Automated defect detection in PET preform manufacturing

DeepInspect® – High-speed machine vision system for PET preform inspection

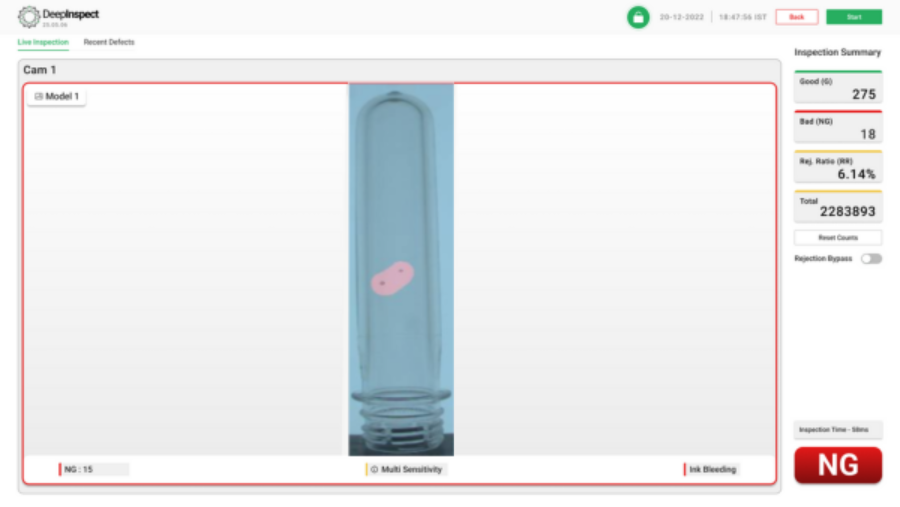

PET preform visual quality inspection using DeepInspect AI inspection software enables manufacturers to achieve consistent, high-speed, and zero-defect production. This automated PET preform inspection system uses advanced machine vision and deep learning to perform real-time PET preform defect detection, identifying black dots, bubbles, short shots, gate defects, flash, ovality, scratches, contamination, and neck finish defects. The PET preform camera inspection system integrates seamlessly with industrial cameras and optimized lighting to capture micro-level surface and dimensional variations at ultra-high speeds. With AI-powered PET preform inspection, model training requires fewer than 200 good images and is completed in under 45 minutes, ensuring rapid deployment. Inline PET preform quality control ensures 100% inspection coverage, automatic rejection of defective parts, and actionable analytics on cavity-wise performance and process drift. Unlike rule-based systems, DeepInspect delivers 99.5% inspection accuracy with less than 0.5% false positives, enabling beverage, FMCG, and pharma manufacturers to reduce wastage, prevent bottle failures, and improve overall production efficiency

USECASE

Defects Detected by DeepInspect®

DeepInspect® detects all surface and dimensional defects, such as:

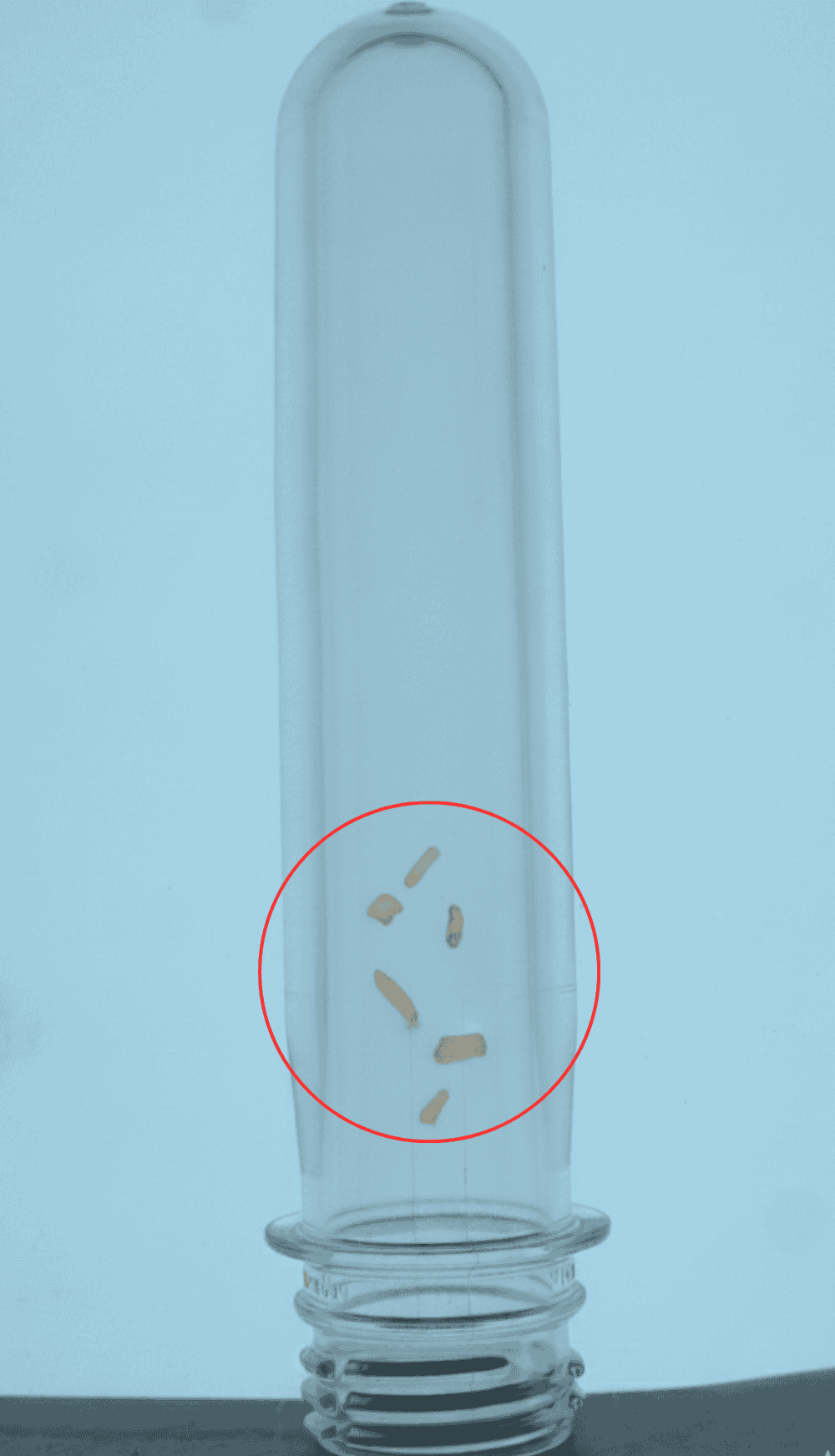

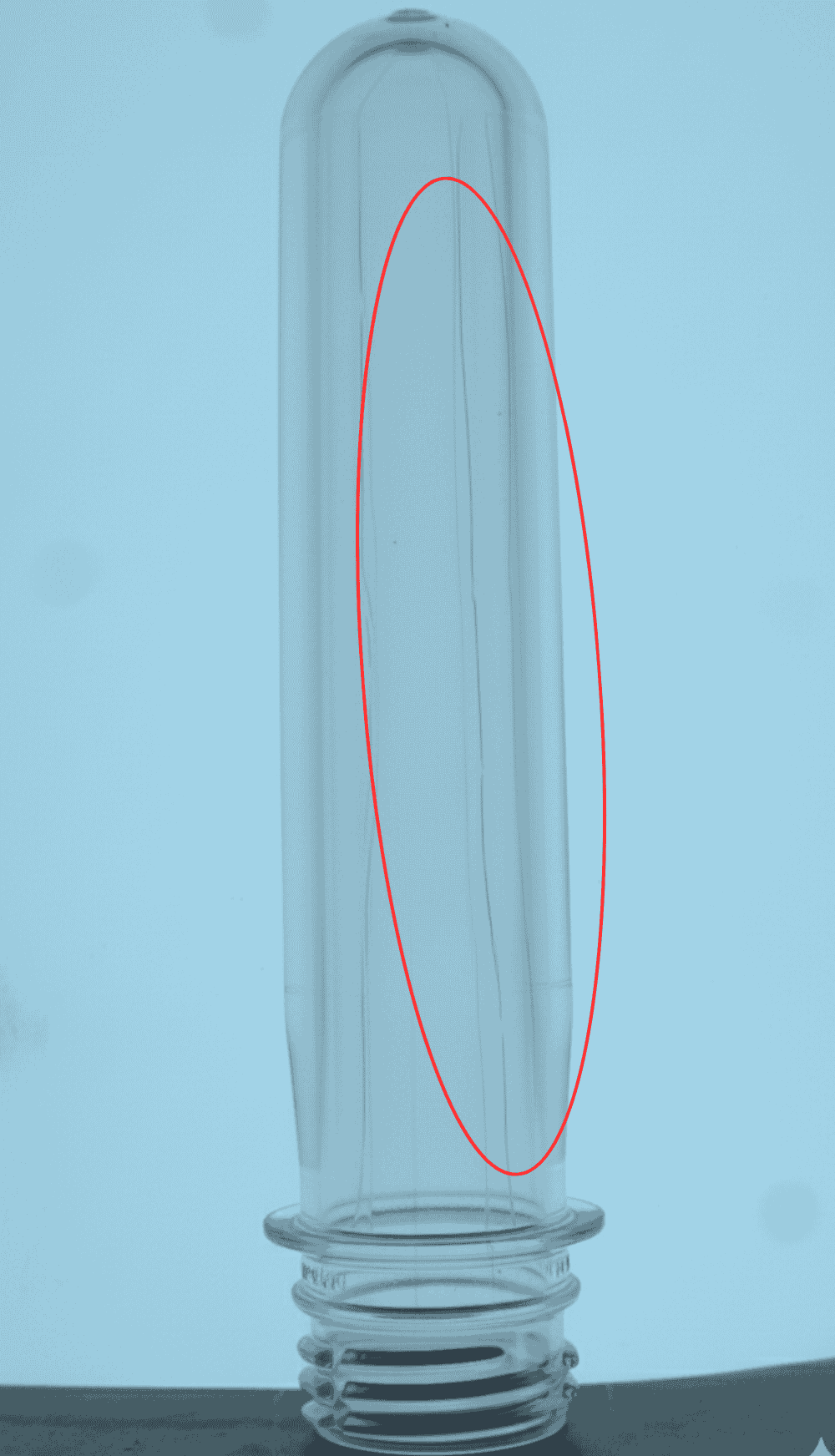

Precisely detects black dots, scratches, haze, and contamination on PET preforms in real time

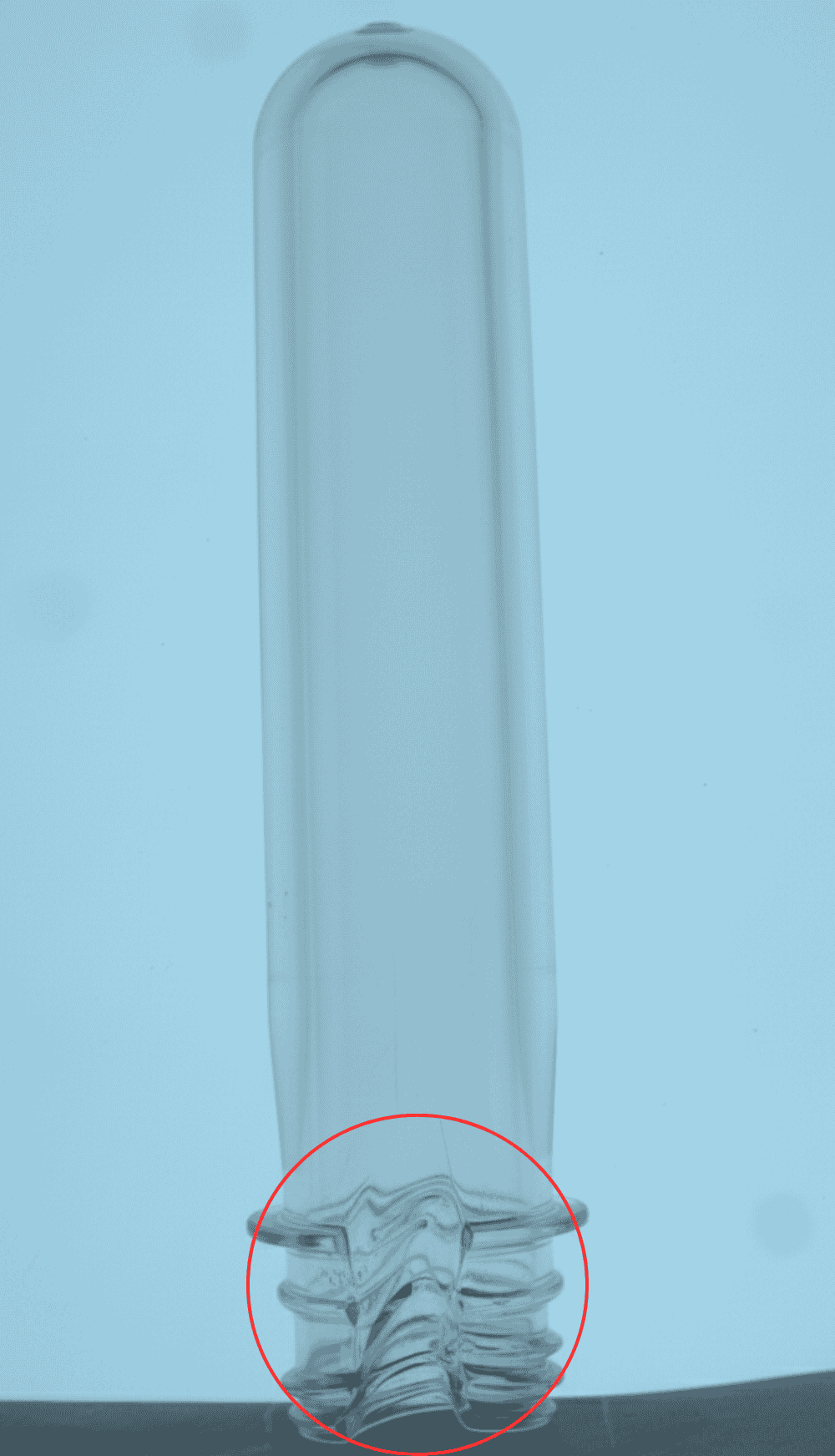

Identifies thread deformities, flashes, chips, and oval finishes, ensuring perfect capping and sealing

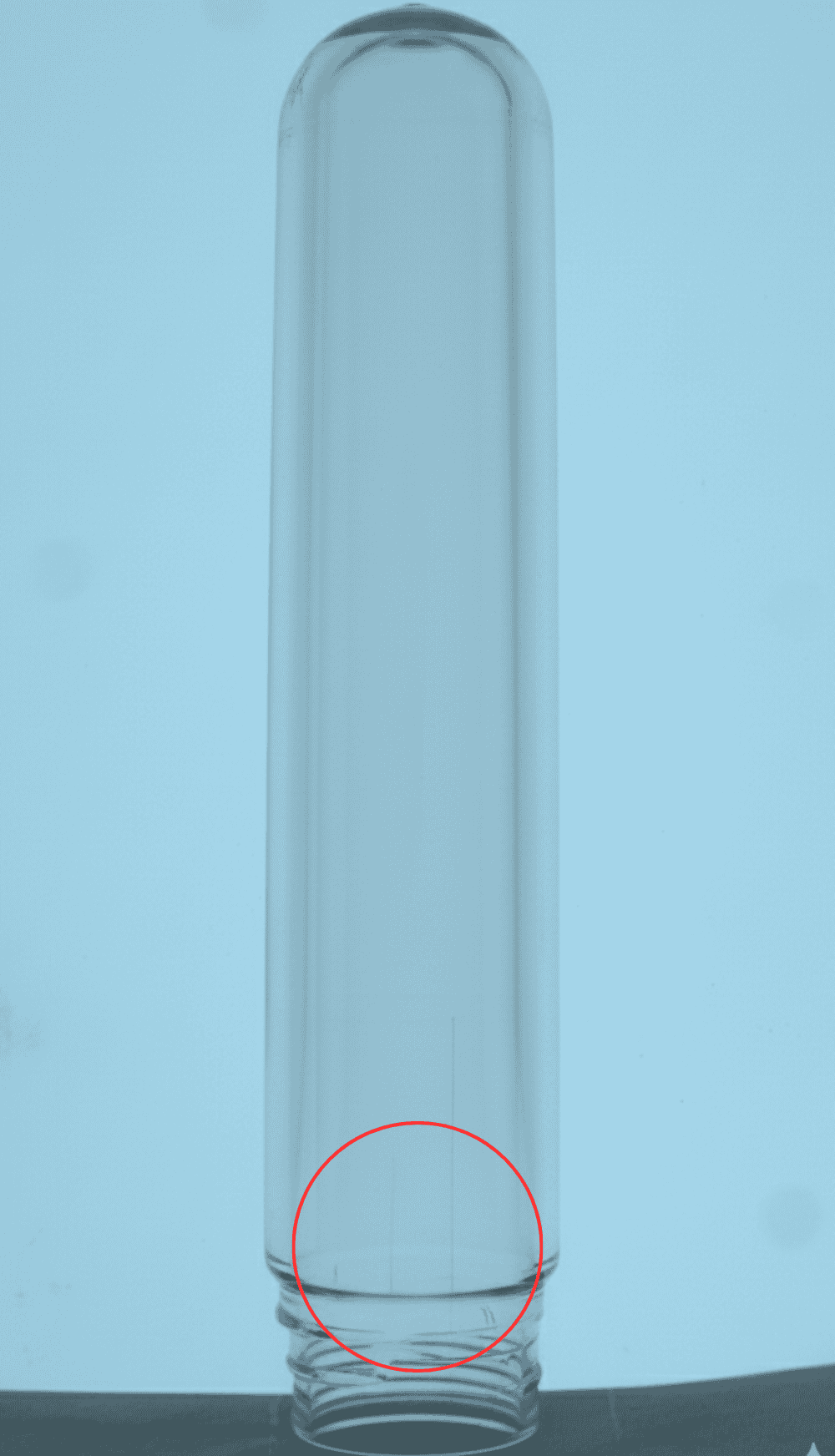

DeepInspect detects short shots, bubbles, sink marks, warpage, and gate defects with high accuracy

Verifies ovality, length variation, thickness inconsistency, and off-center gates

PET preform quality inspection for beverage bottles

Bubble formation

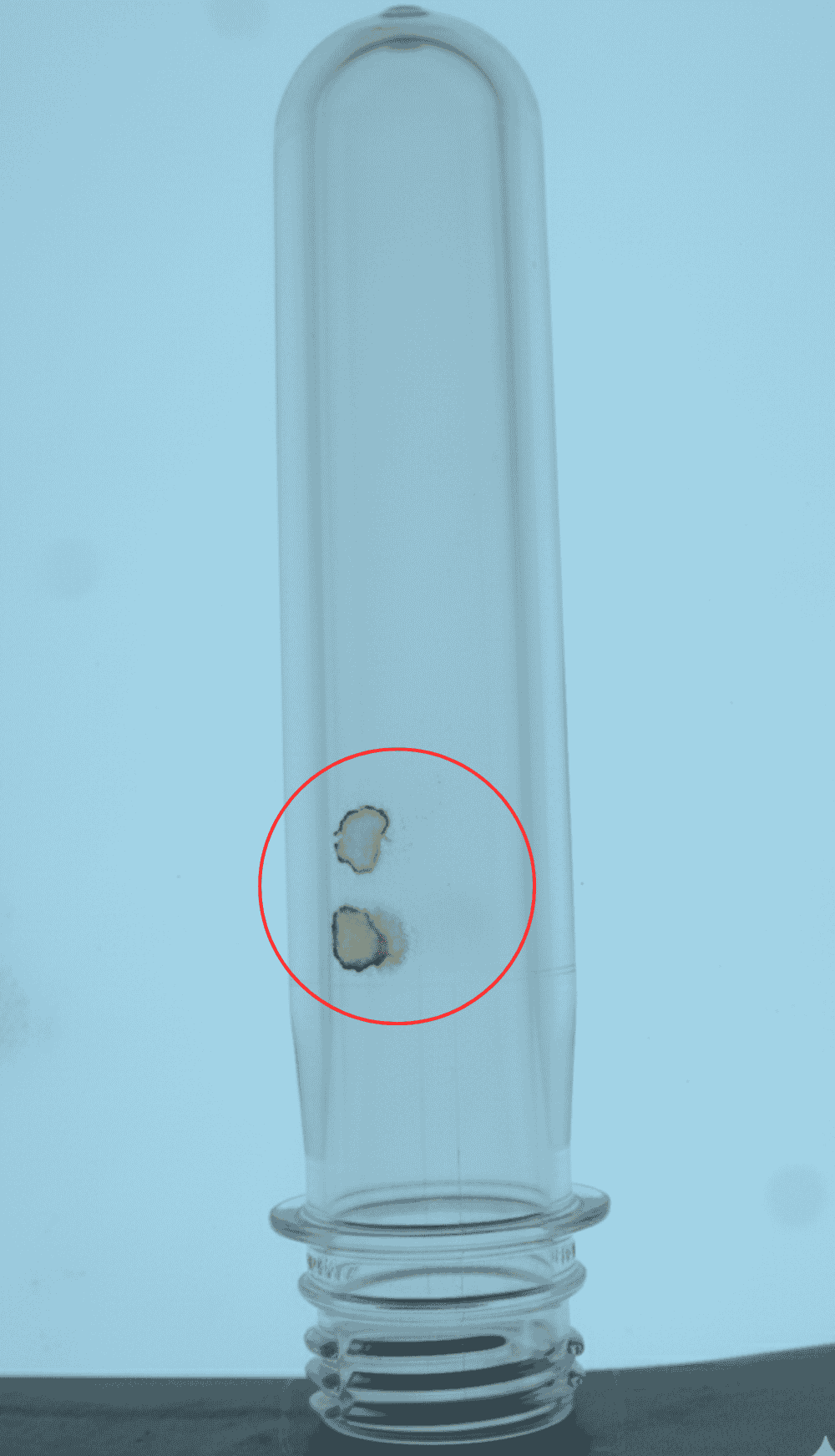

Burn marks

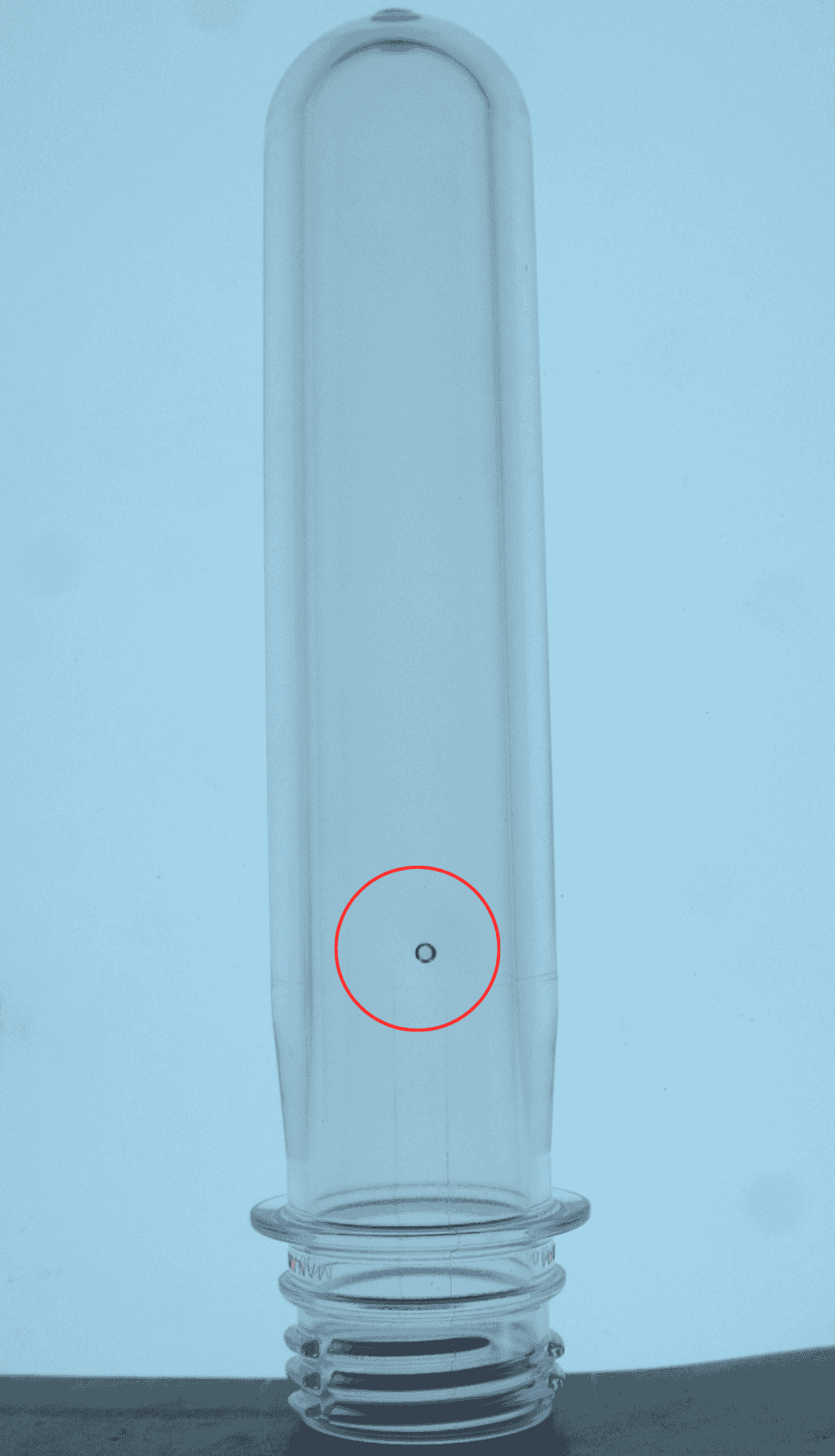

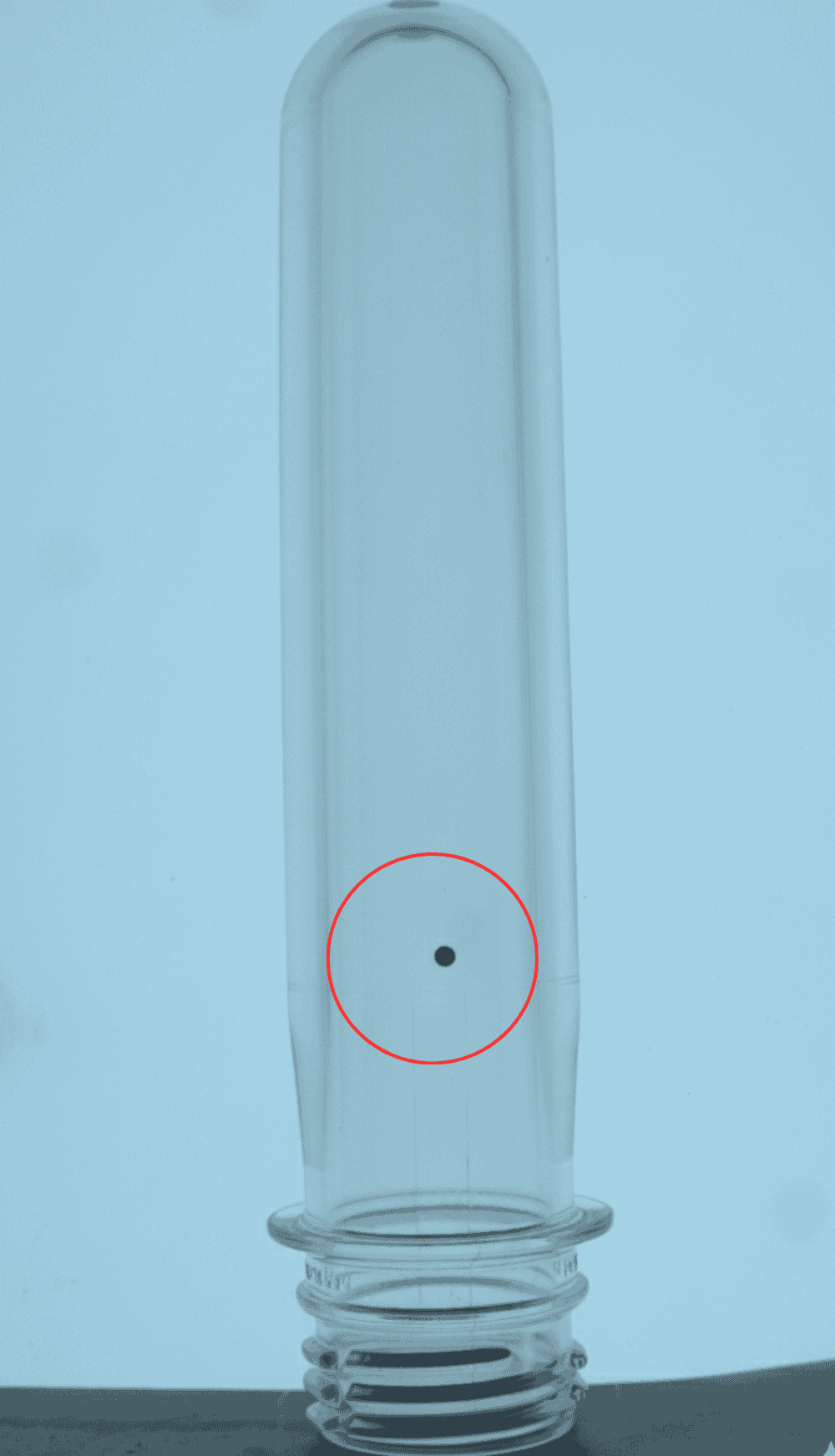

Black dots

Deformed threads

Short neck finish

Contamination

Flow lines

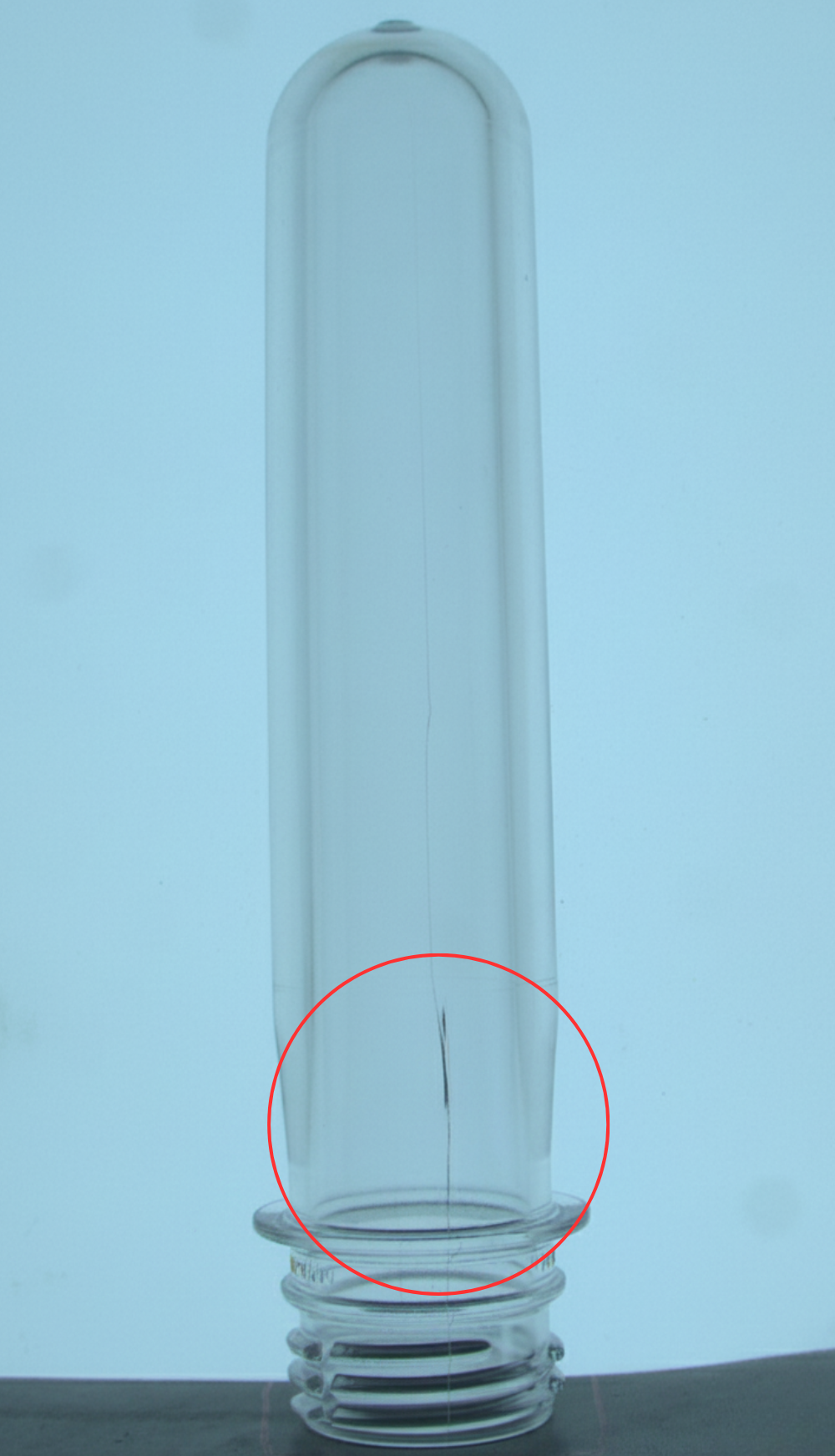

Cracks

DeepInspect®- Best AI-based visual quality inspection software for PET preforms

Ensure zero-defect PET preform manufacturing

Top vision inspection system for PET preforms

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

1000+PPM: High-speed inspection, detecting 1000+ parts per minute

PET preform contamination detection for high-speed lines

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in FMCG production line quality control automation?

Book a free demo!

Inquiry Form

PET preform inspection is the process of detecting defects in PET preforms using AI-powered vision inspection systems

Visual inspection ensures defect-free molding, prevents bottle failures, and maintains consistent packaging quality

Common defects include black dots, bubbles, short shots, flash, neck deformities, and contamination.

AI enables automated, real-time detection with over 99% accuracy, outperforming manual inspection.

Yes, AI vision systems easily detect subtle black dots and contamination inside transparent PET preforms

DeepInspect® requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect® uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

Yes, AI-based PET preform inspection systems support high-speed manufacturing without compromising accuracy.

Yes. DeepInspect® uniquely integrates surface defect detection and print verification into a single AI-powered platform, delivering complete cosmetic tube quality assurance.