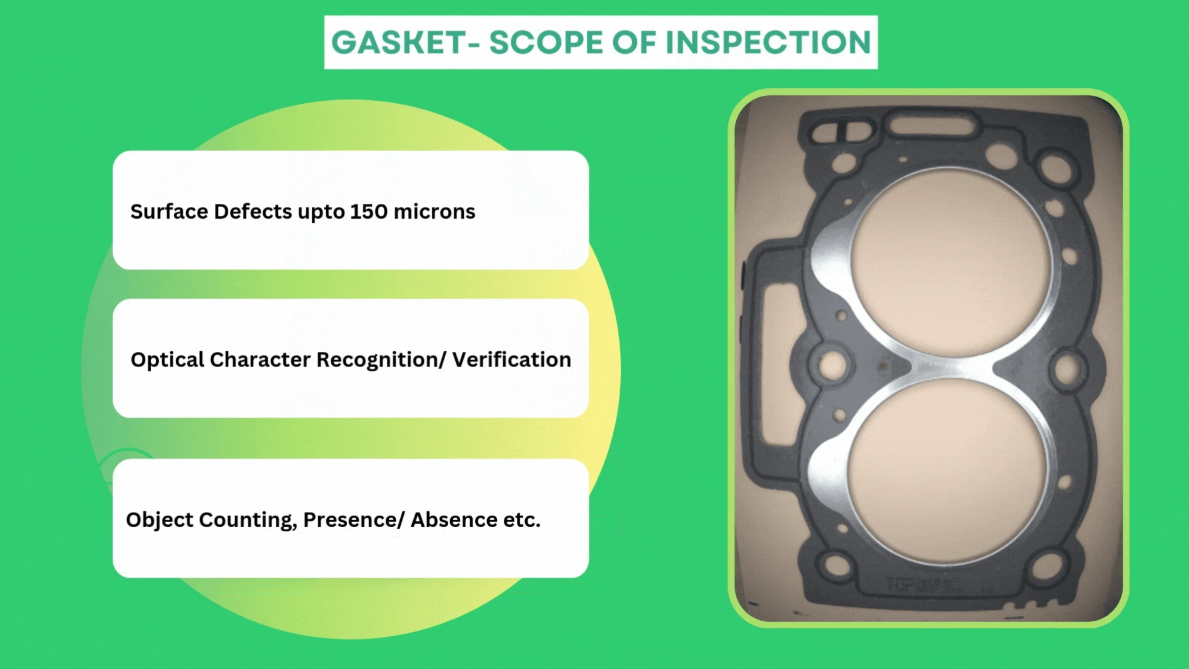

DeepInspect® revolutionizes gasket visual quality control by enabling manufacturers to train AI models with fewer than 200 good images in just ~45 minutes, significantly reducing setup time. Utilizing a single-camera system, DeepInspect performs multiple inspections simultaneously on a single product within a single field of view, streamlining operations and delivering exceptional precision. This efficient approach ensures faster setup, consistent quality, and optimized production workflows for gasket manufacturers.

Gasket Defects That can be identified in DeepInspect Single FOV, Multiple inspection

DeepInspect: Enabling Multiple Inspections in a Single Field of View

Using a single camera for multiple inspections, DeepInspect® eliminates the need for separate cameras and setups traditionally required for visual quality inspections. This approach significantly reduces inspection costs while addressing challenges like increased complexity and longer setup times. By performing multiple inspections within a single field of view, DeepInspect streamlines operations and enhances efficiency for manufacturers.

The Setup

DeepInspect 24.11

Industrial Controller (core- i5+GPU)

Industrial Machine Vision Lights

Allied vision Industrial Camera

Mitsubishi IO Module

Rejection System

Conclusion

DeepInspect ensures 99.5% accuracy in gasket visual quality inspections, leaving no room for errors while minimizing labor dependencies and enhancing operational efficiency. Contact us today to learn how we can streamline your operations and elevate your quality control processes.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Learn More?

Download the full use case below!