Reimagining 360° Cap Inspection with DeepInspect

Reimagining 360° Cap Inspection with DeepInspect®

Related Articles

Introduction

Caps are more than just closures — they are the first line of defense in product safety and integrity, especially in industries like pharmaceuticals, food, and beverages. A defective cap can lead to contamination, spoilage, or even dangerous leaks, risking consumer safety and brand reputation. As production volumes scale, so does the importance of an efficient, accurate, and cost-effective inspection system. That’s where DeepInspect steps in, transforming cap inspection with AI and advanced optics.

How Are Defects Formed on Caps?

Injection molding issues

Defects such as incomplete fills or warping can occur due to injection molding issues

Mechanical handling

Mechanical handling of caps can result in defects like scratches, dents, or deformation

Printing or Labeling Errors

Defects like, misalignment, smudging, etc. occurs due to print errors

Contamination

Foreign particles adhering to the cap surface causes contamination

360° Cap Inspection Challenges with Traditional AI Systems

Traditional AI-based inspection systems typically rely on 4 or more cameras positioned around the cap. While this may sound comprehensive, several limitations persist:

- Incomplete 360° coverage: Even with multiple cameras, overlapping blind spots can allow defects to slip through.

- High equipment and maintenance costs: More cameras mean more complexity — driving up operational and inspection expenses.

- Accuracy concerns: Inconsistent lighting and camera angles often result in false positives or missed defects.

In short, traditional systems are expensive and still fall short of delivering consistent, reliable results.

The Solution: Cap Inspection Using DeepInspect®

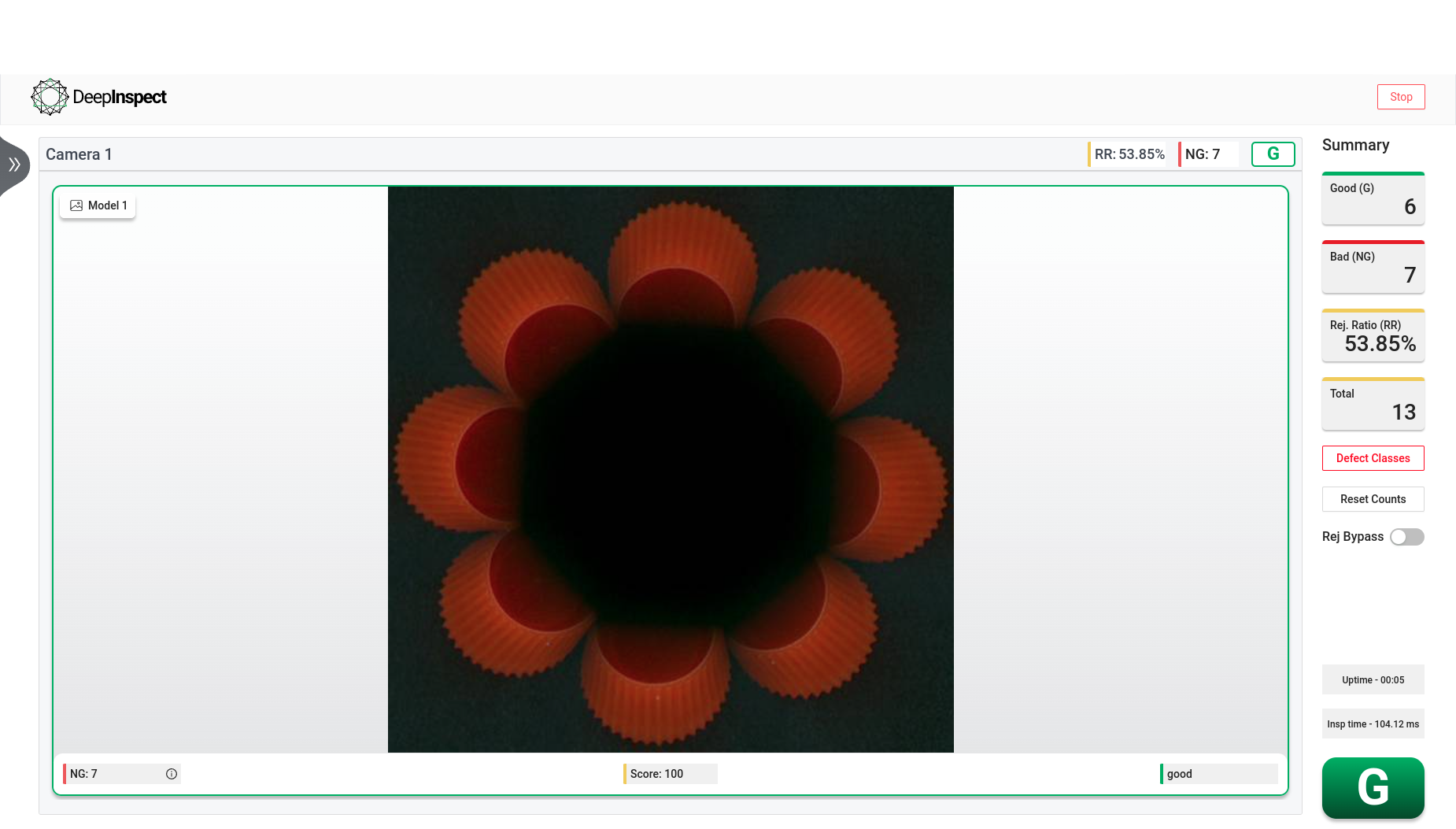

DeepInspect® is an AI powered visual quality inspection software that disrupts traditional 360° cap inspection. Unlike conventional setups that require four or more cameras and still leave gaps in coverage, DeepInspect® uses only two camera system for the inspection. These work in tandem with specialized optics and AI-powered algorithms to deliver full 360-degree inspection. The system can analyze every surface detail with precision, ensuring no area goes unchecked. This drastically reduces hardware complexity and maintenance requirements while enhancing reliability and repeatability.

The result is a high-speed, cost-effective inspection system that delivers 99.5% defect detection accuracy. DeepInspect® help minimize false positives, and ensures that even the smallest defects are identified consistently. With just 2 camera systems and simplified integration, manufacturers benefit from lower setup and operational costs.

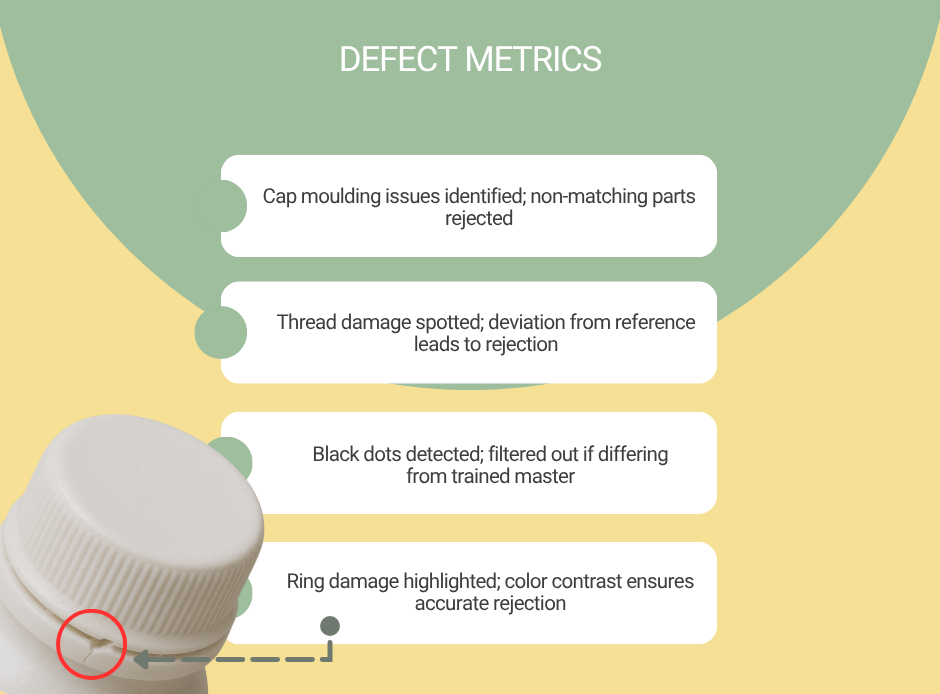

Inspection Coverage: Few Cap Defects Detected by DeepInspect®

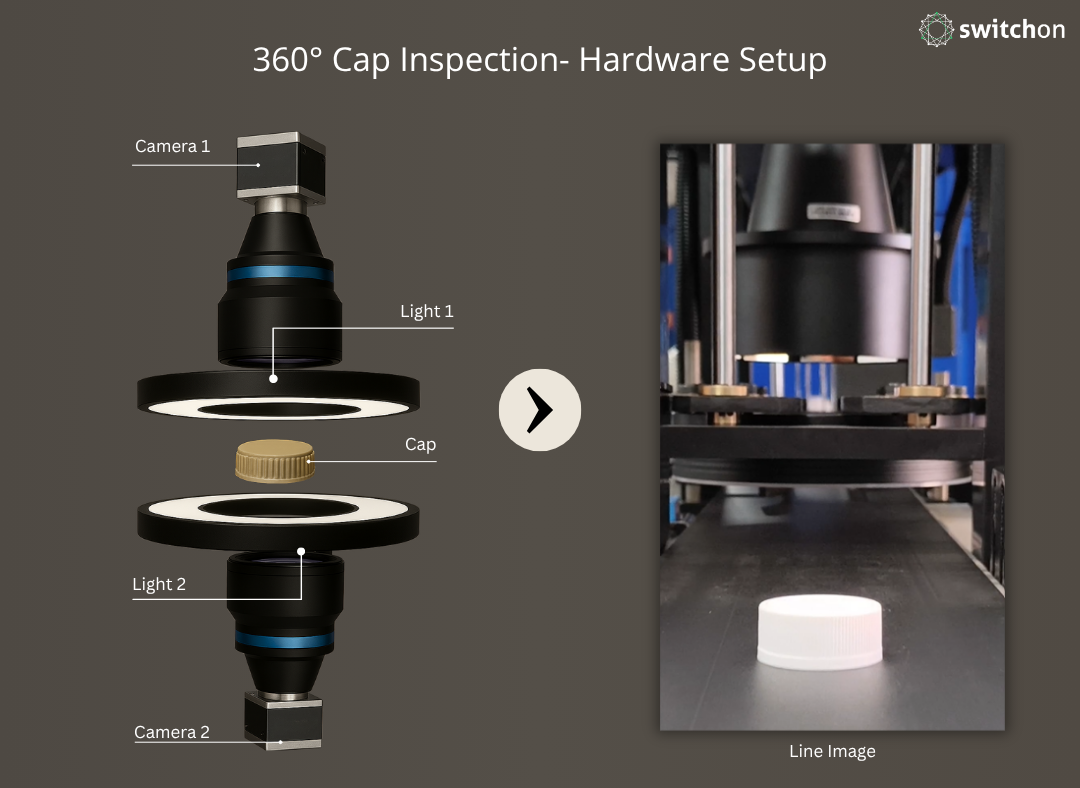

360° Cap Inspection - The Hardware Setup

The setup consists of a dual-camera system — one camera positioned at the top to inspect the outer surface of the cap, and another placed underneath to capture the inner profile. It is powered by an industrial controller, GPU, supported by industrial-grade machine vision lights, high-resolution industrial cameras, and a Mitsubishi I/O module

Why DeepInspect® for Cap Inspection?

- Requires fewer than 200 good images for AI model training

- Model training completes in under 45 minutes

- True 360-degree cap inspection using just 2 camera system

- False positive rate below 0.1%, reducing unnecessary manual checks

- Optimized for fast deployment

- Minimizes inspection infrastructure complexity and costs

- Delivers high-accuracy results suitable for high-throughput lines

Conclusion

DeepInspect® offers a reliable, efficient, and cost-effective solution for 360-degree cap inspection. By replacing complex multi-camera setups with a simplified two-camera system, it delivers complete scap inspection with 99.5% accuracy. The ability to train models with fewer than 200 images in under 45 minutes makes it highly adaptable for fast-paced production environments.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.