Gelatin Capsule Inspection Using DeepInspect

Gelatin Capsule Inspection Using DeepInspect

Related Articles

Introduction

In the pharmaceutical industry, ensuring quality control in the manufacturing of soft gelatin capsules is critical. However, manufacturers often face challenges such as shape deformation, air bubbles, leaks, discoloration, and other surface defects, which can compromise product quality and increase production waste. These issues often go undetected until large batches have already been produced, risking potential recalls and regulatory issues.

The Challenges of Defects on Soft Gelatin Capsules

Defects in soft gelatin capsules not only affect quality but also pose serious risks for consumers. Some of the key challenges manufacturers faces are:

Surface Defects

Capsules with visible issues like deformations or discoloration can lead to costly recalls, damage to brand reputation, and increased operational costs due to non-compliance with regulatory standards.

Dosage Inconsistencies

Air bubbles and leaks inside soft gelatin capsules can disrupt dosage consistency, impacting the stability and effectiveness of the medication. These issues ultimately increase rejection rates and production costs.

Reduced Shelf Life

Leaks or improper sealing expose the contents to moisture, air, and contaminants, significantly shortening the capsules' shelf life and efficacy.

Ineffective Treatment

When active ingredients degrade due to exposure, medications lose potency, leading to ineffective treatment and compromised customer trust.

DeepInspect : FDA CFR 21 P 11 Complaint Software for Gelatin Capsule Manufacturers

Key Components of the DeepInspect Setup

DeepInspect Software: The AI-powered system at the heart of inspection.

Industrial Controller: Equipped with an i5 processor and GPU for fast data processing.

Industrial Vision Lights & Camera: Ensure high-quality images for precise defect detection.

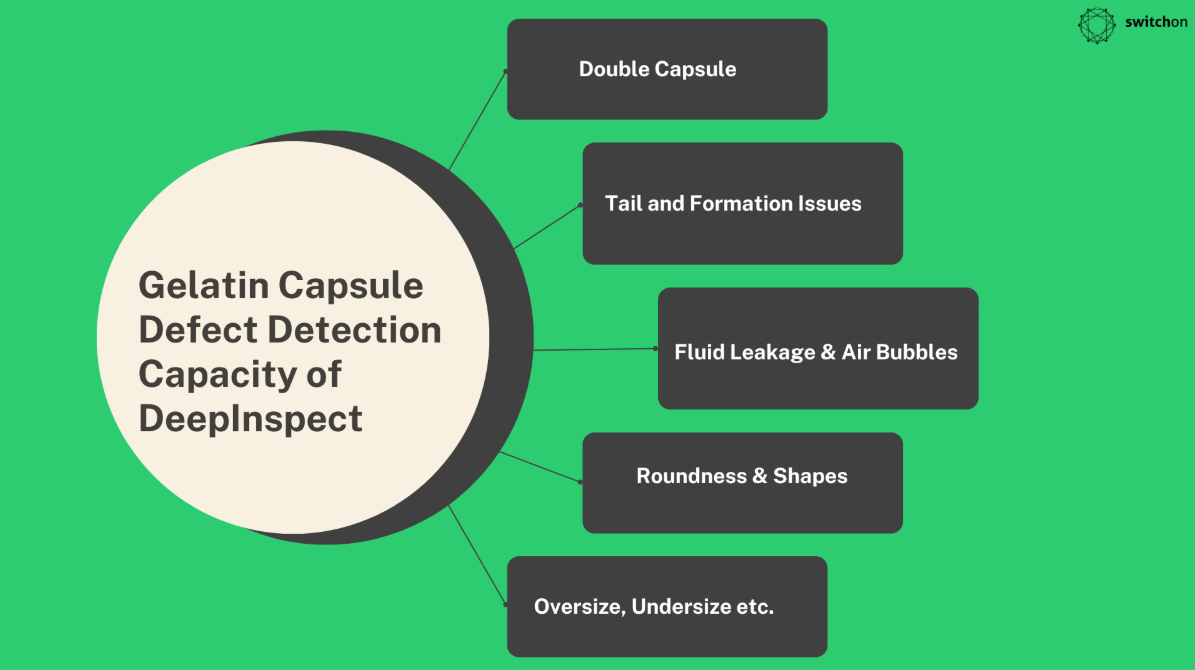

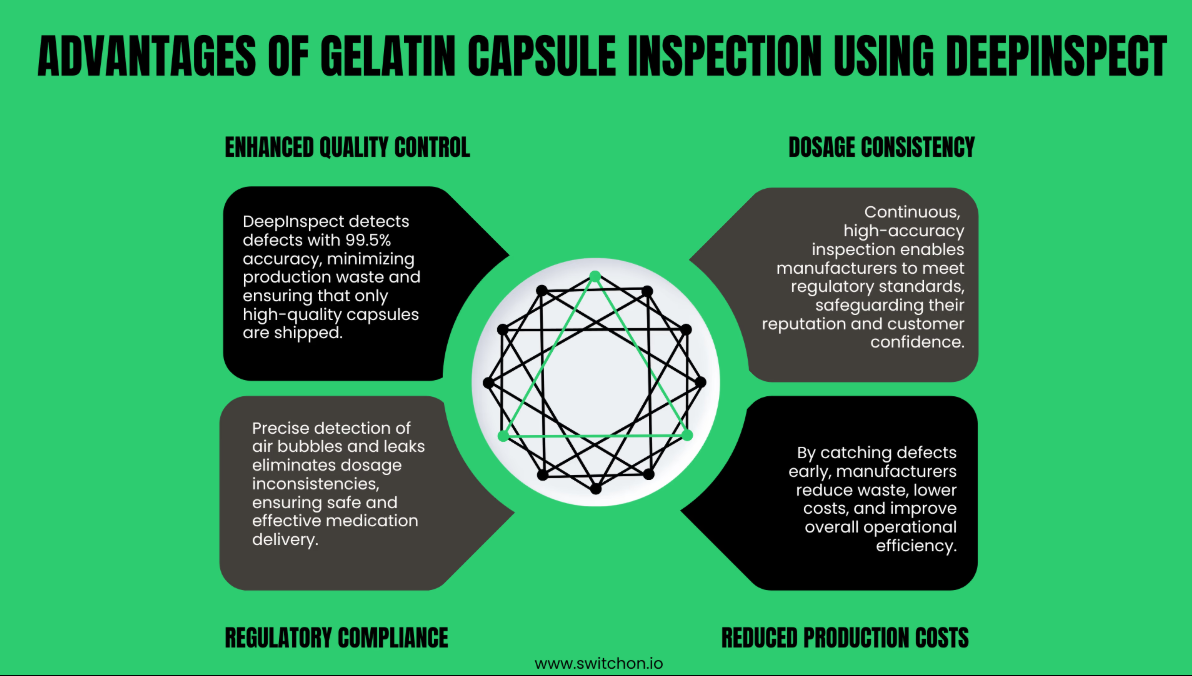

DeepInspect is an AI-powered visual quality inspection software designed to help Gelatin capsule manufacturers identify a wide range of surface defects with exceptional precision. Utilizing advanced machine learning algorithms, DeepInspect helps achieve a remarkable 99.5% accuracy in defect detection, elevating quality control processes and ensuring product consistency.

How Does AI Powered Gelatin Capsule Inspection Using DeepInspect Works?

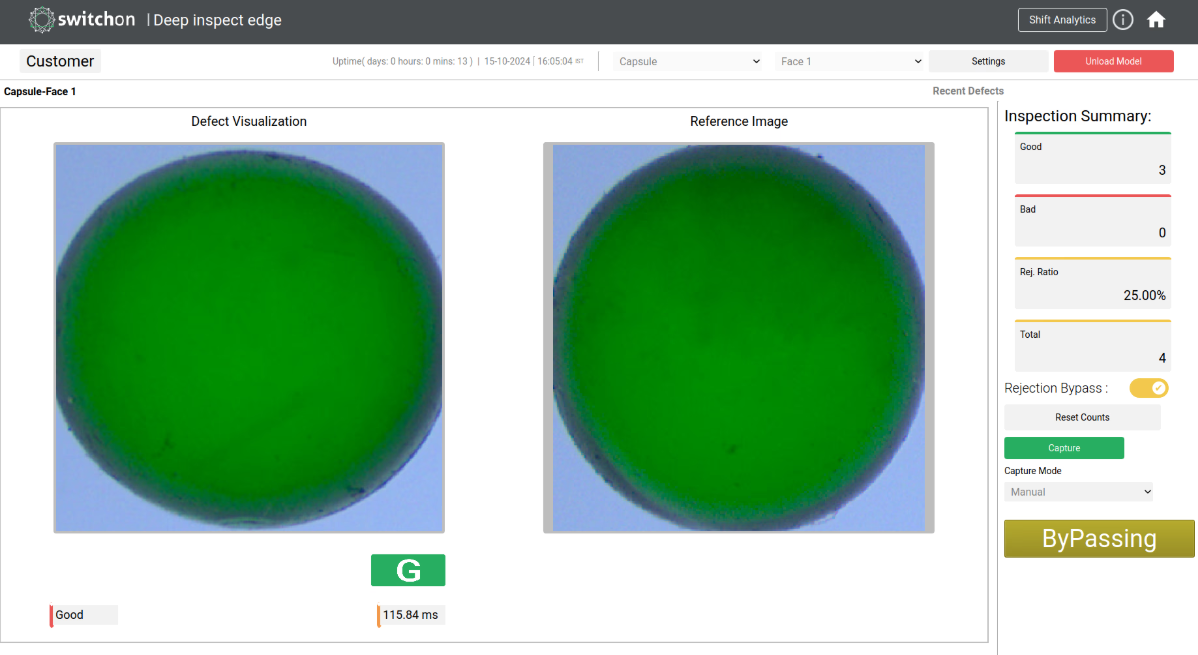

The inspection system positions an industrial camera above the capsule conveyor, while lighting is placed below the transparent conveyor belt to illuminate the capsules, ensuring clear image capture. This setup can process 2,000 capsules per minute, achieving an effective throughput of 1.2 lakh capsules per hour, ensuring 100% inspection at high speed for continuous real-time monitoring.

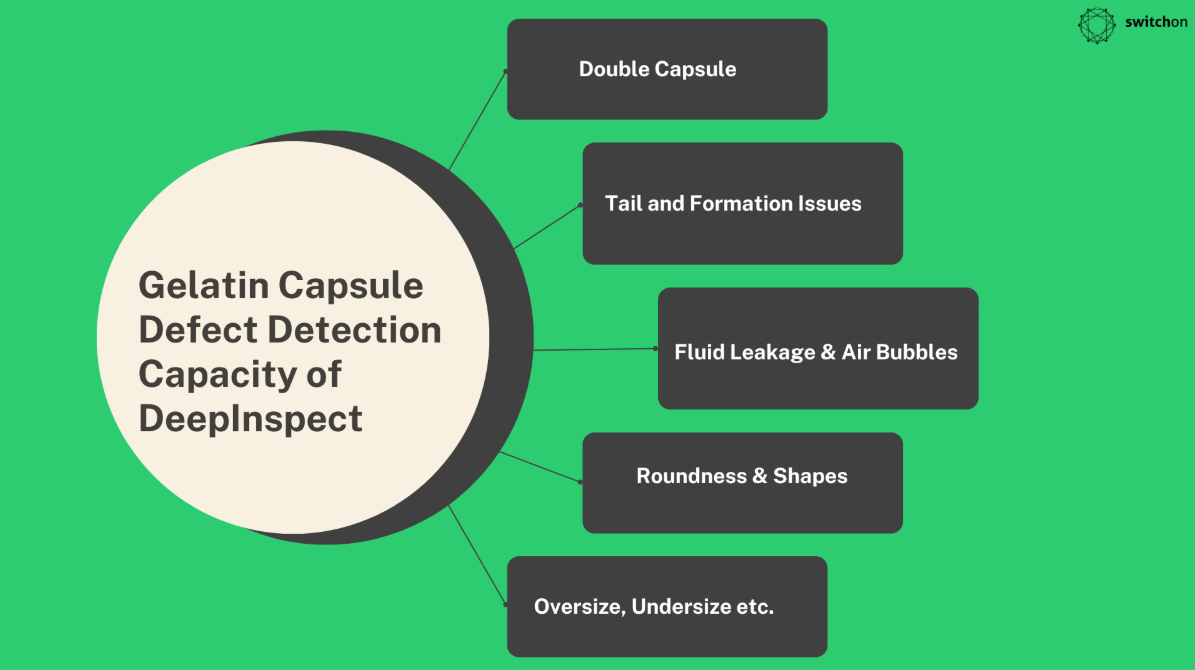

As the capsules move along a slanted conveyor while the DeepInspect system monitors for defects such as air bubbles, double capsules, black spots, satellites, and shape deformations with unparalleled 99.5% accuracy. When defects exceed a preset threshold, an alert is triggered, enabling immediate corrective action.

Impact of DeepInspect on Gelatin Capsule Manufacturing Quality and Efficiency

By implementing DeepInspect, soft gelatin capsule manufacturers can proactively detect production losses and ensure only high-quality capsules reach the market.

Conclusion:

SwitchOn’s DeepInspect system is a breakthrough for soft gelatin capsule manufacturers, bringing unprecedented accuracy and efficiency to the machine vision inspection for pharma. With its ability to detect defects in real-time and reduce false positives to just 0.5%, DeepInspect ensures that only the highest-quality capsules reach the market. For manufacturers, this means enhanced product safety, regulatory compliance, and greater customer satisfaction – all while minimizing waste and reducing costs.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Learn More?

Download the use case below!