Exploring DeepInspect Read OCR/OCV in FMCG

Discover DeepInspect Read OCR/OCV in FMCG

Related Articles

Challenge

Our customer, India’s largest FMCG brand, needed a solution to automate Optical character recognition and verification on all manufactured SKUs and automate for continuous production

The primary challenges included:

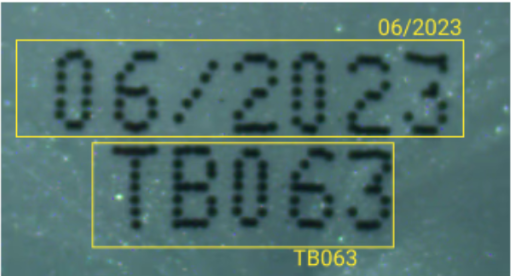

Comprehensive Character Coverage: Ensuring 100% coverage for all characters, including special characters (#,@,₹,/), at 580+ parts per minute.

High Detection and Rejection Accuracy: Achieving 99.9%+ accuracy in character detection while minimizing false rejections(<0.5%). The system needed to adapt to minor changes in print quality.

Printer Integration: The printed text continuously changes on the shift, so there was a need to deeply integrate with the Printer to automatically verify the text as it gets printed.

Solution

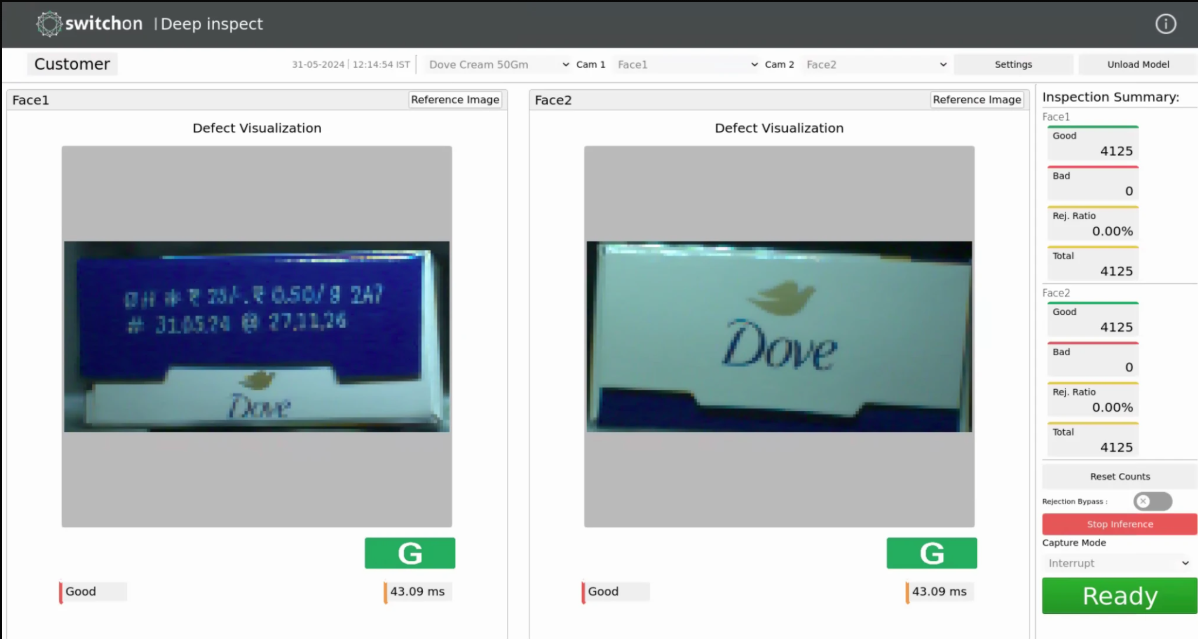

The customer implemented the DeepInspect Read system, and the following are the major features that stood out for them:

Comprehensive OCR at High-Speed: DeepInspect Read supported all characters at a remarkable variable speed of 580+ parts per minute. The proprietary edge AI OCR technology delivered both exceptional detection capabilities and speed.

Robust Verification: DeepInspect Read used AI to exhibit robustness against minor variations in print quality, providing <0.5% false-positive rate and superior accuracy than all existing conventional solutions.

Seamless Integration to the existing printer: DeepInspect Read seamlessly integrated with the existing VideoJet Printer, automating the verification process and eliminating the need for manual intervention.

Results

Following the implementation our customer experienced significant improvements in their operations:

Improved Compliance:

Streamlined and automated verification processes resulted in complete compliance with industry regulations.

Reduced the risk of errors and discrepancies, positioning the company as an industry leader in Quality.

Employee Productivity:

Automation of verification rules and continuous production processes led to zero manual intervention.

Conclusion:

Our customers’ immediate quality challenges have been revolutionized by the deployment of DeepInspect Read, leading to zero complaints over the months. Our customer has become an industry leader in leveraging AI for Operational Excellence.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.