Closure Cap Inspection using AI and Machine Vision

Closure Cap Inspection using AI and Machine Vision

Related Articles

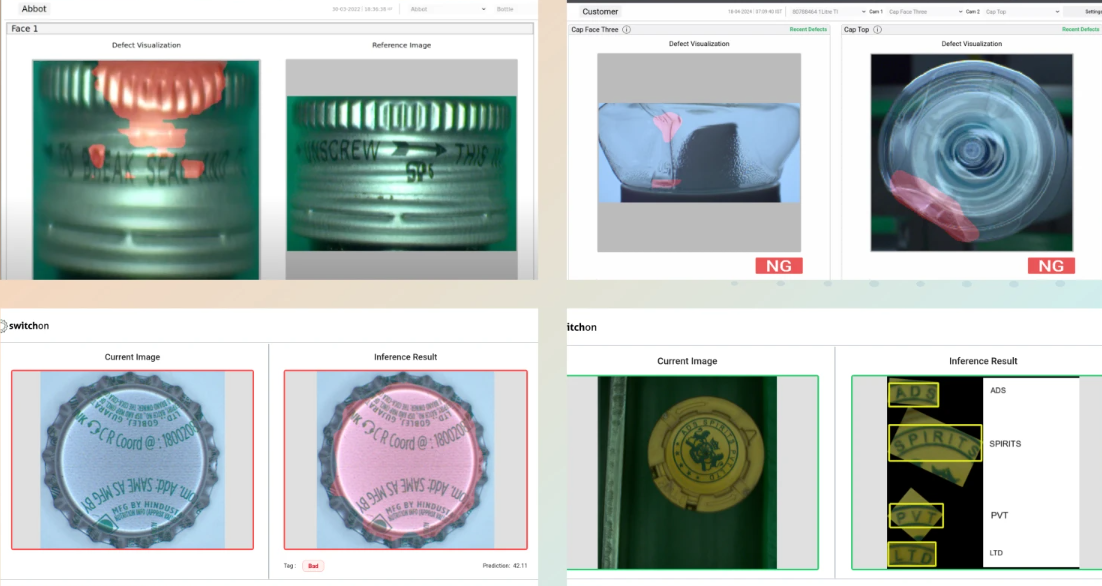

AI powered Closure inspection at 1000 PPM

Visual quality inspection for closures, such as bottle caps, presents several significant challenges. These include their complex shapes, continuous rotation during production, and high operational speeds, typically exceeding 1000 parts per minute (PPM). These factors make it difficult to identify defects with traditional inspection methods, which can lead to quality control issues and increased wastage.

Optimal Placement of Closure Inspection Systems

To ensure the highest quality of closures, it is crucial to strategically place inspection systems in the production process. There are two key locations for optimal placement:

At the Manufacturing Source:

Installing inspection systems at the manufacturing stage ensures that closures are defect-free before they leave the production line. This proactive approach prevents defective caps from impacting filling machines and reduces wastage. By catching defects early, manufacturers can avoid the costly repercussions of defective closures in subsequent stages of production and packaging.

Post-Filling Station:

Inspection systems at the post-filling stage monitor automated or manual capping operations. Any issues with the capping machines can lead to damaged closures, improper sealing, spillage, and product returns. By inspecting closures after they are placed on bottles, manufacturers can ensure that any defects introduced during capping are detected and addressed before products reach consumers.

DeepInspect’s AI-powered surface inspection tools provide complete defect coverage with high speed, accuracy, and minimum false-positives(wastage).

What can you do only with DeepInspect

Quick SKU Training

DeepInspect enables rapid training of new Stock Keeping Units (SKUs) with fewer than 200 images, making it easy to adapt to different closure designs. This capability is particularly valuable as it eliminates the need for extensive datasets covering all possible defect variants, streamlining the inspection process.

Comprehensive Coverage

Utilizing up to three cameras in a single system, DeepInspect ensures complete coverage of closures from multiple angles. This multi-camera approach enhances the detection of defects that might be missed with a single viewpoint.

Detecting Various Cap Issues

DeepInspect can identify a wide range of defects, including misplaced closures, incorrect logos, missing date codes, artwork issues, printing defects, appearance flaws, and scratches on both plastic and metal closures. This versatility ensures that all potential quality issues are detected and addressed.

Defect Analytics and Root-Causing

Analyze all inspected closures to drive continuous improvement. Provides actionable insights into defect patterns and root causes, empowering teams to improve quality and prevent recurrence.

System Hardware Specifications

DeepInspect Pro Software

High-speed 1.6MP+ Basler Industrial camera

Mitsubishi High speed PLC

Controller with i5 and Nvidia GPU

High-speed pneumatic-based rejection system with 5 ms response time

Integration with Manufacturing Lines

DeepInspect can be seamlessly integrated or retrofitted into existing production lines or Special Purpose Machines (SPM). The integration process is typically non-intrusive and does not interfere with the product flow. If necessary, DeepInspect’s system integrators can also develop new SPMs with built-in inspection capabilities, ensuring a tailored solution for any manufacturing setup.

Used by Global FMCG and Beverage Companies

Global F&B and CPG Majors have successfully integrated DeepInspect to enhance their closure manufacturing and post-filling capping operations. Optimize your closure quality control with DeepInspect’s advanced visual inspection systems and ensure top-notch product standards throughout your manufacturing and packaging processes.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.