Machine Vision for Smartphone Manufacturing

DeepInspect®- AI-powered visual quality software for smartphone & assembly inspection

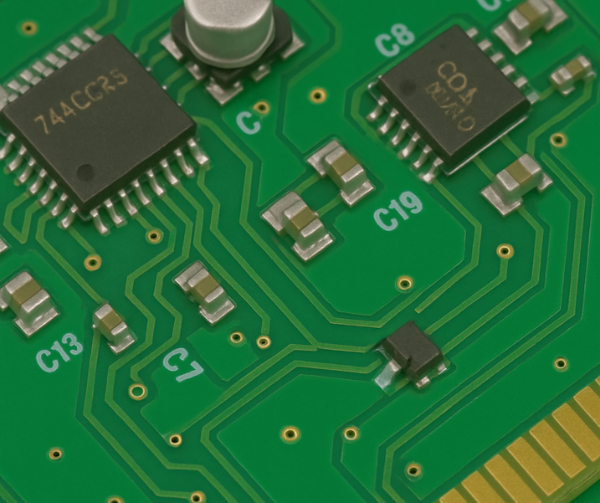

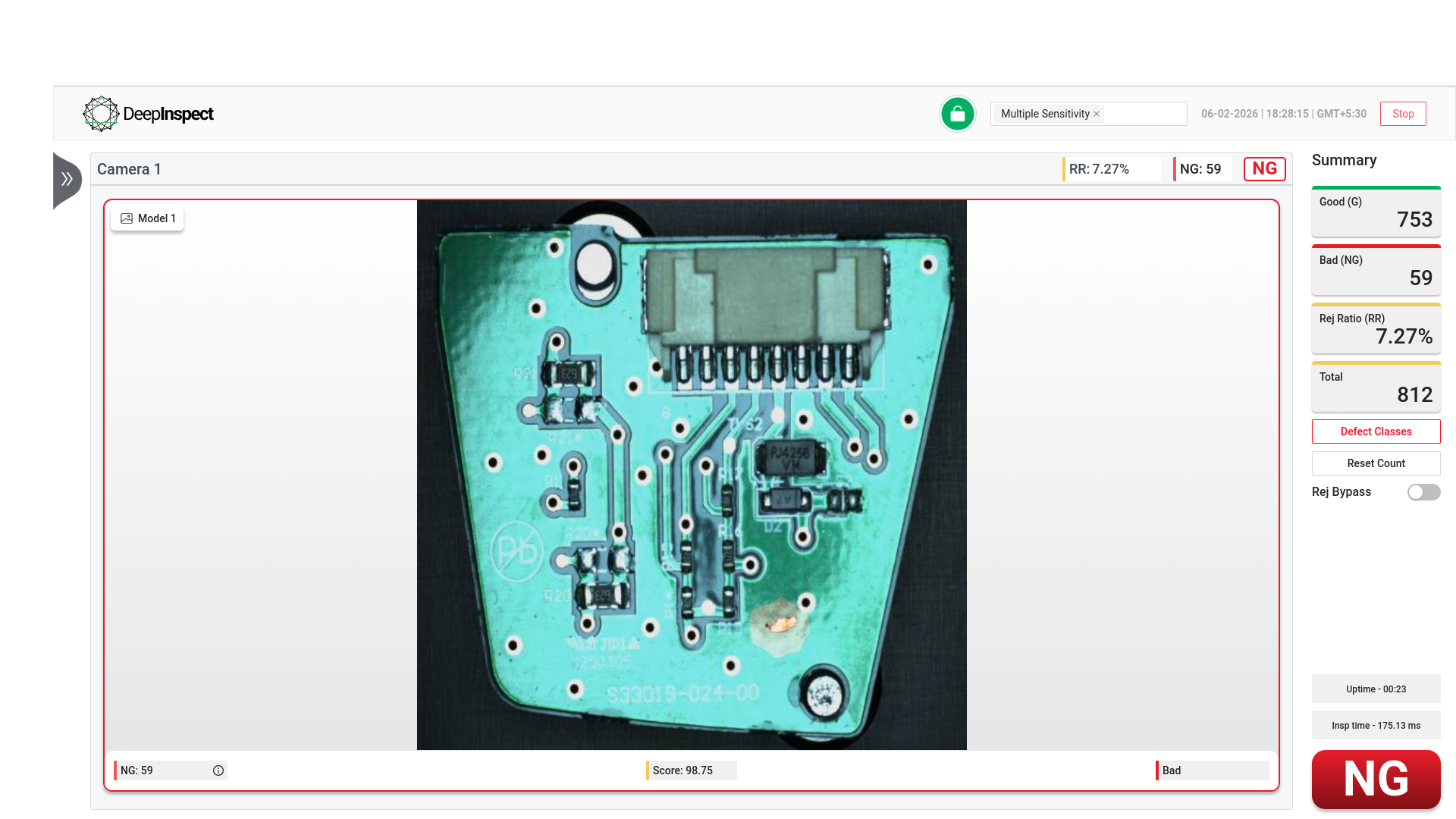

In today’s competitive smartphone market, ensuring zero-defect production is critical. DeepInspect®, an advanced AI-powered smartphone visual quality inspection software, helps manufacturers detect even the most subtle defects across every stage of production — from PCB soldering defect detection to display quality checks and camera module inspection.

Using cutting-edge machine vision for smartphone manufacturing, DeepInspect® automatically identifies issues like dead pixels, backlight bleeding, lens dust, scratches, dents, and housing misalignments in real time. Unlike traditional smartphone quality control systems, which require thousands of images, DeepInspect® delivers 99.5% accuracy with less than 200 good images, reducing false positives to under 0.5%.

With its inline smartphone defect detection capabilities, manufacturers can monitor assembly lines in real time, ensuring consistent quality while reducing manual inspection errors and production costs. Whether it’s camera lens defect detection, battery visual quality checks, or packaging barcode verification, DeepInspect® offers a comprehensive solution to eliminate smartphone defects, enhance productivity, and deliver flawless devices to customers worldwide

APPLICATION

Detect pre-assembly defects like frame warping, glass micro-cracks, and port misalignments

Detect post-assembly defects like dead pixels, camera misalignment, seal failures, etc.

Read and verify serial numbers, IMEI, and barcodes for traceability

Detect Liquid Injection Moulded rubber defects like flash, voids, etc. accurately.

Detect Liquid Injection Moulded rubber defects like flash, voids, etc. accurately.

Impact

DeepInspect® revolutionizes smartphone visual inspection. It offers 99.5% defect detection accuracy

Deep learning based smartphone defect detection system 99.5% Accuracy

Front Glass

Rear Housing

Buttons

Port Openings

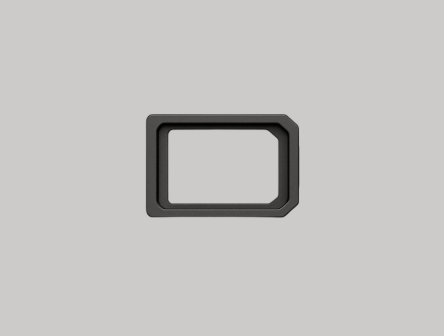

SIM Tray

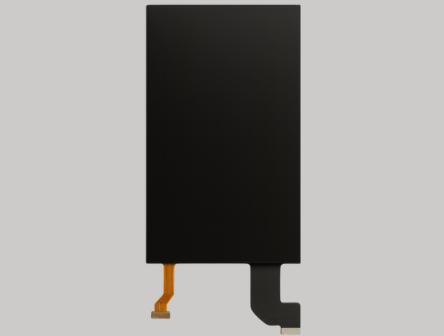

LCD / OLED Panels

Adhesive Placement

Battery Labeling

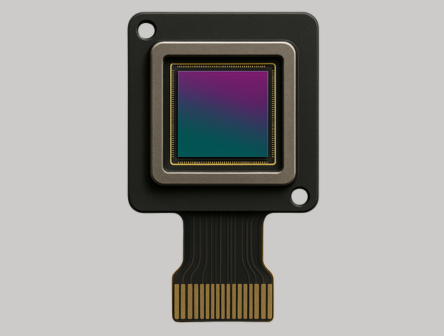

Lens Assembly

Camera Housing

Flash Assembly

Image Sensor Module

Device Frame

Speaker Grills

IMEI Labels

PCB

Inline defect detection for smartphone Assembly Lines

DeepInspect® - Best visual defect detection software for smartphone manufacturers

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

Line Trial in One Day: A complete line trial can be conducted at your plant within a single day

Train AI models with less than 200 good images in under 45 minutes

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in Smartphone defect detection software?

Book a free demo!

Inquiry Form

Mobile phone visual quality inspection is the process of using AI-powered machine vision systems to automatically detect defects in smartphone components such as screens, PCBs, camera modules, batteries, and housings. It helps manufacturers ensure zero-defect smartphone production, reduce manual errors, and improve overall product quality

AI visual inspection improves accuracy and speed by identifying micro-level defects like dead pixels, soldering issues, dust inside camera modules, and housing misalignments. It reduces false positives, cuts inspection costs, and enables real-time inline defect detection, ensuring flawless devices reach customers.

Key parts include LCD/OLED displays, PCBs, camera lenses, batteries, connectors, SIM trays, charging ports, speaker grilles, and packaging labels such as IMEI numbers and barcodes. Each component is checked for cosmetic, structural, and functional defects

AI systems like DeepInspect® use deep learning models trained on fewer than 200 good images to identify defects in milliseconds. The system inspects 1,000+ parts per minute with 99.5% accuracy, providing actionable data through real-time dashboards.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

A line demo for DeepInspect can be conducted within a day