AI-Powered Empty Glass Bottle Inspection

AI-Powered Glass Bottle Inspection

Related Articles

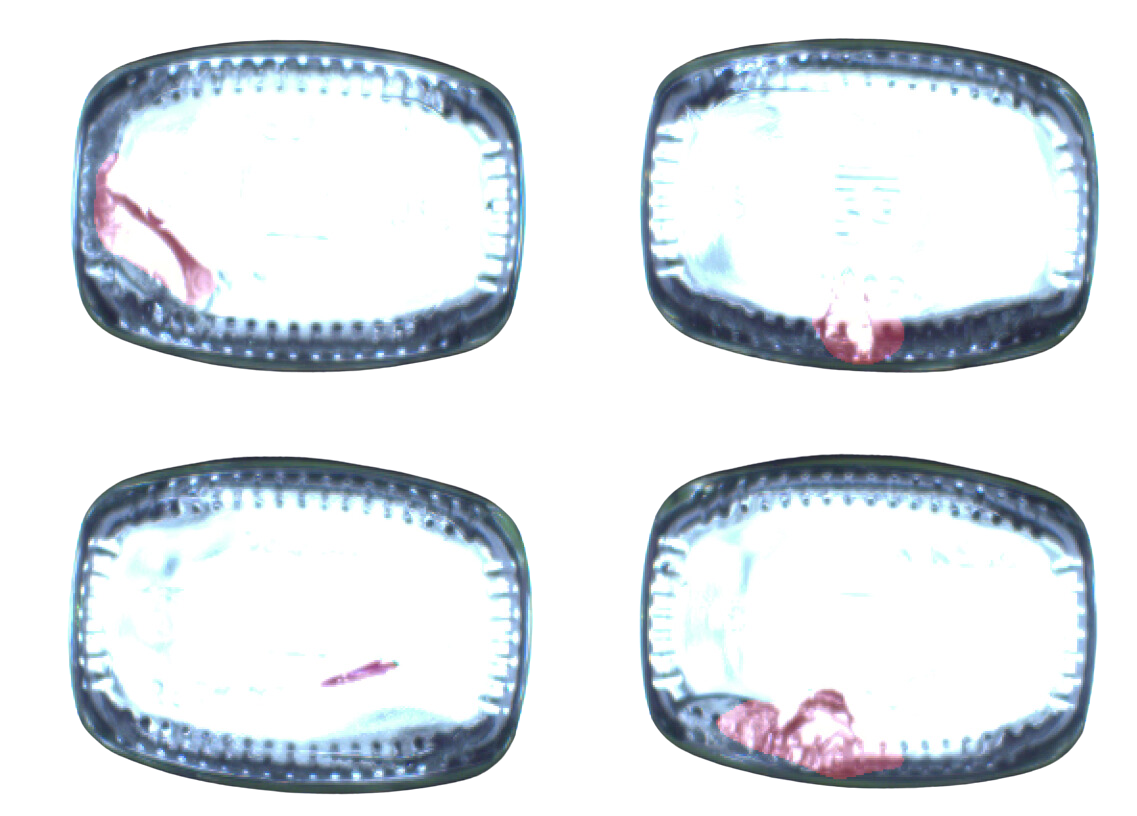

Comprehensive Glass Bottle Quality Inspection

Bottle quality inspection is a crucial process both inline and end-of-line in the bottling industry The inspection becomes particularly critical in the Food & Beverage, Consumer Packaging, Pharmaceutical, and Cosmetics sectors, where Packaging integrity impacts statutory compliance as well as product safety. However, this task comes with its own set of challenges.

Variability in Bottle Designs

Bottles come in various shapes, sizes, and colors, complicating the inspection process. This entails exhaustive training and is deeply dependent on the skills and patience of the Inspection workforce.

Material Transparency and Reflection

The transparent nature of glass and some plastics, combined with product labeling and varying liquid colors, can interfere with conventional inspection systems, leading to 8%+ false positives or missed defects.

High-Speed Production Lines

The production lines operate at high speeds of 300+ Parts per minute, making it challenging to manually inspect every crown exhaustively, and the misses lead to massive compliance and brand implications.

Integration with Existing Production Lines:

The defects in glass bottles are not easy to reproduce and the lines usually have limited space. Implementing bulky conventional systems with 30,000+ defect image requirements is very challenging.

Experience the Power of AI in Glass Bottle Inspection

System Setup

The customer installed the SwitchOn DeepInspect system at the empty-bottle section of the bottling line. The system had the following components:

The customer installed the SwitchOn DeepInspect system at the empty-bottle section of the bottling line. The system had the following components:

2 Cameras for Side wall inspection

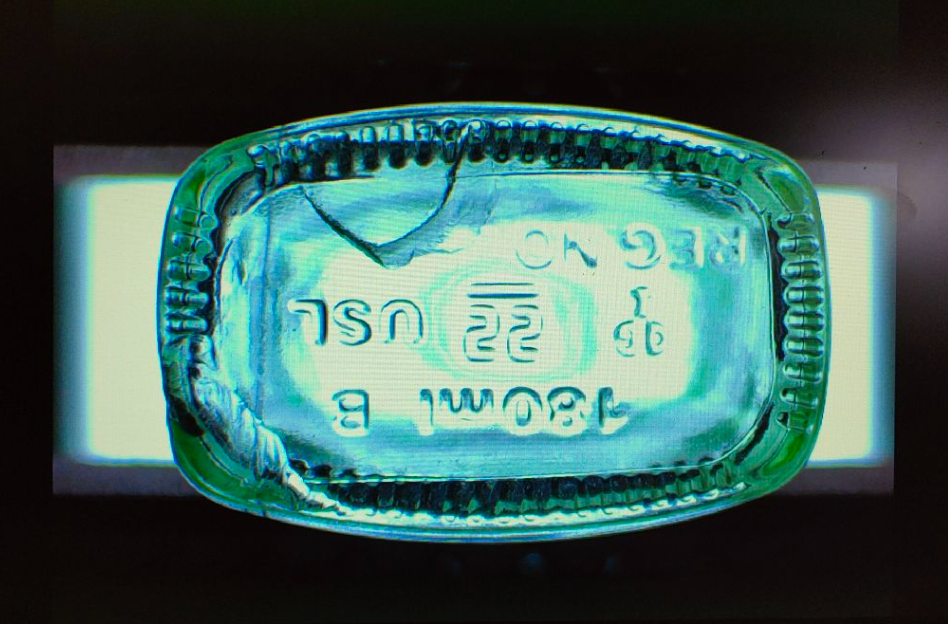

1 Camera for inspecting the bottom for settled particles

1 Camera for the bottle top/crown

The entire system was completely integrated into the line so that the inspection and the rejection could happen in real time. The customer achieved a zero-defect line at the end of the inspection stations.

Why is DeepInspect Better than Conventional Systems:

DeepInspect revolutionizes crown inspection with its state-of-the-art, AI-enabled surface inspection tool, designed to overcome the major drawbacks in traditional machine vision pixel-based tools

High-Speed Inspection: The customer inspected products running at a remarkable 320 parts-per-minute with DeepInspect. The customer was hence, able to do real-time inspection even in high-throughput production environments.

Handling Variability in Crowns: Deepinspect is adept at handling variability. They can be trained on a wide range of crown variations enabling them to accurately identify defects with low false positives due to good part variati

Reducing False Positives and Negatives: The customer reached <0.5% false-positive rates leading to minimal wastage and increased adoption. Furthermore, the customer was able to finely balance sensitivity and specificity, reducing the occurrence of false positives and negatives.

Product Highlights

Quick SKU Training: Teach new SKUs with fewer than 200 images.

Easy Setup: Implement automated quality inspection in under an hour.

Comprehensive Coverage: Expand inspection scope with 3+ cameras integrated into a single system for more coverage.

DeepInspect has been successfully integrated by our clients, streamlining the inspection process in bottle-filling operations. Experience the future of AI-driven quality control with DeepInspect, where precision meets efficiency.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Learn More?

Download the full use case below!