AI-Powered machine vision for cosmetic tube quality inspection

DeepInspect® – Cosmetic tube finishing and surface quality control software

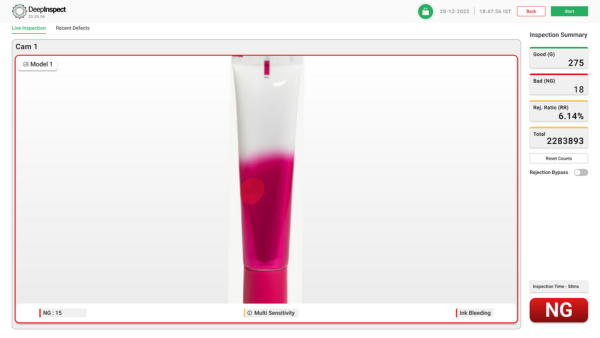

Cosmetic manufacturers rely on flawless packaging, and even micro-level scratches, dents, punctures, or crimp defects can damage brand perception. DeepInspect® delivers an AI-powered quality inspection system designed specifically for cosmetic squeeze tube inspection, offering automated visual inspection, real-time defect detection, and zero-defect manufacturing capability. Using advanced AI-powered vision systems, DeepInspect® identifies scratches, dents, scuff marks, punctures, crimp tears, squeezed crimps, and visible silver on ABL/PBL tubes with unmatched accuracy.

Its deep-learning engine performs high-speed cosmetic tube surface inspection, detecting subtle defects that traditional machine vision and manual QC often miss. With DeepInspect®, manufacturers achieve reliable tube surface quality control automation, ensuring consistent inspection across all lines, shifts, and batches.

From cosmetic packaging inspection to sealing verification and print quality checks, DeepInspect® enables a fully automated, non-contact, 360° inspection workflow—helping cosmetic brands eliminate defects early and deliver perfect, premium tubes every time.

USECASE

Defects Detected by DeepInspect®

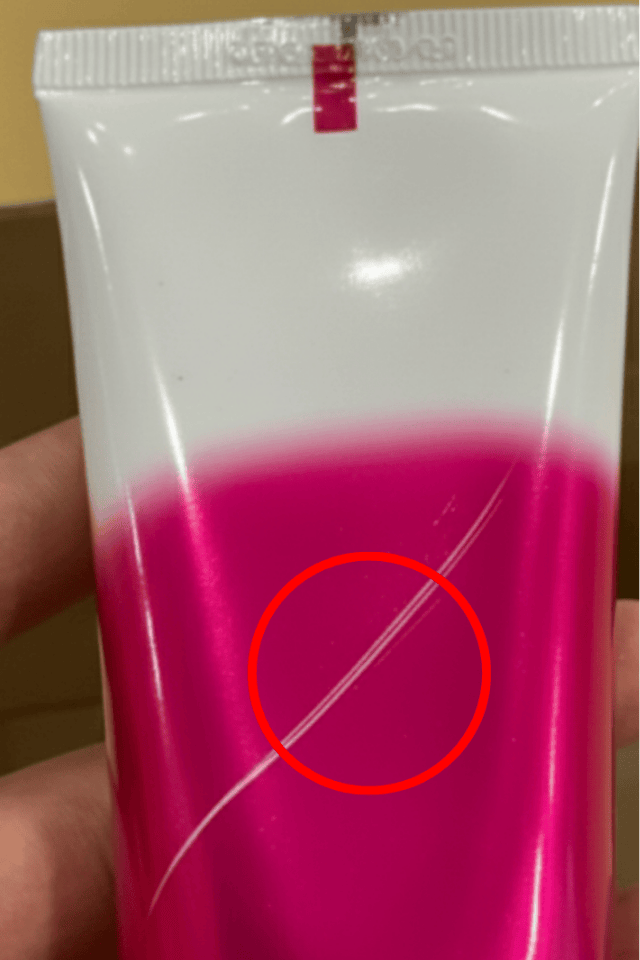

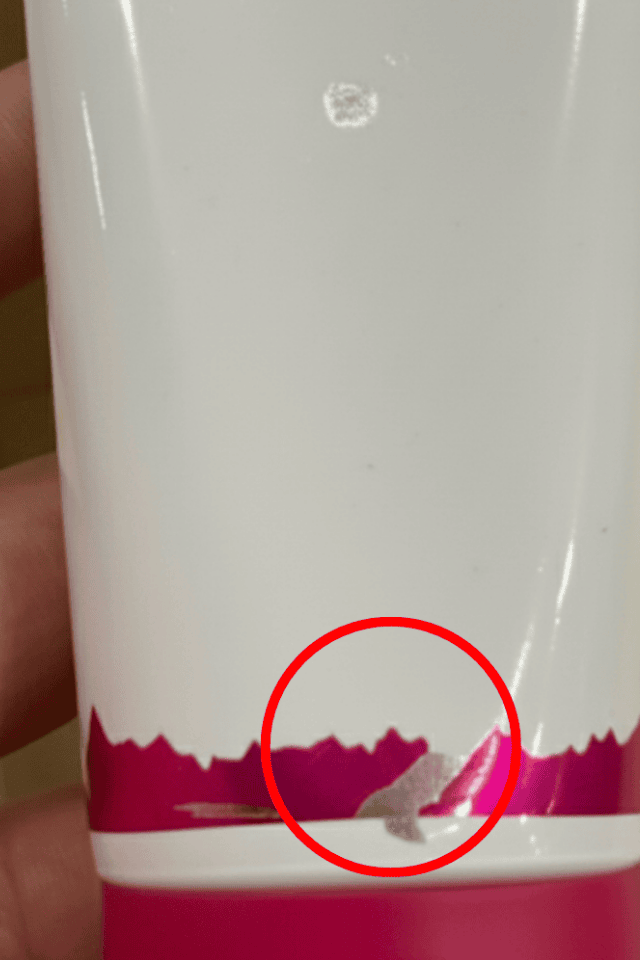

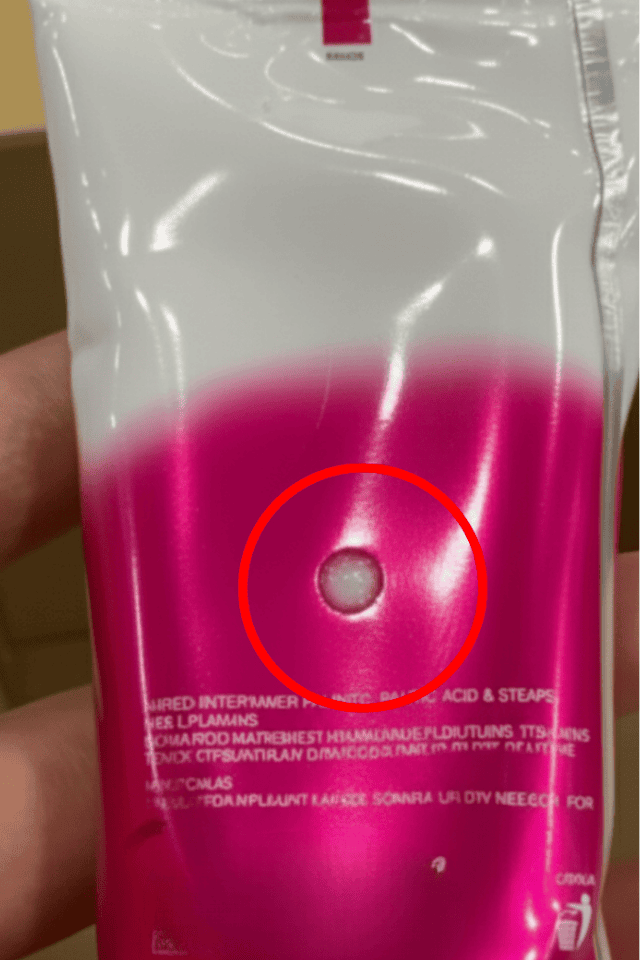

DeepInspect® detects all surface and dimensional defects, such as:

Identifies subtle body and surface defects quickly and accurately across all cosmetic tubes inspections

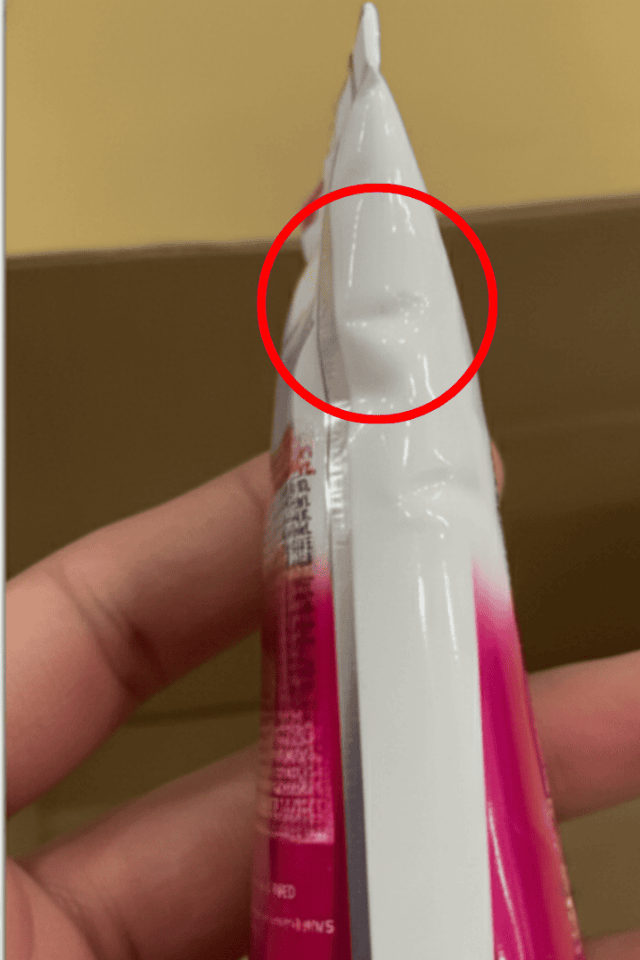

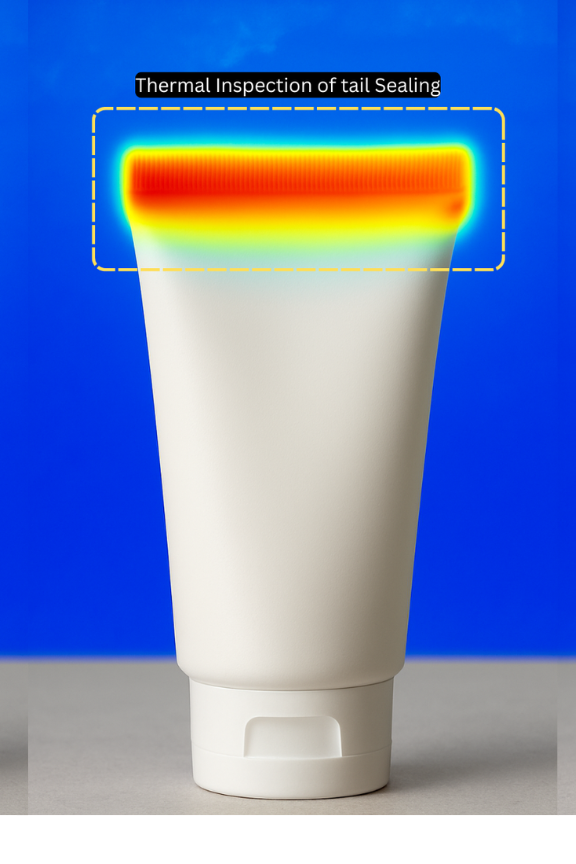

Detects all crimp and sealing defects, including tears, weak seals, folds, and squeezed crimps

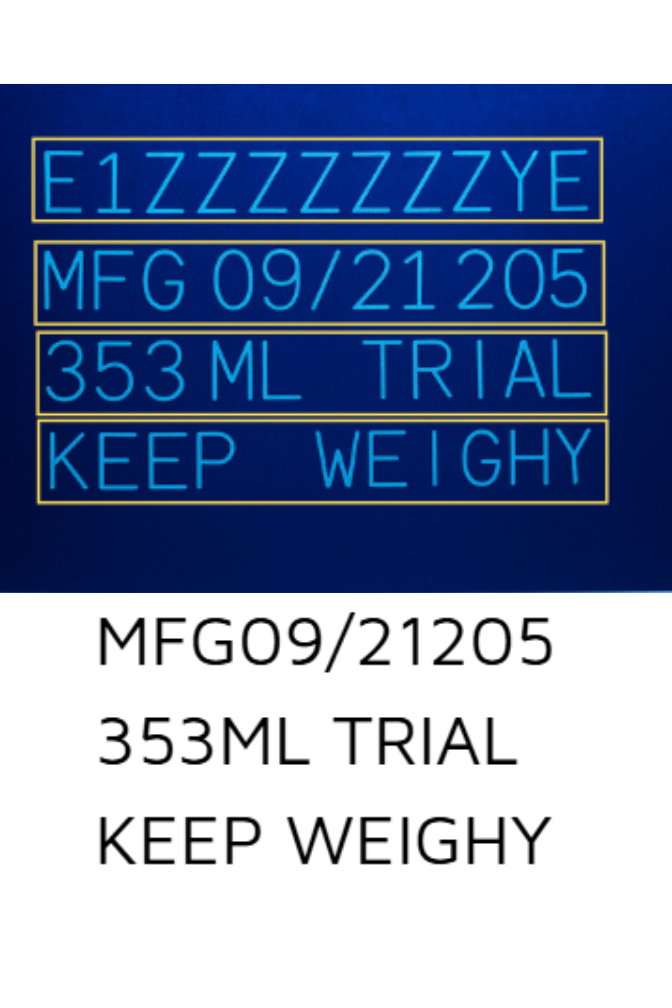

Ensures accurate reading and verification of all printed text, codes, and characters

Identifies misaligned, shifted, or incomplete artwork to maintain perfect visual presentation

Deep learning anomaly detection for FMCG packaging

Puncture Defects

OCV/OCR

Hairline Scratches

Artwork Defect

Visible Silver Defect

Air Traps

Squeezed Crimps

Sealing Defects

DeepInspect®- Best cosmetic tube scratch and dent detection software

Ensure zero-defect HDPE tubes manufacturing

High-speed inspection system for cosmetic tubes

Why DeepInspect®

99.5% Inspection Accuracy: DeepInspect® delivers consistent, high-speed inspection accuracy of 99.5%, setting new benchmarks for reliability in automated quality control

Less Than 200 Good Images for Model Training: DeepInspect® requires fewer than 200 good images to learn, adapt, and begin accurate inspection with minimal setup effort

Model Training in Under 45 Minutes: DeepInspect® enables model creation and fine-tuning in under 45 minutes, reducing downtime and maximizing productivity

1000+PPM: High-speed inspection, detecting 1000+ parts per minute

End-of-line cosmetic tube inspection with 99.5% accuracy

Our Customers

Trusted by the world’s leading manufacturers to power zero-defect production

Interested in FMCG production line quality control automation?

Book a free demo!

Inquiry Form

Cosmetic tubes can have surface scratches, dents, punctures, air traps, blisters, laminate delamination, artwork shifts, crimp tears, weak seals, and print/lot-code errors.

High-resolution cameras capture the crimp area, and DeepInspect-like AI models learn the shape, texture, and brightness of a good seal, flagging half seals, no seals, squeezed crimps, burns, and channel leaks in real time.

OCR (Optical Character Recognition) is used to read printed text such as batch codes, expiry dates, MRPs, and lot numbers on the tube or carton.

Yes. DeepInspect® identifies micro-scratches, dents, pinholes, wrinkles, and deformation that are nearly invisible to manual inspection or traditional rule-based systems.

Yes. DeepInspect® removes human subjectivity by providing consistent, 24/7 automated inspection with far better repeatability, ensuring no sealing, surface, or print defect reaches the market.

DeepInspect® requires fewer than 200 good images for model training, significantly reducing setup time for AI defect detection.

No. DeepInspect® uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection

DeepInspect® supports high-speed inline inspection for 1000+ tubes per minute, ensuring real-time rejection and zero disruption to production.

Yes. DeepInspect® uniquely integrates surface defect detection and print verification into a single AI-powered platform, delivering complete cosmetic tube quality assurance.