AI Powered vial quality inspection for Pharma

DeepInspect® is an FDA CFR Part 11-compliant AI-powered vial inspection software designed for pharmaceutical manufacturers seeking reliable and automated visual inspection of parenteral vials. It performs 360-degree vial inspection without any orientation requirement and detects critical glass defects such as chips, cracks, scratches, and delamination, ensuring container integrity. DeepInspect also identifies foreign particles like fibers, dust, or metal within the vial, protecting sterility. Its precision algorithms monitor fill-level defects, flagging underfills and overfills. For packaging assurance, it detects seal defects including loose crimps, misplaced stoppers, and bent caps, as well as labeling defects like missing, skewed, or smudged labels. DeepInspect offers a next-gen, AI-enabled vial defect detection solution—delivering accuracy, compliance, and reduced quality control costs.

APPLICATION

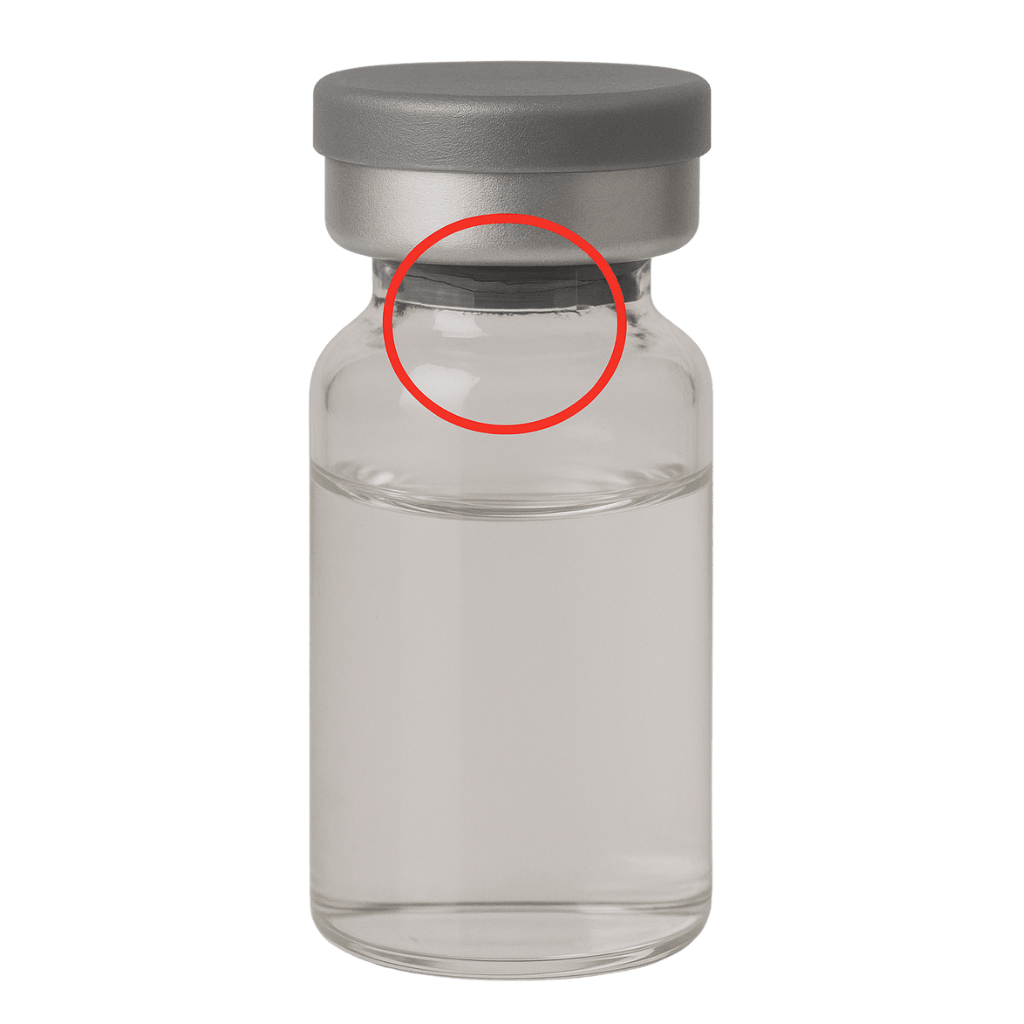

Detects micro-level scratches and cracks on glass vial surfaces precisely

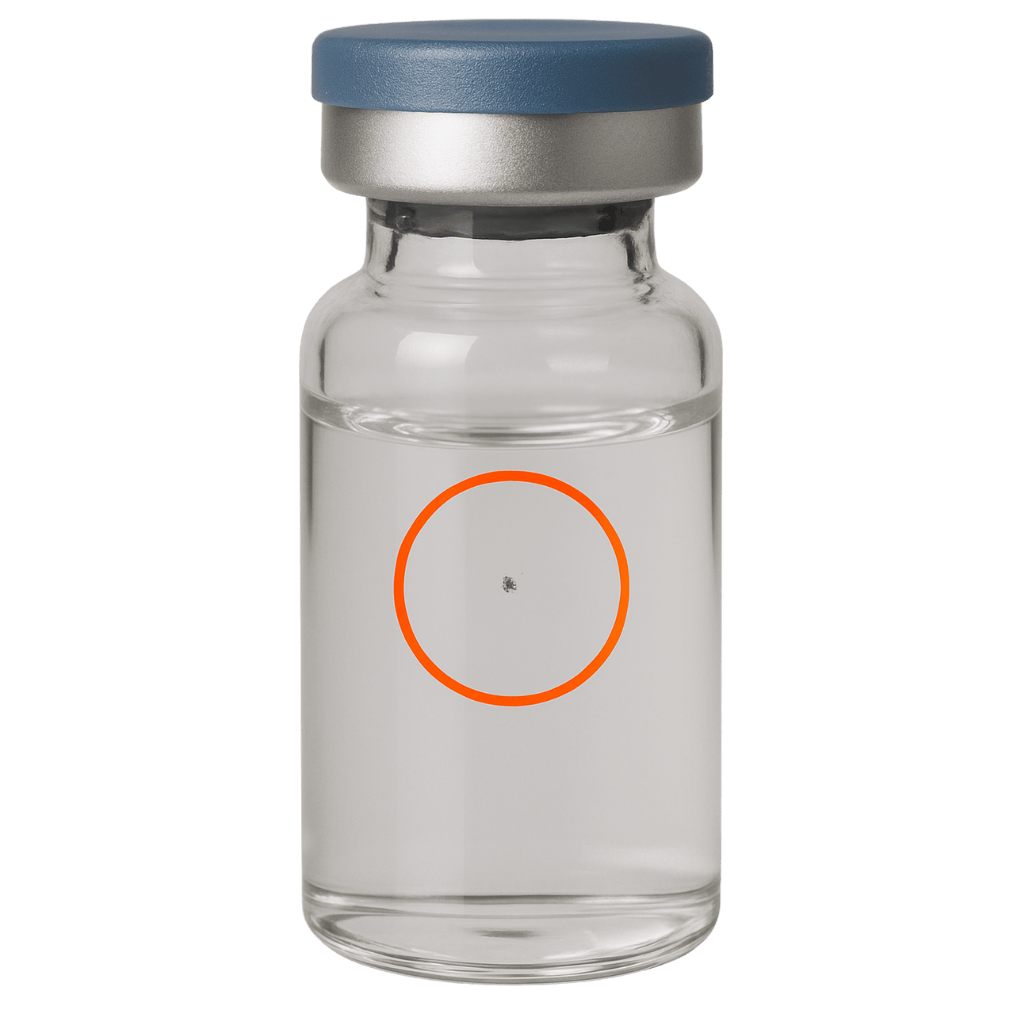

Identifies foreign particles like dust or fibers inside sealed vials

Detects fill-level defects, including underfilled or overfilled vials instantly

Detects labeling defects including OCV/OCR accurately

Impact

With less than 200 good images required for training, DeepInspect delivers 99.5% inspection accuracy in AI-powered vial inspection. It ensures reliable automated visual inspection of parenteral vials, reducing false rejects, manual errors, and costs—while meeting strict pharmaceutical quality control standards

Automated Visual Inspection of Vials with 99.5% Accuracy

Vial Scratches/ Chips etc.

Foreign Particles in Vials

Fill-Related Vial Defects

Vial Sealing Defects

Interested in Streamlining Vial Quality Inspection ?

Book a Free Demo

Inquiry Form

AI-powered vial inspection uses deep learning algorithms to detect defects like cracks, scratches, fill level errors, and foreign particles in pharmaceutical vials with high accuracy and speed

Automated visual inspection systems eliminate human errors, detect micro-level defects, and ensure compliance with pharmaceutical standards—enhancing overall vial quality and reducing rejection rates

DeepInspect identifies glass defects such as scratches, chips, cracks; fill-level issues; foreign particles; sealing faults; and labelling errors, delivering 99.5% inspection accuracy

FDA CFR Part 11 compliance ensures that vial inspection software meets regulatory standards for electronic records and signatures, critical for pharma manufacturing traceability

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect requires fewer than 200 good images for model training, significantly reducing setup time for defect detection

No. DeepInspect uses unsupervised AI, eliminating the need for NG images in training.

Model training is completed in less than 45 minutes, allowing rapid deployment of vision inspection system

A line demo for DeepInspect system can be conducted within a day, showcasing its fast implementation and ease of use