Quality Inspection Reimagined

We have completely rethought visual inspection – From cutting-edge advancements in Deep Learning integrated into Computer Vision to the easy-to-use interface for our manufacturing customers

PRODUCT

Building AI Systems

Training time

False Positives

Production Accuracy

Inspection Speed

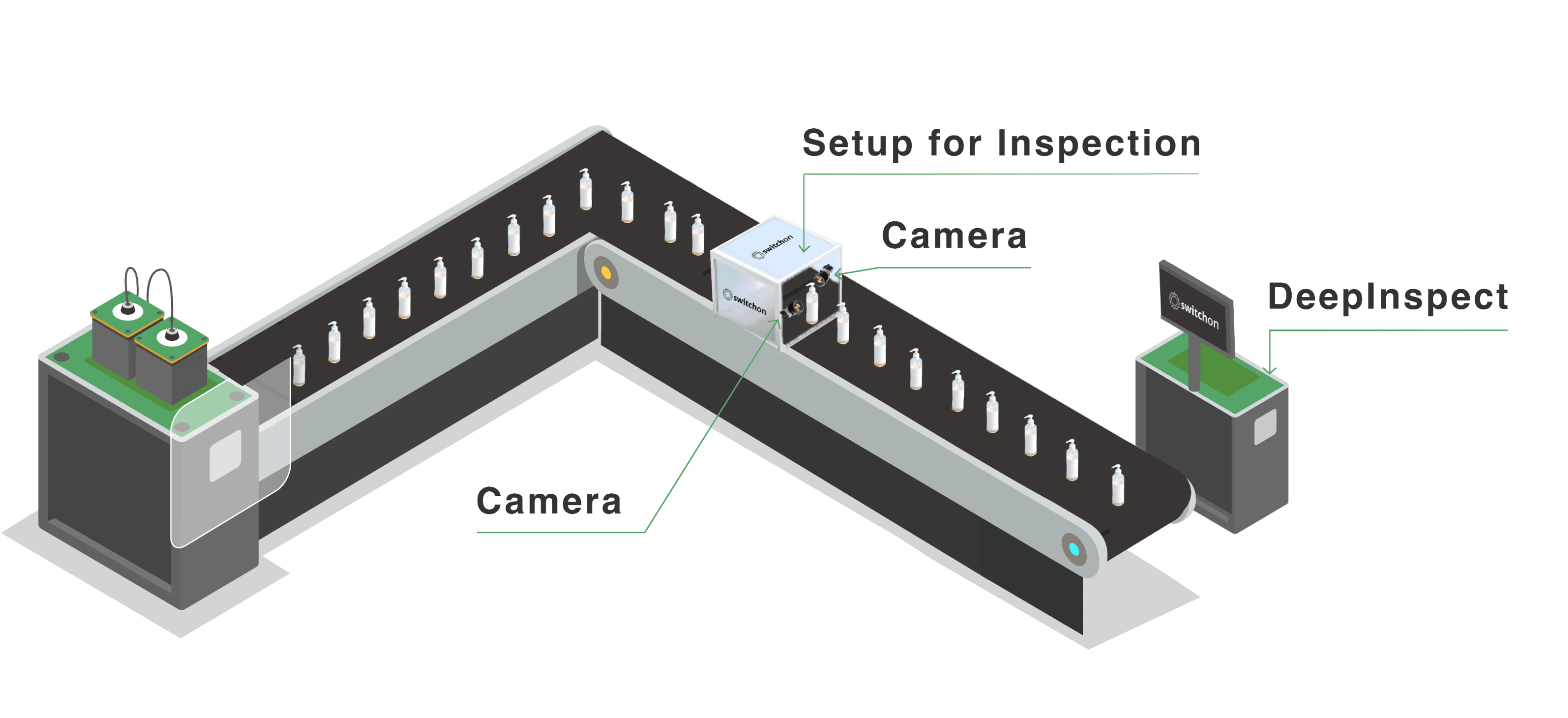

Deploy DeepInspect® in 3 Steps / 2 Weeks

Setup inspection in less than 1 hour

-

Leverage our no-code application to setup inspection for new SKUs. Get results without writing complex codes

-

Use latest tools in optical character verification and surface inspection

-

Train AI models without the need for a internal data science team

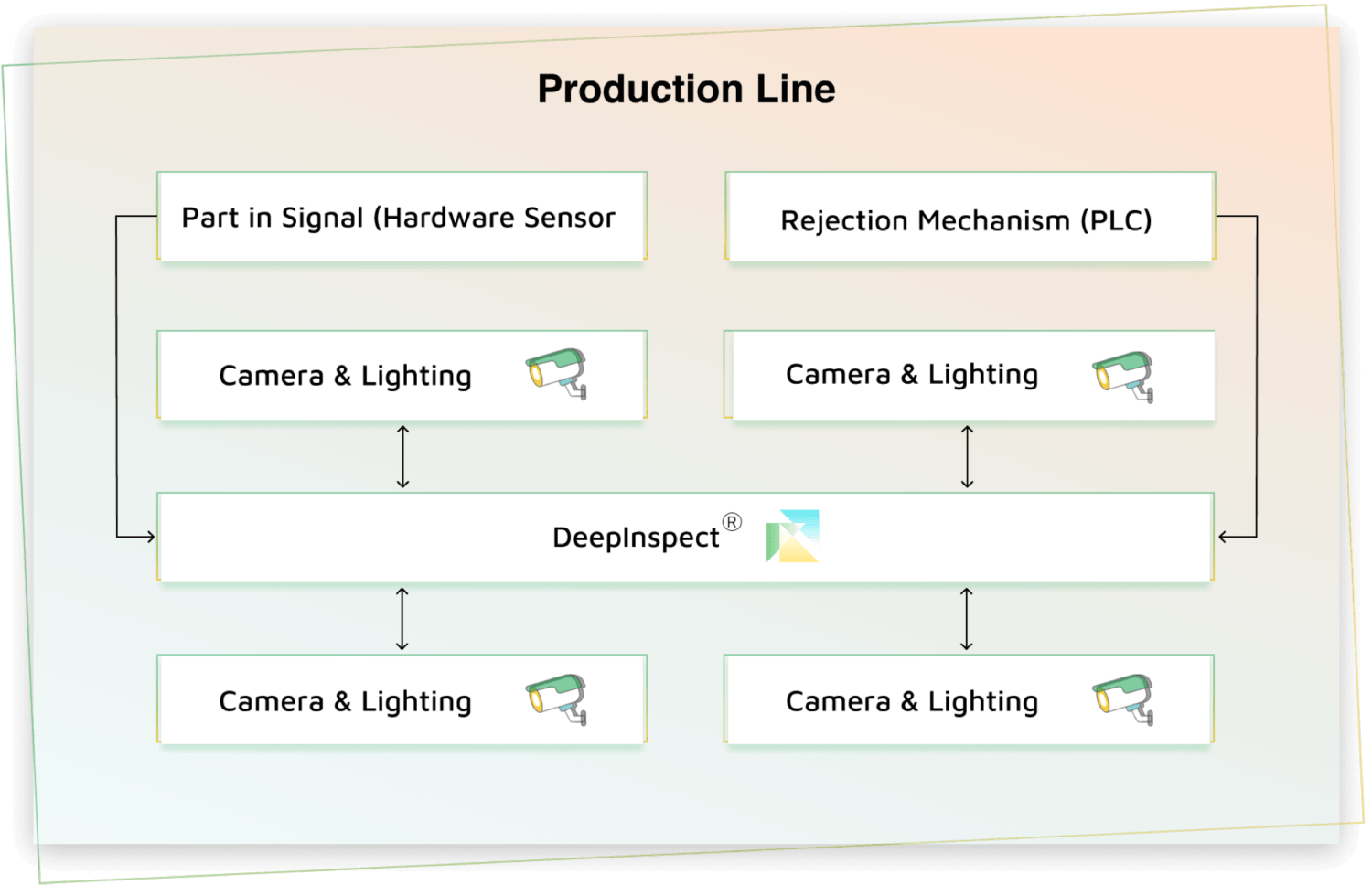

DeepInspect® Deployment & System Architecture

High-speed AI inspection at

1000+ parts per minute

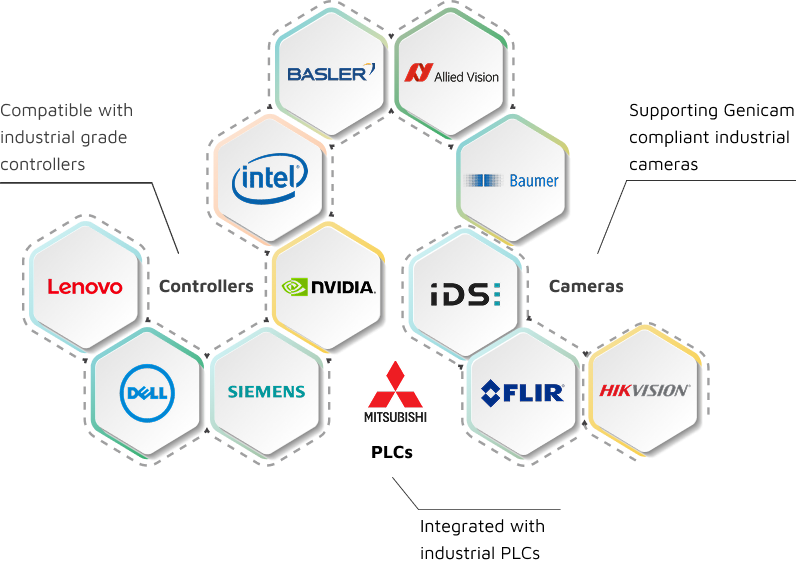

DeepInspect supports up to 8 industrial cameras in a single application, 1.3 to 20 megapixels, global and rolling shutter cameras

Runs high speed AI based inspection up to 1000+ PPM*; dependon multiple factors such as SKU, light, material handling, etc.

TCPI/IP and modbus enabled communication. Successfully integrated with Siemens, Delta, Omron, and Mitsubishi IOs

Seamlessly deploy 50+ models in a single system and continously improve performance with DeepInspect Train

Ability to automatically switch SKUs based on external triggers for seamless inventory and process management

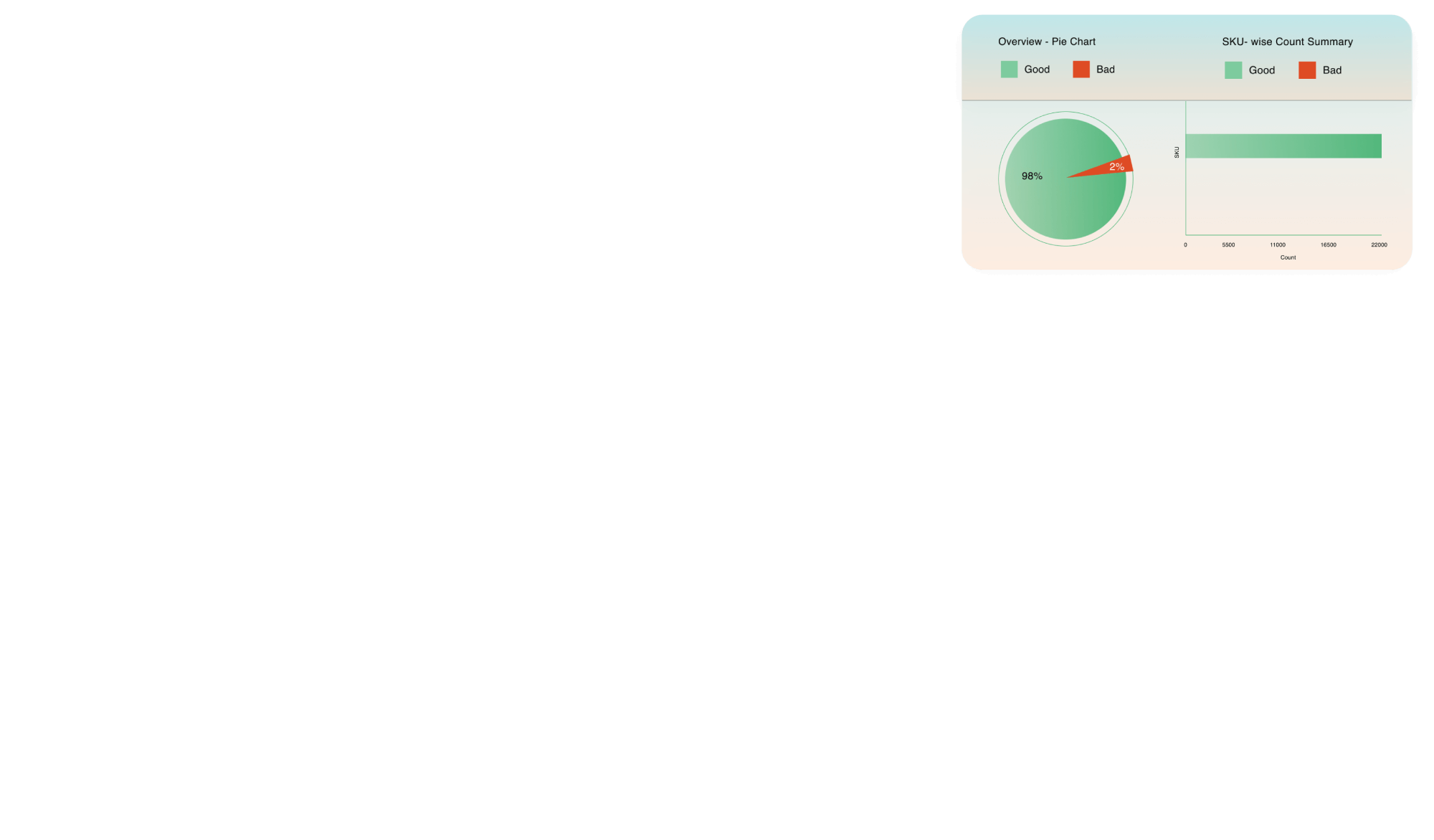

Enable traceability applications with 10k image save and inbuilt analytics to process and analyze collected data, providing actionable insights

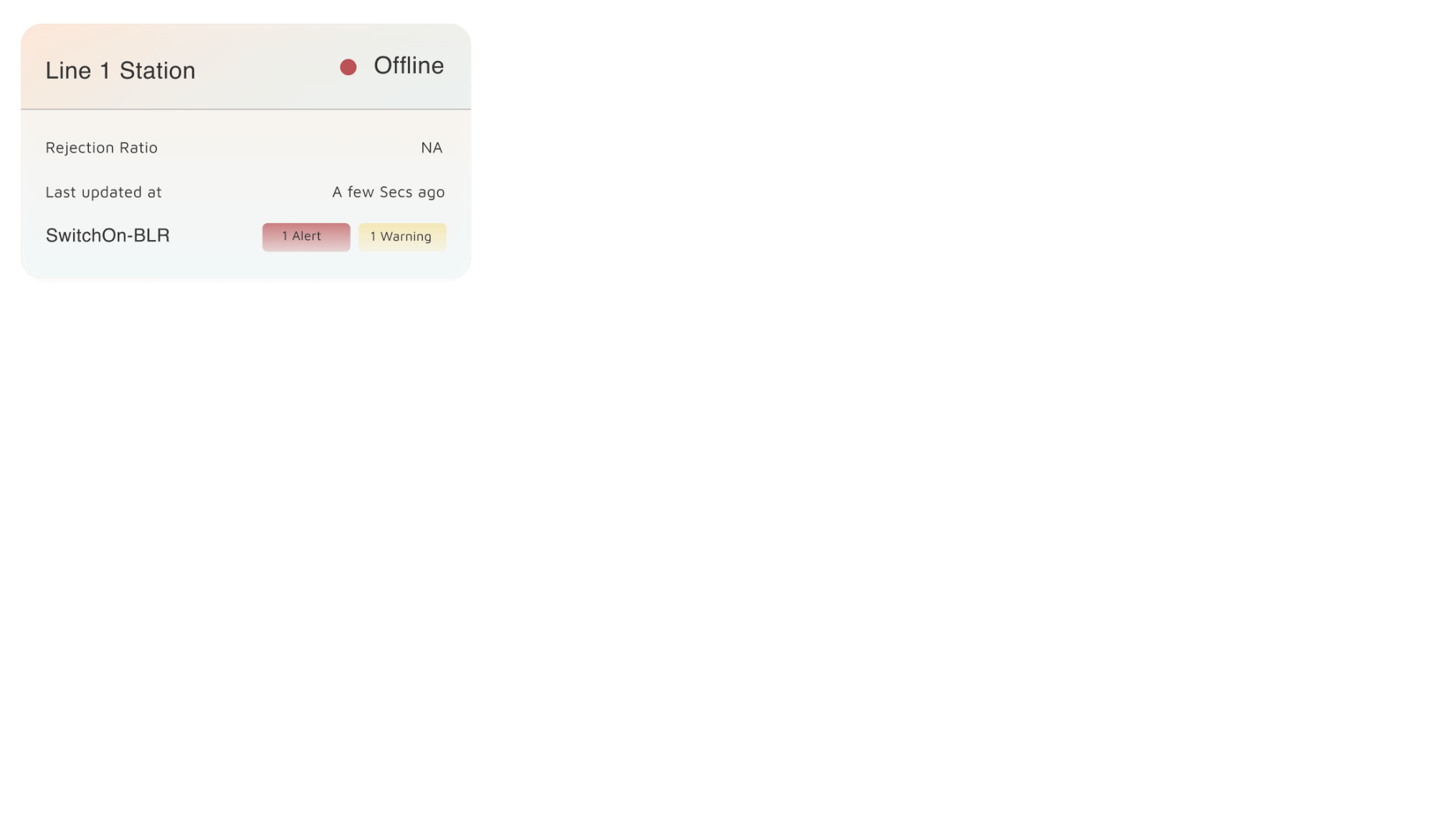

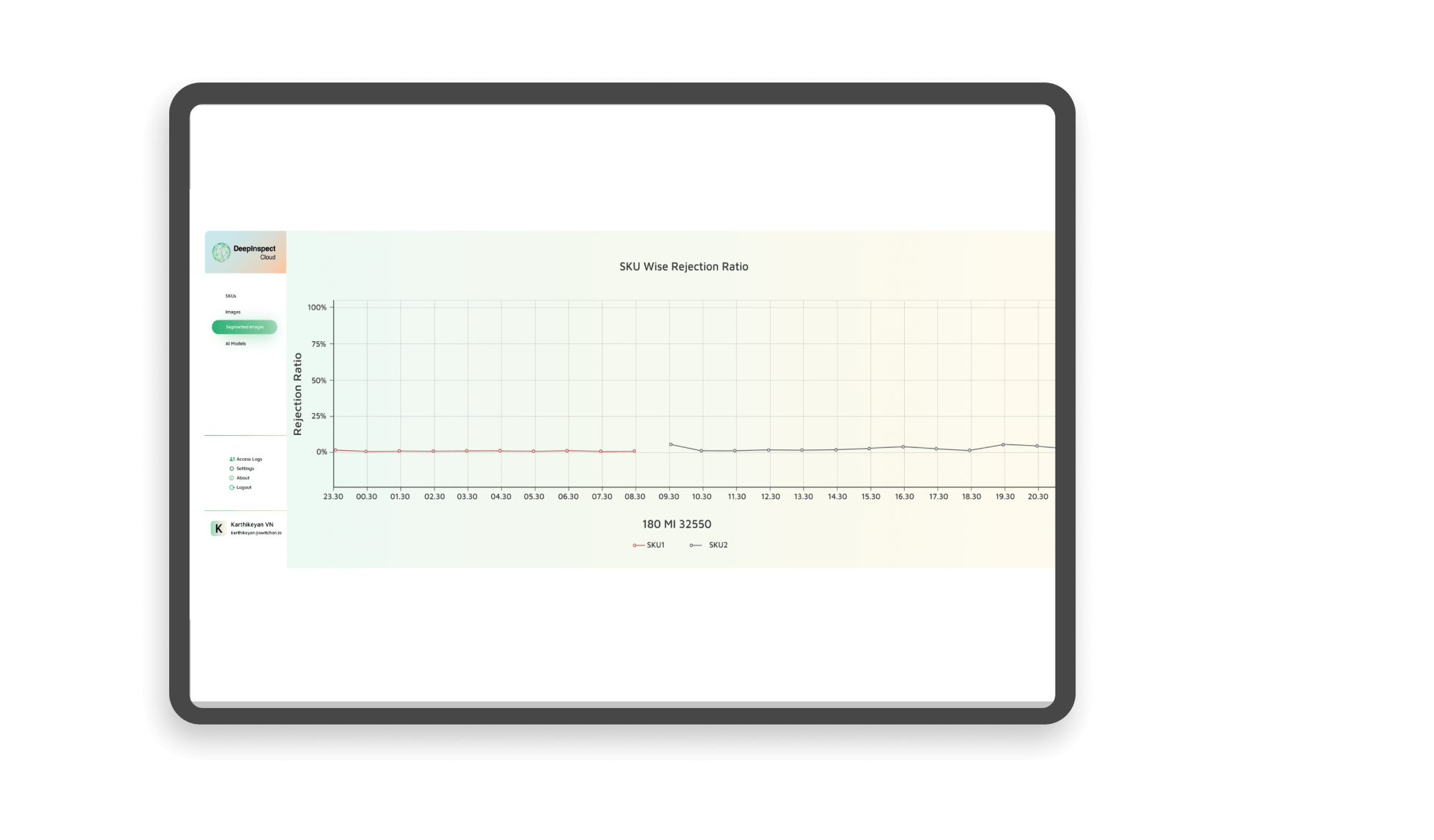

DeepInspect® Analytics

Monitor, root cause and improve

Industry 4.0 enabled system with complete analytics of all inspected products

Analyze rejection ratio trends and check images to root cause production and machine issues

Integrate feature rich APIs into existing analyics for a more comprehensive reporting

System Engineering + Research Based Approach

At SwitchOn,Inc, we’ve embraced a hybrid methodology that merges Research and System Engineering

By combining top-tier industrial-grade hardware with DeepInspect® (advanced AI research, hardware optimizations, and applications), we achieve unmatched reliability and accuracy

Industrial Grade Deployment

Automate Tasks Focus on Innovation with

DeepInspect®

Our vision is to enhance human capabilities by providing tools that amplify their productivity through AI. Specifically in quality inspection, DeepInspect automates the most mundane tasks, freeing plant and quality operators to focus on innovation

Exceptional Technology, Unmatched Support:

Operational 24/7/365

Great technology is only as good as the support behind it. We take pride in building an exceptional support team and developing robust support tools, ensuring your system is operational 24/7/365

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC

DeepInspect supports inspection speeds of up to 1000+ parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

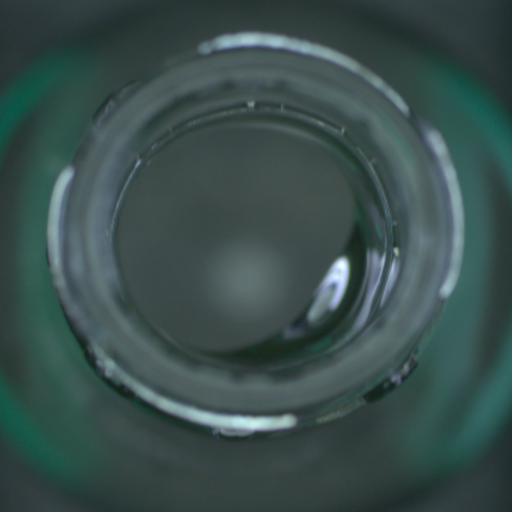

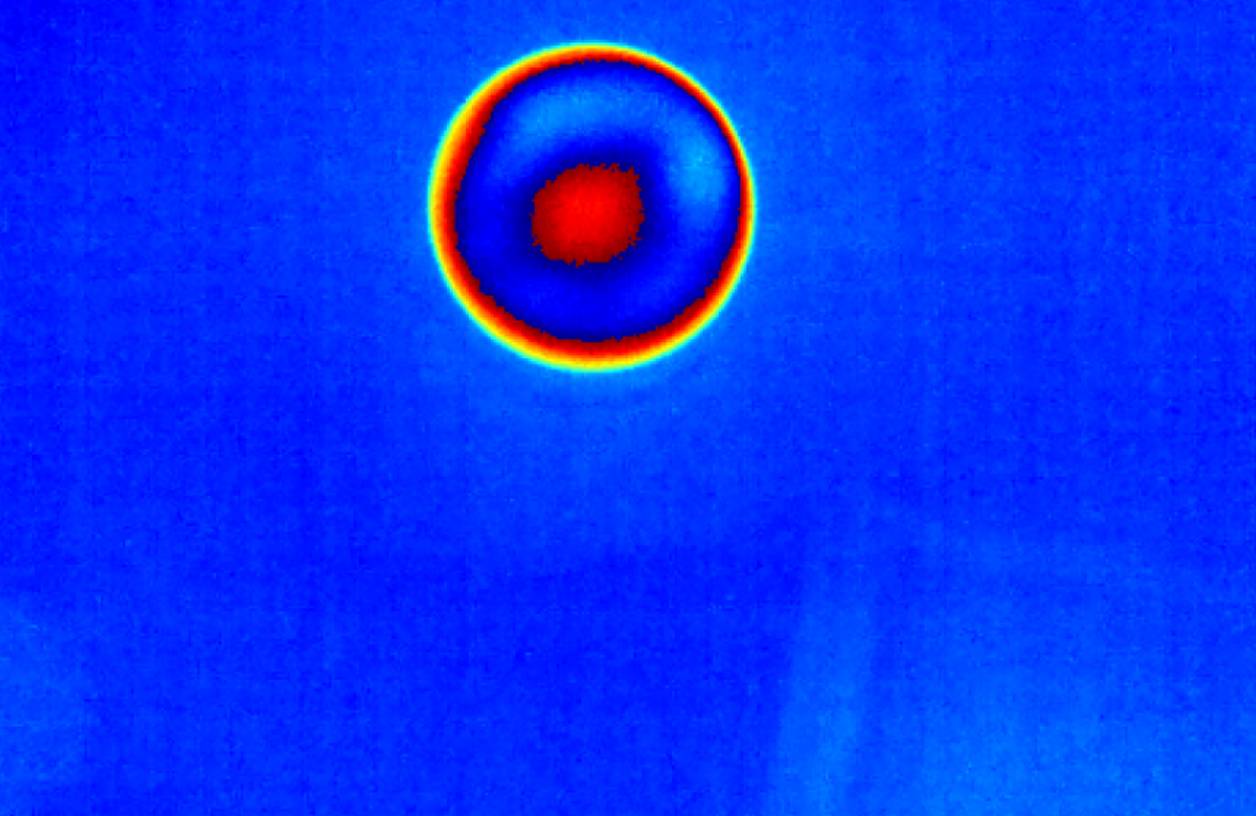

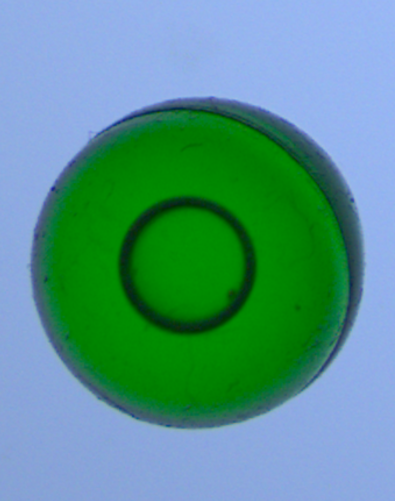

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our case studies to learn more.