360° HDPE Tub Inspection Without Orientation

360° HDPE Tub Inspection Without Orientation Requirement

Related Articles

Introduction

High-Density Polyethylene (HDPE) tubs are a cornerstone of the FMCG industry, used extensively for packaging food items like instant noodles, sauces, and snacks. Their durability, lightweight nature, and compliance with food safety regulations make them an ideal packaging choice. However, manufacturers face significant challenges due to defects that can compromise product quality and harm customer satisfaction. This blog explores how the DeepInspect® system, an AI-powered visual quality inspection solution, is revolutionizing HDPE tub inspection and helping manufacturers deliver superior-quality products to customers.

More About HDPE Tubs

HDPE tubs are highly valued for their ability to preserve food quality while being lightweight and durable. Their flexibility in design and excellent resistance to external contaminants make them a preferred choice for a wide range of food packaging applications. However, despite their advantages, defects can arise during production that compromise their performance. Detecting and resolving these issues is crucial for maintaining high product standards in the competitive FMCG industry.

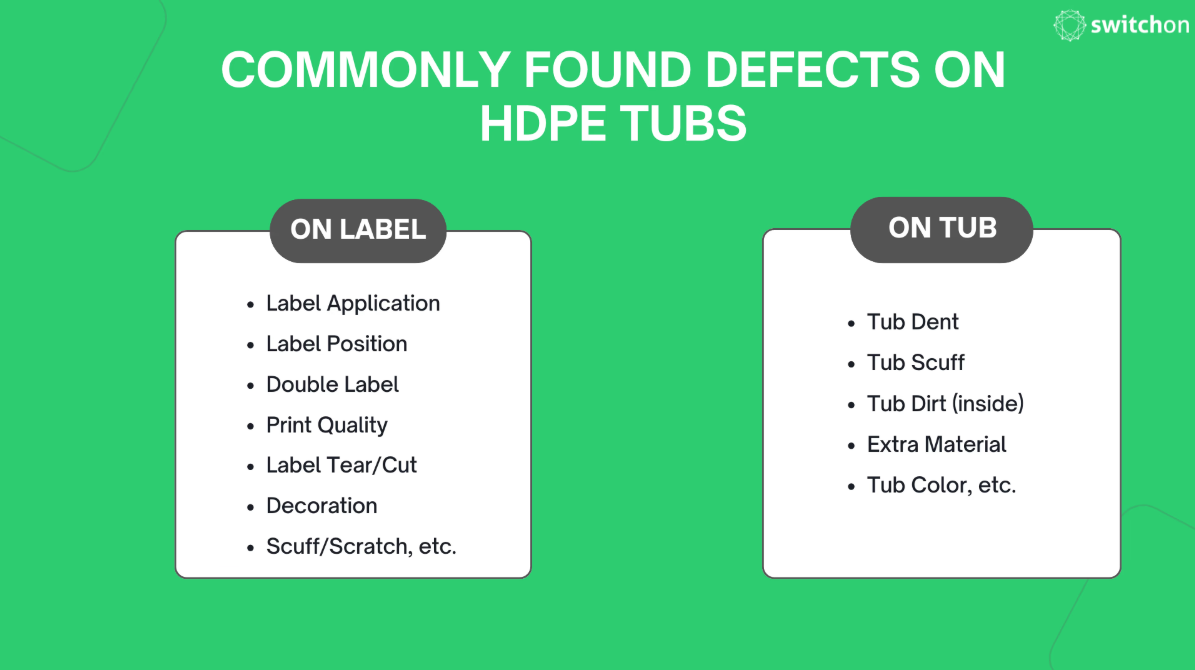

Commonly Found Defects on HDPE Tubs

Let’s take a closer look at the most commonly found defects in HDPE tubs, which can impact product quality, functionality, and customer satisfaction:

Commonly Found Defects on HDPE Tubs

Even under ideal conditions, where standardized equipment and high-quality raw materials are used, defects in HDPE tubs can still occur due to minor inconsistencies in the production process. Here’s how:

Moulding Process Variations

Slight variations in moulding parameters, such as temperature, pressure, or cooling time, can cause imperfections like minor shape deformations or uneven surfaces, even with advanced machinery.

Tooling Wear and Tear

Over time, moulds and equipment may experience wear and tear, leading to small defects like burrs or extra material on the tub edges.

Micro-contaminants in Raw Material

Even with high-quality raw materials, trace contaminants or minor inconsistencies in the resin can lead to defects, such as weak spots or discoloration.

Environmental Micro factors

Variations in ambient production conditions, like slight temperature or humidity fluctuations, can subtly affect the quality of the tubs during molding.

Labeling Issues

Label misalignment, wrinkles, or tears often occur during the labeling process if the equipment is not calibrated correctly or if the labels themselves are defective.

Operational Errors

Inconsistent machine operations, poor maintenance, or operator errors during production or labeling can result in defects like misaligned labels, incomplete seals, or surface scuffs.

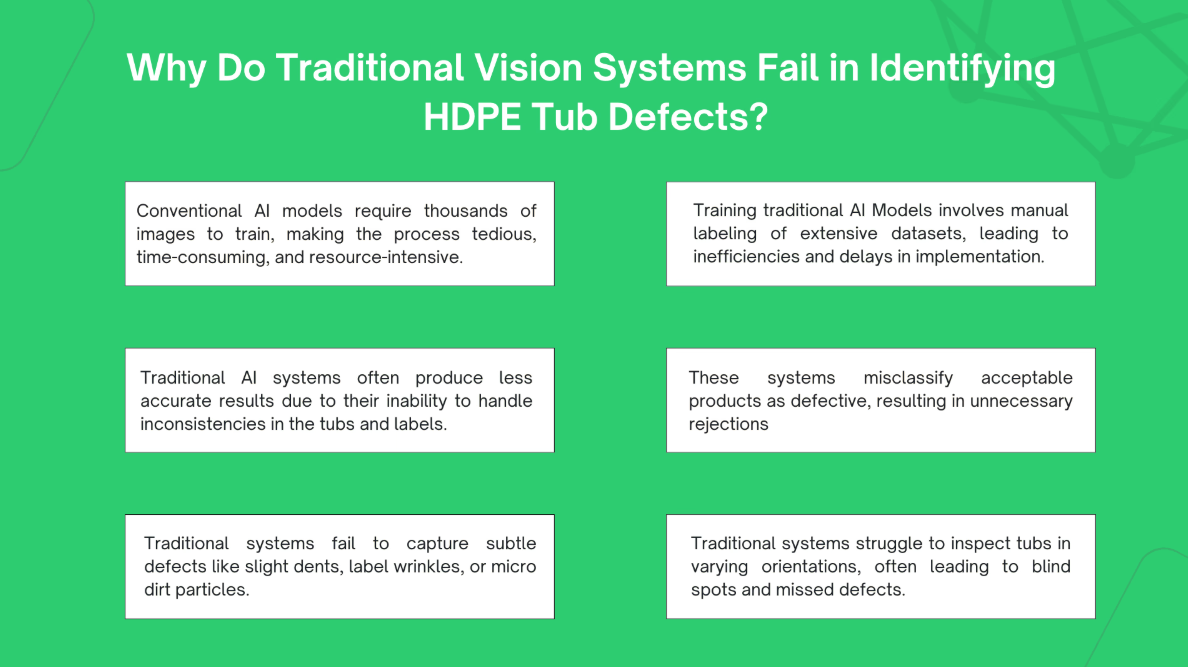

Why Do Traditional Vision Systems Fail in Identifying HDPE Tub Defects?

Traditional vision systems often fall short in detecting defects in HDPE tubs due to several limitations in their technology and approach. Below are the key reasons why they fail:

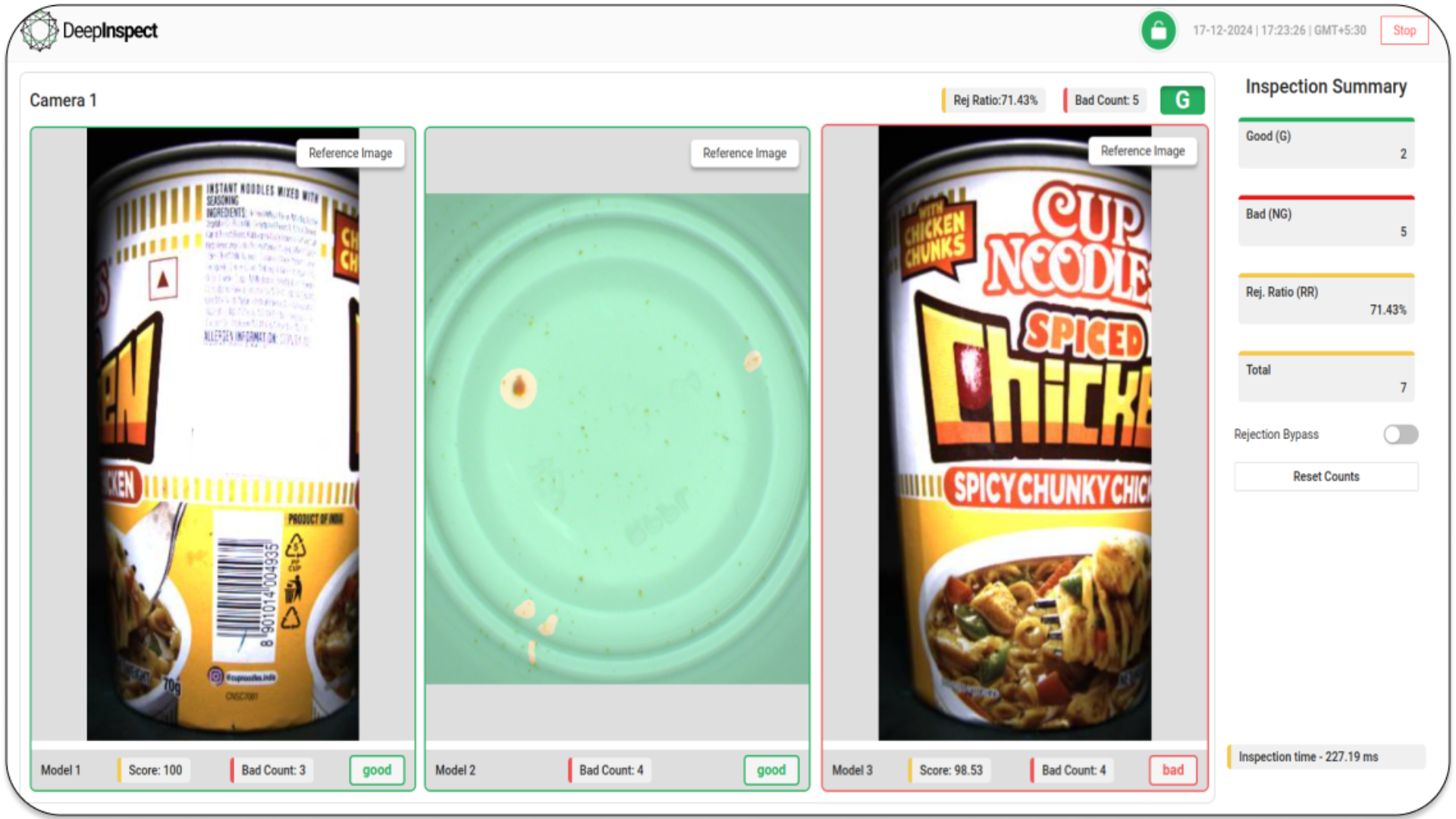

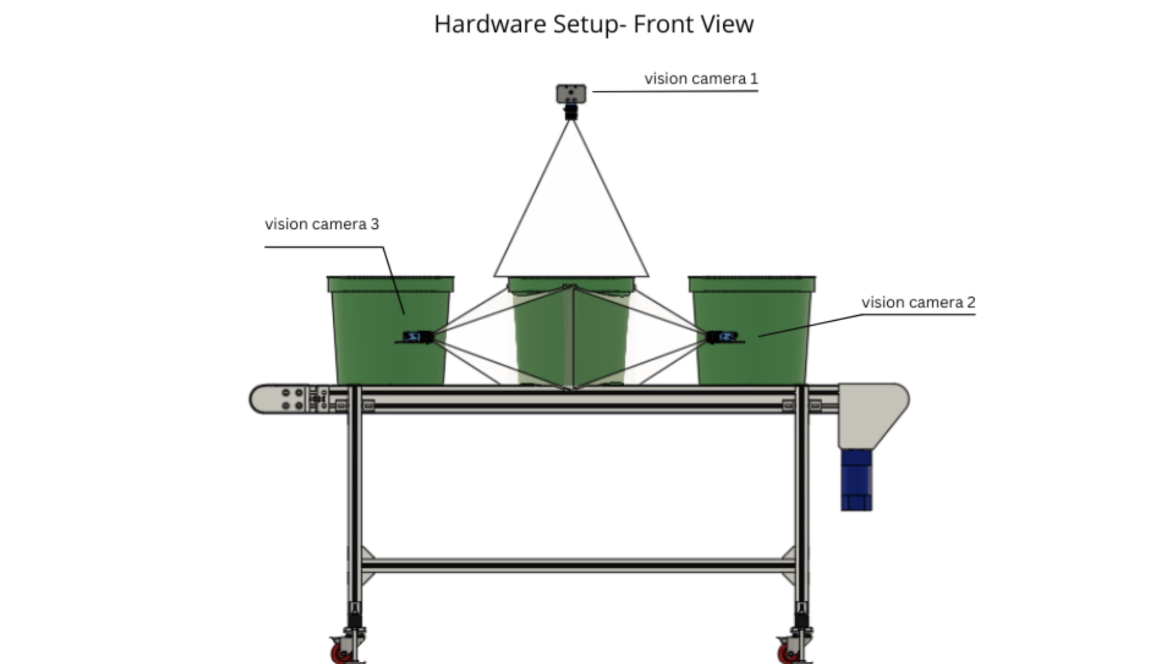

How DeepInspect® is Helping Manufacturers Overcome These Challenges

The AI-powered visual quality inspection software, DeepInspect®, only requires less than 200 good HDPE tub images for model training, making it highly efficient and easy to implement. The system uses three cameras—one on top and two on the sides (number of cameras are expandable based on scope of inspection)— to inspect tubs moving along a conveyor at pre-determined line speeds. As tubs reach the inspection station, the cameras capture high-resolution images, enabling the system to detect defects such as dents, dirt, misaligned labels, wrinkles, and more. With 99.5% accuracy and less than 0.5% false positives, defective tubs are quickly identified, and the system triggers a rejection mechanism to ensure only flawless products reach consumers.

The Setup

DeepInspect® Software

Industrial Controller with i5 and GPU

Industrial Machine Vision Lights

Industrial Camera

Mitsubishi IO Module

How DeepInspect® is Helping Manufacturers Overcome These Challenges

The AI-powered visual quality inspection software, DeepInspect®, only requires less than 200 good HDPE tub images for model training, making it highly efficient and easy to implement. The system uses three cameras—one on top and two on the sides (number of cameras are expandable based on scope of inspection)— to inspect tubs moving along a conveyor at pre-determined line speeds. As tubs reach the inspection station, the cameras capture high-resolution images, enabling the system to detect defects such as dents, dirt, misaligned labels, wrinkles, and more. With 99.5% accuracy and less than 0.5% false positives, defective tubs are quickly identified, and the system triggers a rejection mechanism to ensure only flawless products reach consumers.

Why DeepInspect® for 360 Degree Tub Inspection?

Orientation is Not a Challenge with DeepInspect®:

DeepInspect’s 360-degree inspection powered by three strategically placed industrial cameras and lighting, ensures complete coverage of tubs regardless of their orientation.

Simplified Model Training

DeepInspect® requires fewer than 200 good tub images for model training, making it easy and efficient to implement. The model can be trained in less than 45 minutes

Ability to Detect Minor Defects

DeepInspect® excels at capturing even the most subtle defects, such as slight dents, label wrinkles, and micro dirt particles, detecting imperfections as small as 150 microns.

Unmatched Accuracy and Reliability

DeepInspect® delivers 99.5% accuracy in defect detection with less than 0.5% false positive rate, ensuring precise quality control and minimizing unnecessary rejections.

Conclusion:

The DeepInspect® system is enhancing HDPE tub inspection in the FMCG industry. Its ability to detect a wide range of defects with high precision, regardless of tub orientation, ensures compliance with industry standards while reducing human errors, waste, and downtime. By leveraging DeepInspect, manufacturers can effectively address critical quality control challenges and maintain operational excellence.

Let's Discuss How We Can Transform Your Operations!

FAQ’s :

DeepInspect uses readily available industrial-grade hardware to ensure high repeatability and long lifespan. We provide a basic kit to help you get started, which includes a controller, camera, lights, and a PLC.

DeepInspect supports inspection speeds of up to 1000 parts per minute. The final speed depends on various factors, such as the number of cameras, lighting, and other line conditions. If you have a requirement above 1000 PPM, please contact us.

We support Area Scan, Line Scan, and Thermal cameras. Our software is compatible with industry-standard vendors like Basler, Baumer, Allied Vision, FLIR, and others.

DeepInspect has successfully inspected over 1000 unique SKUs across automotive, pharma, electronics, and FMCG industries. Check out our [case studies](#) to learn more.