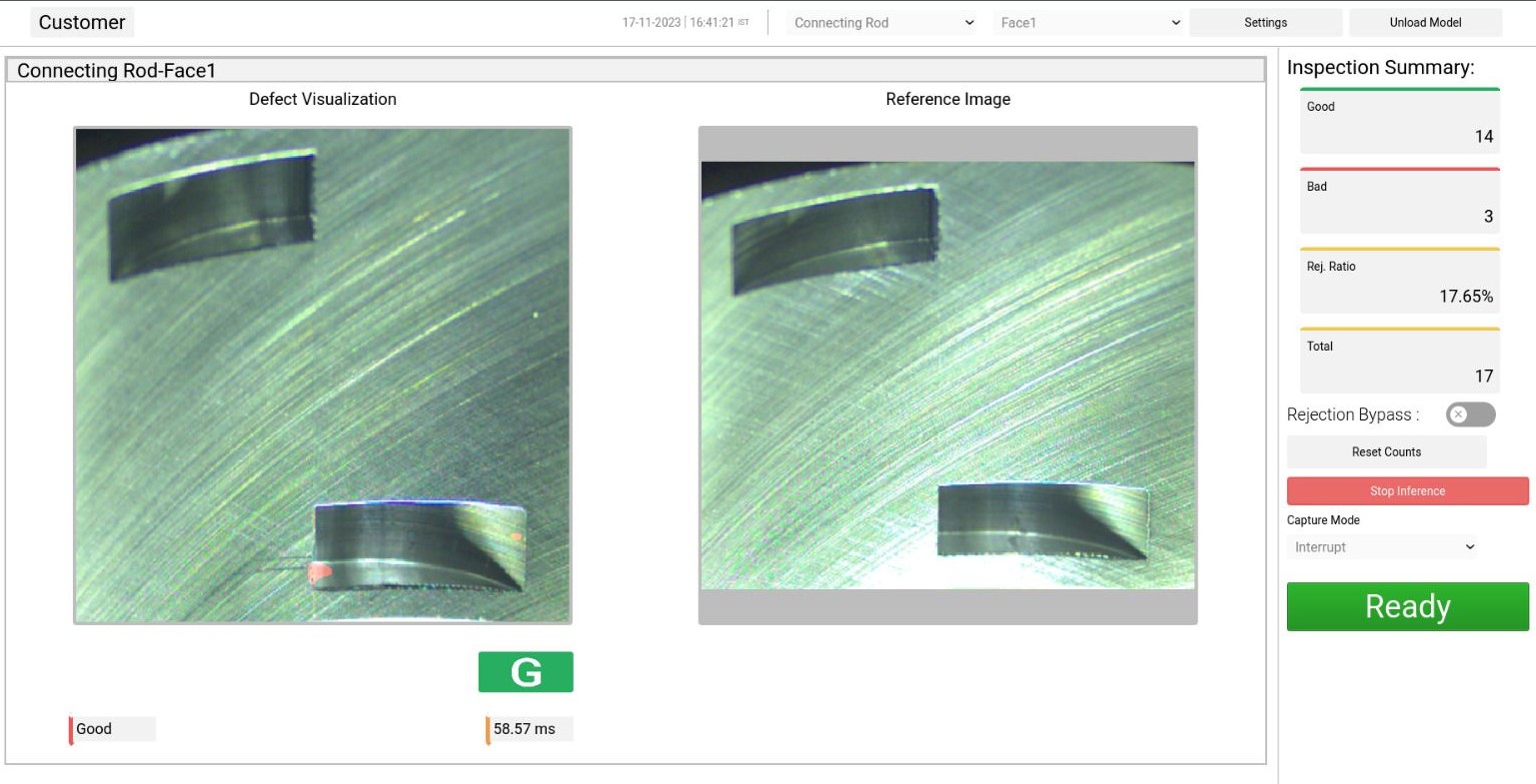

Robotic Inspection of Engine Part- Connecting Rod

Robotic Inspection of Engine Part

Related Articles

How a Renowned Auto Component Manufacturer Harnessed DeepInspect® to Eliminate Defects in Their Connecting Rods

Surface defects on machined parts can jeopardize the entire production line and tarnish your reputation. This was a real challenge for our customer, a renowned name in engine component manufacturing.

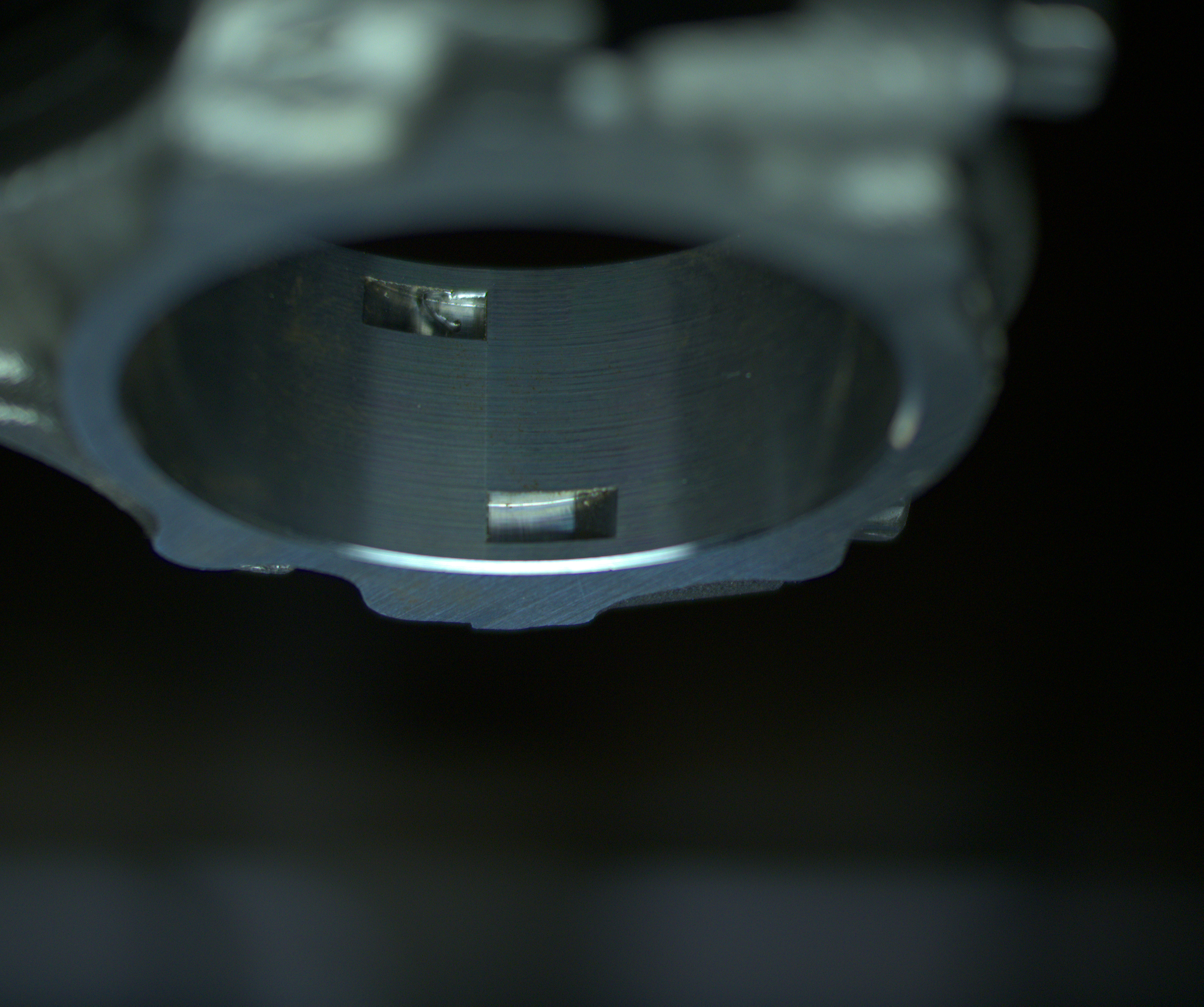

They were facing challenges with surface defects on their connecting rods,also known as conrods- which threatened the quality and reliability of their products. The presence of burrs, scratches, and other surface imperfections not only risked the functionality of the connecting rods but also risked tarnishing their hard-earned reputation for excellence in manufacturing.

Our customer has been delivering top-notch engine components to a wide range of automotive customers including Bajaj, Suzuki, Volkswagen etc. And any compromise on quality was simply unacceptable.

They needed a solution that could reliably detect even the most minor defects without causing unnecessary interruptions to their production line. That’s when they discovered DeepInspect®– AI visual inspection system for manufacturers.

The Setup

The AI- Powered Visual inspection setup consisted of:

DeepInspect® Pro

Fanuc robotic arm

Basler acA2440-35uc Camera

Mitsubishi PLC

TMS industrial machine vision lights

Controller with i5 and Nvidia GPU

Integration with existing automation system

Here’s how the setup works:

The robotic arm picks up each connecting rod and brings it to the DeepInspect® inspection station. The station, equipped with an industrial camera and optimal lighting, performs a thorough scan of the connecting rod. The DeepInspect AI algorithms analyze the images in real-time, identifying any visual defects. Once inspected, the robotic arm places the rod onto a different line, ensuring that only defect-free parts proceed further in the production process.

The Impact

The implementation of AI defect detection system brought immediate and significant improvements to our customer’s production line. With this seamless integration, they were able to identify a vast array of visual defects, including burrs, scratches, and surface imperfections, with remarkable precision.

Our customer was also able to detect manufacturing defects like burrs that are as small as 150 microns and other visual defects within the dual slots of the connecting rod with an impressive 99.5%+ accuracy. This level of precision was achieved by training the DeepInspect® AI model with fewer than 200 good reference images. The training of the DeepInspect® model only took just 45 minutes. This rapid setup time ensured that our customer could integrate the system without significant downtime, further enhancing their production efficiency.

Beyond defect detection, our customer was also able to gather comprehensive quality reports and analytics using DeepInspect®. Decision-makers are able to access automated and downloadable reports, which include detailed defect classifications. This feature simplifies root-cause analysis, allowing our customer to address underlying issues promptly and effectively. The insights provided by DeepInspect® enable continuous improvement in their manufacturing processes, leading to even higher standards of quality and reliability.

Conclusion:

Our customer’s production line is now smoother, faster, and defect-free, thanks to DeepInspect®. The efficiency gains have also translated into cost savings and increased customer satisfaction.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.

Curious to Know More?

Download the full case study and explore how our customer leveraged DeepInpsect to achieve zero defect lines