Ensuring Precision Quality Control for Pouches

Precision Quality Control for Pouches with DeepInspect®

Related Articles

Introduction

Pouches are becoming a popular choice for individuals seeking a tobacco-free nicotine experience. However, ensuring the quality and safety of these pouches is crucial to maintaining customer trust and adhering to industry standards. Manufacturers often face challenges such as detecting defects that compromise product integrity.

In this blog, we will explore the challenges nicotine pouch manufacturers face, the types of defects that impact quality, and how DeepInspect® revolutionizes quality control processes.

What is a Pouch?

Pouches are small, smokeless products made of fibrous materials containing nicotine, flavorings, and fillers. Designed for discretion, they offer a tobacco-free alternative to traditional nicotine products. Users place them between their gums and lips for a consistent nicotine experience. Their growing popularity has increased the demand for high-quality, defect-free pouches.

Types of Defects in Pouches

Defects in nicotine pouches can affect both product performance and consumer safety. Common defects include:

Challenges Manufacturers Face Due to These Defects

Inconsistent Nicotine Delivery

Defects can cause over- or under-delivery of nicotine, leading to potential health issues like nausea, headaches, or withdrawal symptoms.

Health Hazards

Exposure to contaminants or allergens due to defective pouches can harm consumer well-being and expose manufacturers to legal liabilities.

Loss of Consumer Trust

Defective products erode brand loyalty, creating negative perceptions about the company's commitment to quality.

Operational Inefficiencies

Manual inspection processes are time-consuming, error-prone, and expensive, often failing to achieve the desired precision.

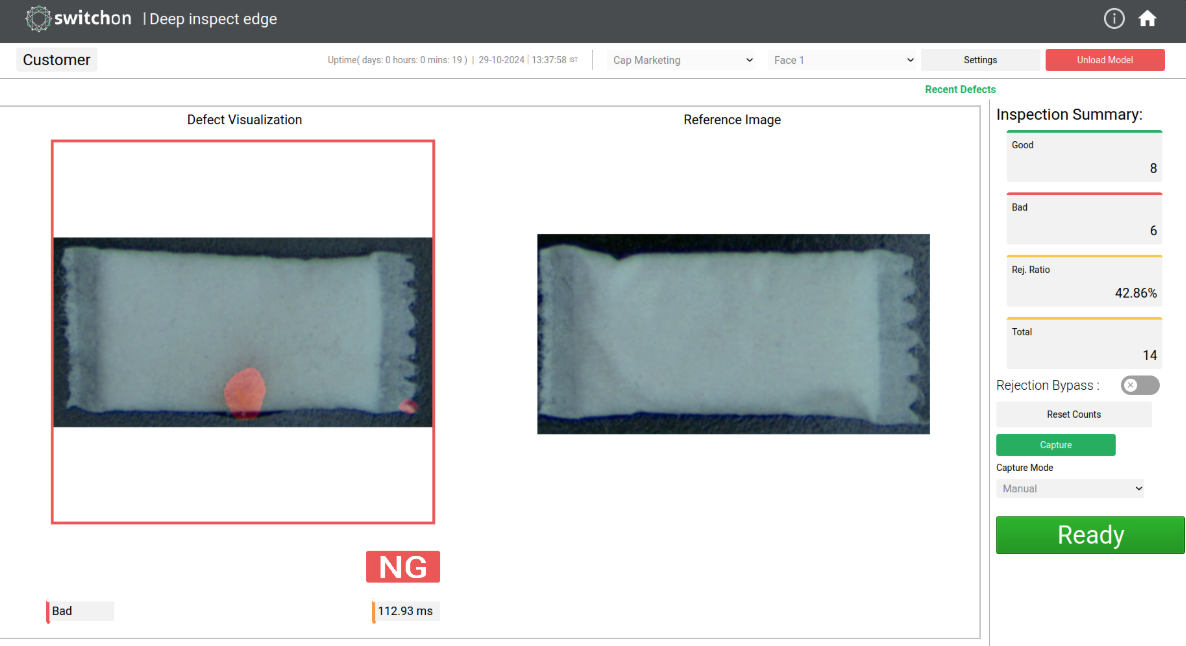

DeepInspect®: Nicotine Pouch Visual Quality Inspection Software

Key Components of the DeepInspect Setup

DeepInspect Software: The AI-powered system at the heart of inspection.

Industrial Controller: Equipped with an i5 processor and GPU for fast data processing.

Industrial Vision Lights & Camera: Ensure high-quality images for precise defect detection.

DeepInspect® is an AI- Powered visual quality inspection software tailored to meet the quality control needs of nicotine pouch manufacturers. DeepInspect AI model requires only less than 200 good nicotine pouch images for model training, enabling it to identify surface defects such as cut seals, unsealed edges, slicing errors, foreign particles, and unsliced pouches with 99.5% accuracy and a false positive rate below 0.1%. The system incorporates strategically positioned lighting to enhance visibility, allowing the dual-camera setup—one above and one below the transparent conveyor—to capture clear, detailed images of the pouches from both sides. Defective pouches are efficiently removed in real-time using an air nozzle system, ensuring impeccable quality control.

Advantages of DeepInspect®

1. Unmatched Accuracy

Detects even the smallest defects, ensuring consistent product quality and consumer satisfaction.

2. Cost-Effective

Minimizes operational expenses and reduces wastage by automating defect detection.

3. Compliance and Safety

Helps manufacturers meet industry standards and avoid costly recalls or penalties by delivering defect-free products.

4. Enhanced Brand Reputation

Ensures consumer confidence and loyalty through the delivery of flawless nicotine pouches.

5. Efficiency and Scalability

Processes up to 300 pouches per minute, making it suitable for high-volume manufacturing environments.

Conclusion:

The DeepInspect® system is a game-changer for nicotine pouch manufacturers striving to ensure product quality and safety. By leveraging advanced imaging and AI-powered defect detection, it offers a reliable solution to longstanding challenges in the industry. With its precision, efficiency, and cost-effectiveness, DeepInspect® not only boosts operational performance but also reinforces consumer trust in the brand.

For manufacturers aiming to stay ahead in the competitive nicotine pouch market, DeepInspect® is the ultimate tool to achieve sustainable growth and long-term success.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Learn More?

Download the full usecase below!