Mould code reader software for glass container manufacturing

DeepInspect®- Glass Bottle Moulding Number Reader System | AI Vision OC Software

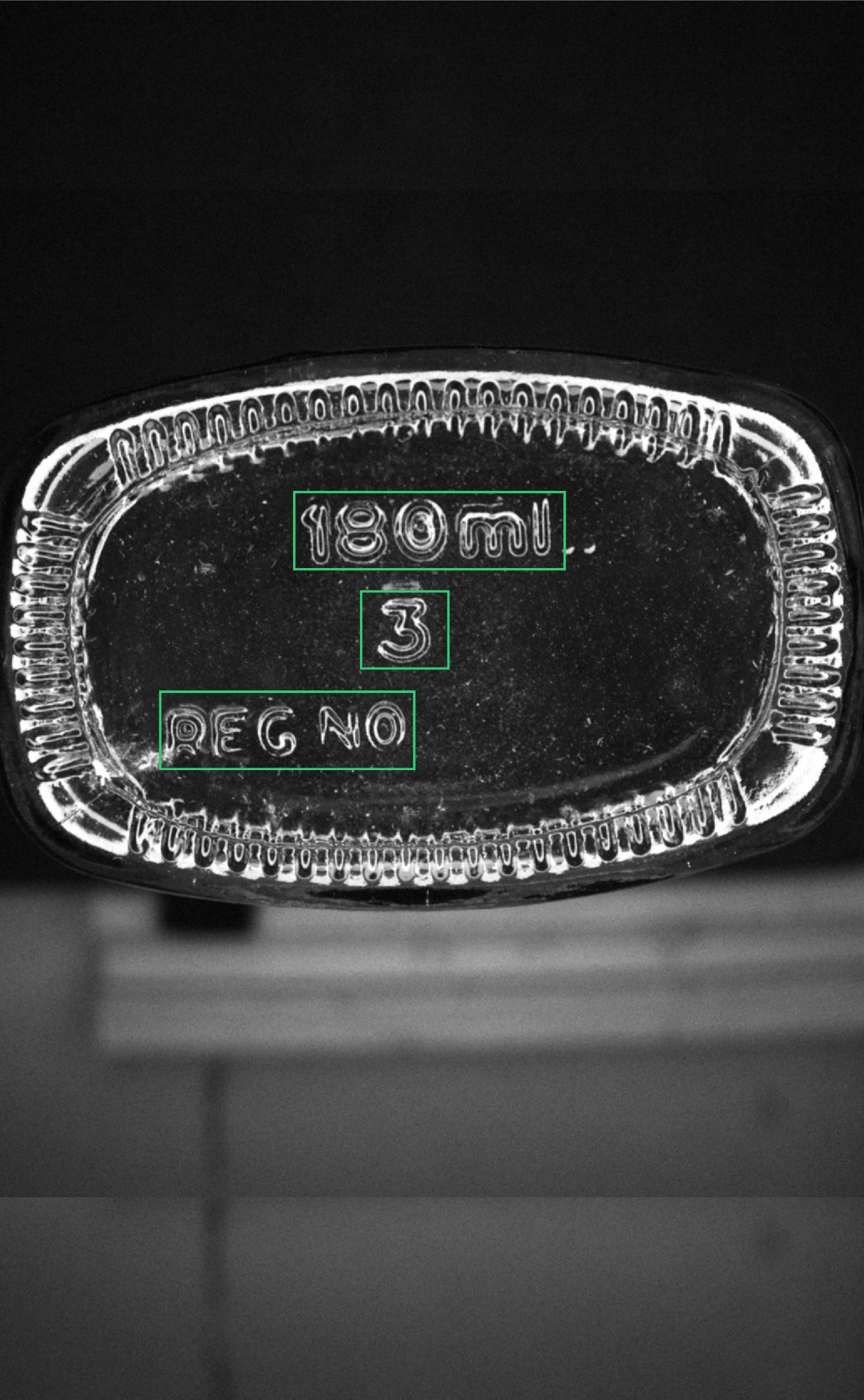

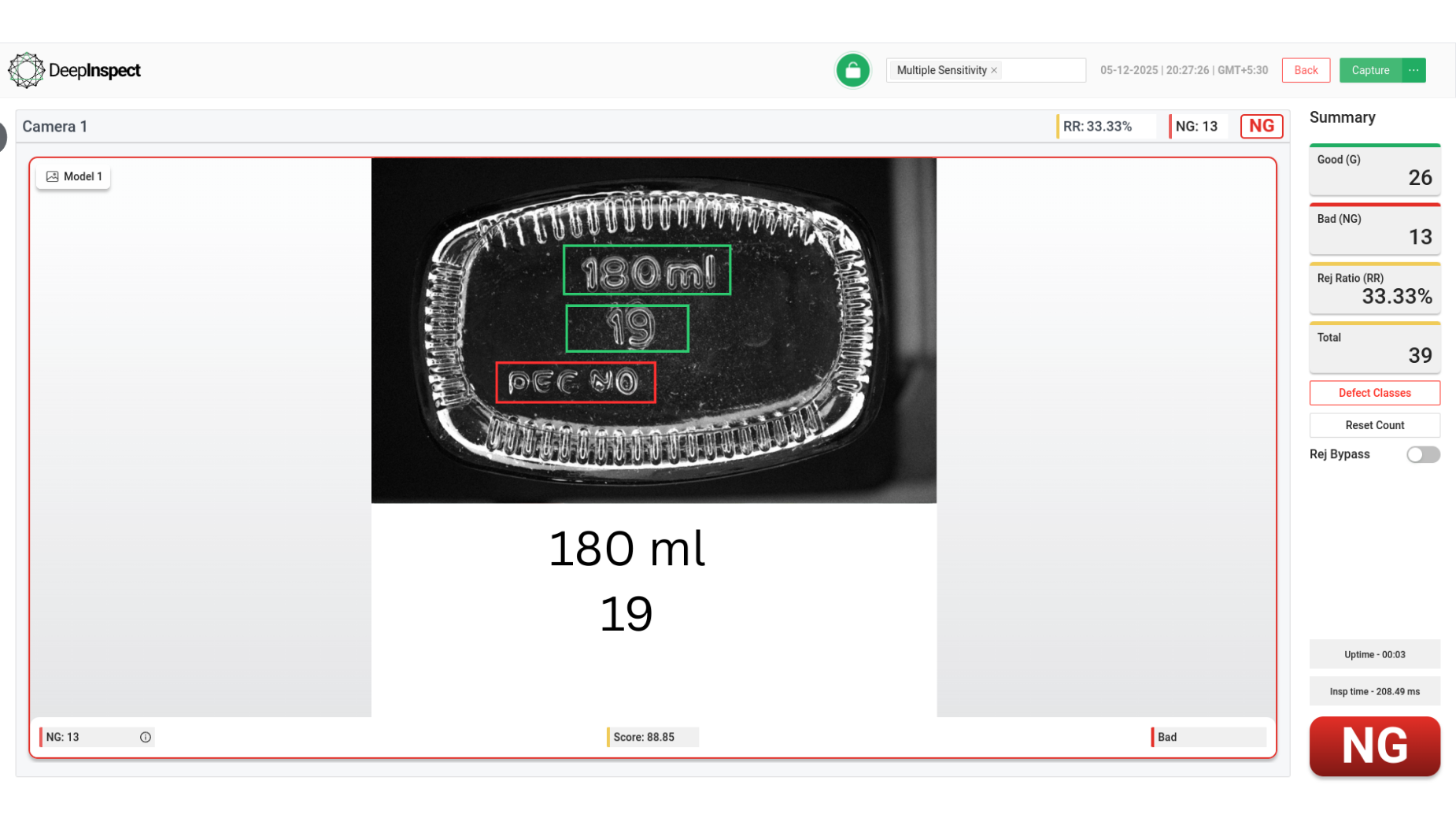

Mould Number Reading(MNR) using DeepInspect® enables accurate and automated identification of mould numbers on glass bottles, even on transparent and curved surfaces. Traditional OCR and manual inspection struggle with low contrast, reflections, wear, and partial imprints. DeepInspect® overcomes these challenges using AI-driven vision models that learn real-world variations in mould numbers, including deformation, fading, and contamination. The system requires fewer than 200 good images for training and can be deployed rapidly, with model training completed in under 45 minutes. Delivering up to 99.5% detection accuracy with false positives below 0.5%, DeepInspect® ensures reliable mould traceability, faster root-cause analysis, and consistent quality control without impacting production throughput.

USECASE

Defects Detected by DeepInspect®

DeepInspect® detects all defects, such as

DeepInspect® detects missing moulding numbers, ensuring reliable traceability and consistent QC

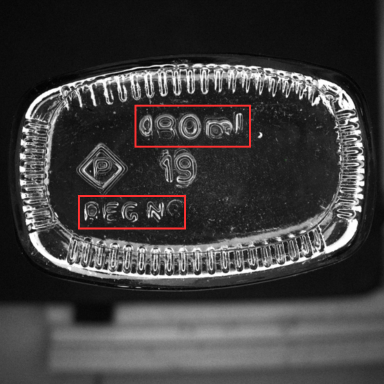

Incomplete mould numbers are reliably detected, ensuring accurate defect identification

Low contrast moulding defects are detected using DeepInspect®, despite surface variability

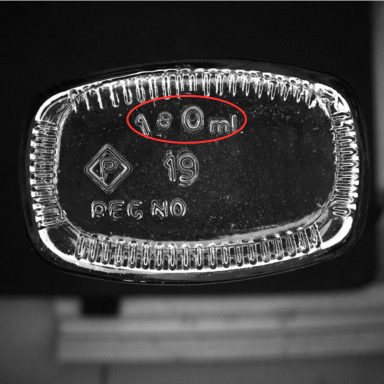

Distorted character defects are detected using DeepInspect®, ensuring reliable defect isolation

Automated mould number reading system for beverage bottles

Missing Moulding Number

Incomplete Moulding Number

Low-Contrast Moulding

Distorted MNR Characters

Bottle Mould Number Reader(MNR) for Glass Bottles

Best glass bottle mould number reading software

Industrial machine vision mould number reading software with 99.5% Accuracy

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

1000+PPM: High-speed inspection, detecting 1000+ parts per minute

Mould number reader for beer & beverage bottle manufacturers

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in glass container traceability solutions using AI?

Book a free demo!

Inquiry Form

MNR is an automated vision-based process used to detect and read mould numbers embossed on glass bottles for traceability and quality control.

MNR helps identify defective mould cavities, enables faster root-cause analysis, and supports compliance, recalls, and quality audits.

AI vision systems use advanced imaging and trained models to read embossed mould numbers despite low contrast, curvature, and reflections.

Common MNR defects include missing, incomplete, distorted, low-contrast, worn, or incorrect mould numbers.

Challenges include reflections, low contrast, curved surfaces, contamination, and mould wear affecting character clarity.

Yes, modern AI-based MNR systems are designed to operate in real time without impacting production throughput.

AI-driven MNR systems like DeepInspect can achieve up to 99.5% detection accuracy with minimal false positives