Syringe and Needle Quality Inspection for Pharma Industry

DeepInspect, the syringe and needle defect detection software, provides comprehensive needle defect detection and syringe inspection for high-quality control. The system ensures syringe quality control by identifying defects in both syringe barrels and needles. It excels in automated syringe inspection, detecting needle misalignment, needle tip damage, and needle surface quality inspection. With advanced syringe dimensional inspection, it accurately detects syringe surface defects, needle tip inspection, and needle coating defects. Syringe packaging inspection and batch code verification ensure accurate labeling and packaging. Syringe and needle defect detection software- DeepInspect guarantees needle quality assurance, providing real-time analysis and improving manufacturing precision. Automated defect detection for syringes ensures high efficiency and safety in medical device production.

APPLICATION

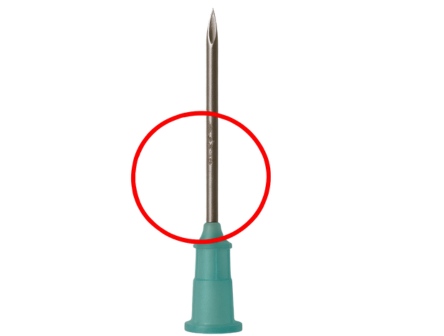

Detect needle defects like misalignment, tip damage, surface imperfections, etc.

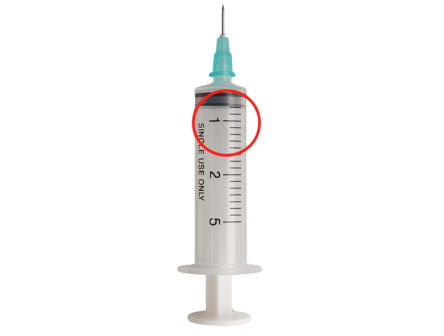

Flag barrel defects like cracks, chips, scratches, dimensional inaccuracies, surface imperfections, etc.

Detect plunger defects like sealing issues, warping, surface defects, irregularities, deformation etc.

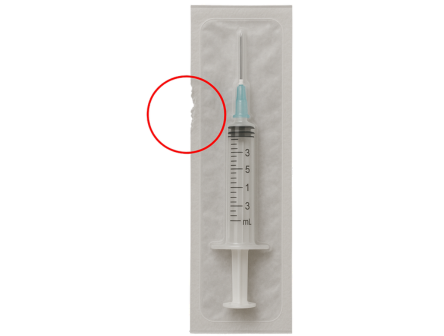

Identifies packaging defects like torn packaging, misaligned labels, incorrect batch codes, etc.

Impact

Using DeepInspect in syringe and needle quality inspection ensures 99.5% accuracy and less than 0.5% false positive rate. It effectively detects needle misalignment, surface imperfections, and dimensional inaccuracies, enhancing efficiency, safety, and compliance with precise needle tip inspection and syringe packaging.

Detect all kind of Syringe &Needle defects with 99.5% Accuracy

Syringe barrel defects

Syringe needle defects

Syringe plunger defects

Syringe packaging defects

Interested in Streamlining Syringe Quality Inspection Process?

Drop us a line or shoot us an email

Inquiry Form

Syringe and needle defect detection software DeepInspect is used to automate the inspection process, detecting issues like misalignment, cracks, and surface imperfections in syringes and needles

DeepInspect uses advanced AI algorithms to detect defects in needle tips, such as damage, misalignment, and coating inconsistencies

Automated syringe inspection enhances efficiency by quickly detecting syringe barrel defects, needle misalignment, and packaging issues. It reduces human error and ensures high precision in manufacturing processes, saving time and cost

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for defect detection

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection system

A line demo for DeepInspect system can be conducted within a day, showcasing its fast implementation and ease of use

DeepInspect is ideal for industries such as automotive, electronics, and consumer goods manufacturing, providing automated quality inspection for high-precision plastic molded parts.