AI- Powered Thermal Inspection using DeepInspect

AI- Powered Thermal Inspection using DeepInspect

Related Articles

Introduction

Traditional vision inspection systems have long been the go-to method for detecting defects in aluminum sealings. However, these systems focus on visible changes and follow rigid, rule-based thermal criteria, making them less effective at identifying more complex or hidden issues. As a result, defects often go undetected, leading to inconsistent quality control and time-consuming setup processes.

DeepInspect: AI-Powered Thermal Inspection Software

DeepInspect represents the next generation of thermal inspection software, utilizing AI to provide unparalleled accuracy in defect detection. Unlike conventional systems that rely solely on visible changes or specific temperature thresholds, DeepInspect harnesses the power of AI to analyze infrared camera images and detect defects that might be missed by traditional methods. With a detection rate of over 99.5% and false positives under 1%, DeepInspect ensures that defects such as underheating, burnouts, and cut foils are detected with precision, enabling more consistent quality control across production lines.

How DeepInspect’s AI- Powered Thermal Inspection works?

The DeepInspect thermal inspection setup consists of the following components:

DeepInspect Software

Industrial Infrared Camera

Industrial Lighting

PLC (Programmable Logic Controller)

Industrial Controller

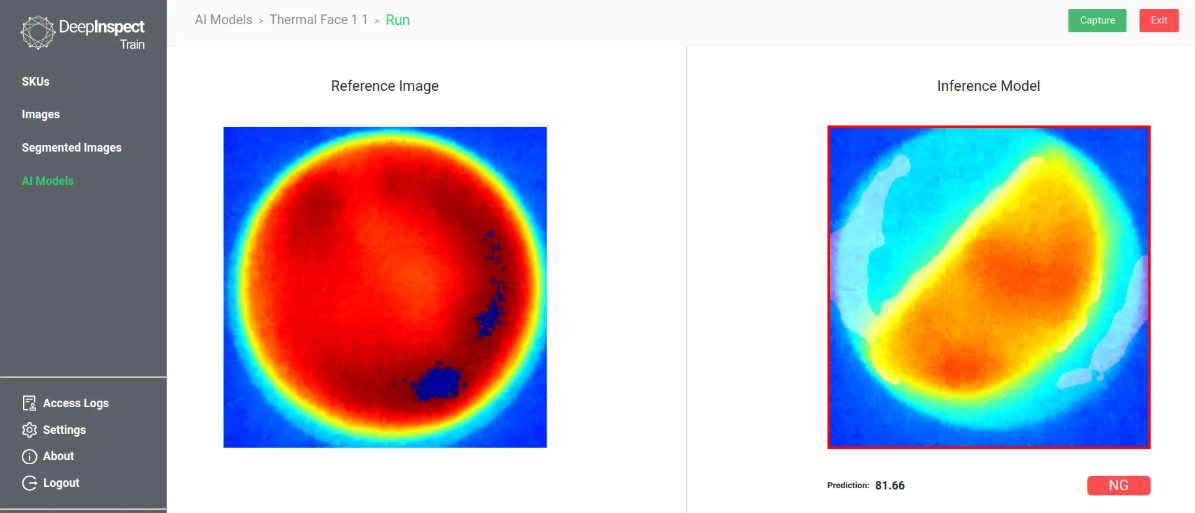

As the sealed bottles pass through the DeepInspect thermal inspection setup, positioned near the packaging department, the infrared camera captures thermal images of each bottle. The DeepInspect software then compares these images to a reference model, trained using fewer than 200 high-quality sealing samples. If any variations are detected, the system triggers a rejection mechanism, automatically removing defective products from the production line.

Why DeepInspect Over Traditional Rule-based Thermal Inspection Systems?

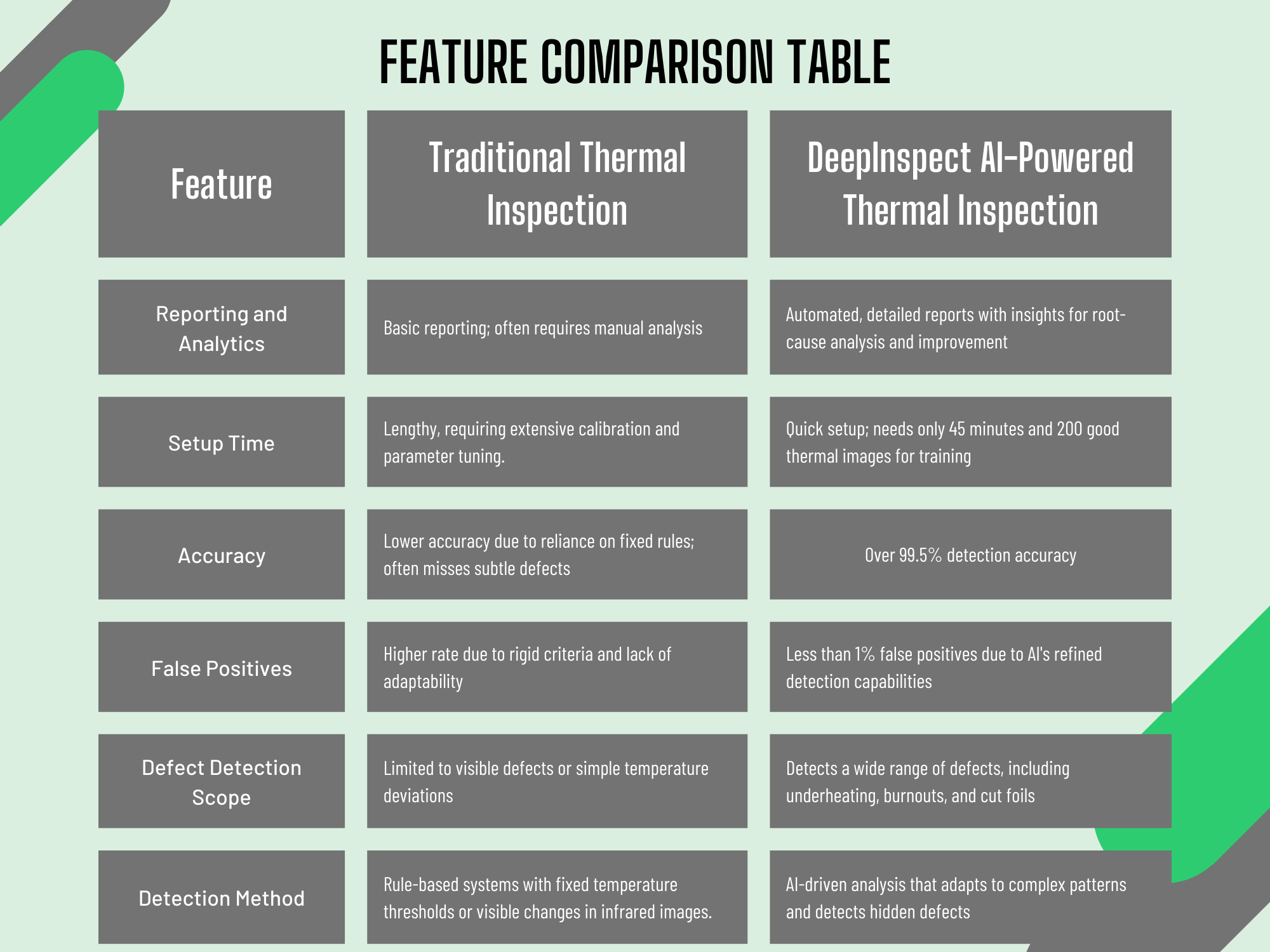

Traditional rule-based thermal inspection systems have long been used but come with limitations like missed defects and poor adaptability. DeepInspect, with AI technology, overcomes these issues by offering superior accuracy and flexibility.

Here’s a quick comparison between the two:

Advantages of DeepInspect Thermal Inspection Software

Delivers over 99.5% defect detection accuracy with less than 1% false positives, ensuring exceptional reliability.

Offers fast setup and high repeatability, making DeepInspect an efficient and dependable solution.

Capable of detecting a broad range of defects, including cut foils, underheated seals, burnouts, and missing seals.

Processes images with precision, delivering consistent, stable results that enhance quality inspection and boost operational efficiency.

Conclusion

DeepInspect surpasses the limitations of traditional rule-based systems, offering unparalleled accuracy of over 99.5%, efficiency, and adaptability. With faster setup times, consistent defect detection, and automated insights, DeepInspect helps manufacturers improve quality control and streamline production processes, setting a new standard in thermal inspections.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Learn More?

Download the full use case below!